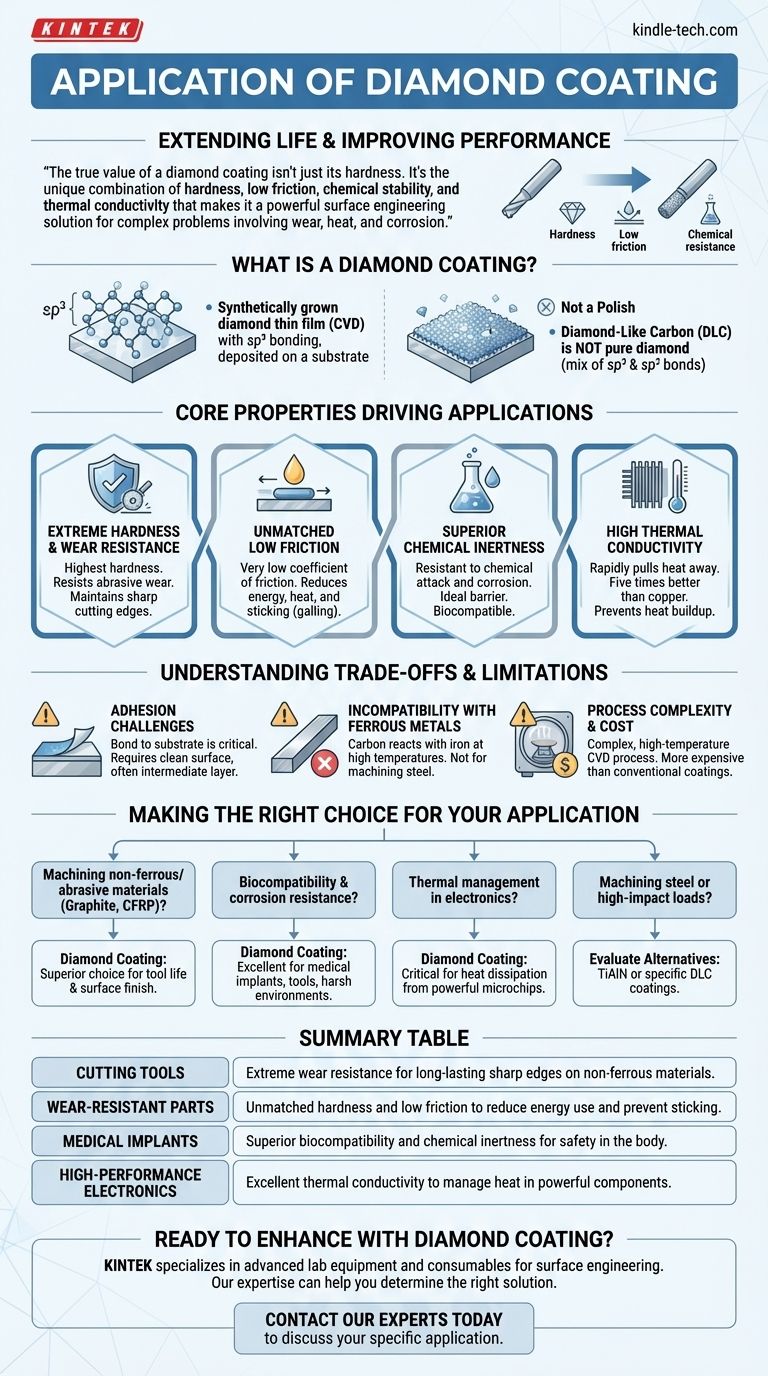

Diamond coatings are primarily applied to cutting tools, wear-resistant industrial parts, medical implants, and high-performance electronics. Their use is driven by a unique set of properties—including extreme hardness, low friction, and chemical inertness—that dramatically extend the life and improve the performance of the underlying component.

The true value of a diamond coating isn't just its hardness. It's the unique combination of hardness, low friction, chemical stability, and thermal conductivity that makes it a powerful surface engineering solution for complex problems involving wear, heat, and corrosion.

What Exactly is a Diamond Coating?

Not Just a Surface Polish

A diamond coating is not a paint or polish. It is a thin film of synthetically grown diamond, deposited atom-by-atom onto a substrate material in a vacuum chamber.

This process, most commonly Chemical Vapor Deposition (CVD), creates a film with the same carbon-atom crystal structure (sp³ bonding) as natural diamond. The result is a surface that possesses the exceptional properties of diamond, even if the bulk material underneath does not.

A Note on Diamond-Like Carbon (DLC)

It's important to distinguish true diamond coatings from Diamond-Like Carbon (DLC). DLC is an amorphous film with a mix of diamond-like (sp³) and graphite-like (sp²) bonds. While it shares some benefits like low friction and hardness, it is not pure diamond and has a different performance profile.

Core Properties Driving the Applications

The reason diamond coatings are so versatile is that they solve multiple engineering problems at once.

Extreme Hardness and Wear Resistance

This is the most well-known property. With the highest hardness of any known material, diamond coatings provide exceptional resistance to abrasive wear.

This allows tools to maintain a sharp cutting edge for far longer and protects components from being worn down by contact or abrasive particles.

Unmatched Low Friction

Diamond has an incredibly low coefficient of friction, especially in dry conditions. This is often compared to wet ice on wet ice.

This property reduces the energy needed to operate moving parts, minimizes heat generation from friction, and prevents material from sticking to the surface (a phenomenon known as galling).

Superior Chemical Inertness

Diamond is extremely resistant to chemical attack and corrosion. It does not react with most acids, bases, or other corrosive agents.

This makes it an ideal barrier between a component and a harsh environment. It's also a key reason for its biocompatibility, as it does not react with bodily fluids or tissues.

High Thermal Conductivity

Contrary to what many assume, diamond is one of the best thermal conductors known—five times better than copper.

It can rapidly pull heat away from a concentrated source and spread it across a wider area. This is critical for preventing heat buildup in applications like high-speed cutting and high-power electronics.

Understanding the Trade-offs and Limitations

While powerful, diamond coatings are not a universal solution. Understanding their limitations is critical for successful application.

The Challenge of Adhesion

The coating is only as effective as its bond to the substrate. Poor adhesion will lead to flaking and premature failure. Ensuring a clean surface and often an intermediate bonding layer is crucial.

Incompatibility with Ferrous Metals

Diamond coatings are generally not suitable for machining steel or other iron-based alloys. At the high temperatures generated during cutting, the carbon in the diamond reacts with the iron, causing the coating to rapidly degrade. Other coatings like TiN or TiAlN are used for these materials.

Process Complexity and Cost

Applying a high-quality CVD diamond coating is a complex, high-temperature vacuum process. This makes it a more expensive solution compared to many conventional hard coatings, so its use must be justified by significant performance gains.

Making the Right Choice for Your Application

Selecting the right surface treatment depends entirely on the specific problem you are trying to solve.

- If your primary focus is machining non-ferrous or abrasive materials (like graphite or CFRP): Diamond coating is the superior choice for extending tool life and achieving a high-quality surface finish.

- If your primary focus is biocompatibility and corrosion resistance: The inert nature of diamond makes it an excellent candidate for medical implants, surgical tools, and components in harsh chemical environments.

- If your primary focus is thermal management in electronics: The exceptional thermal conductivity of diamond provides a critical solution for dissipating heat from powerful microchips and laser diodes.

- If your primary focus is machining steel or managing high-impact loads: You must evaluate alternatives like TiAlN or specific DLC coatings, as pure diamond is likely not the optimal choice.

Ultimately, understanding these core properties allows you to leverage diamond coatings not just as a protective layer, but as a strategic tool for solving complex engineering challenges.

Summary Table:

| Application Area | Key Benefit of Diamond Coating |

|---|---|

| Cutting Tools | Extreme wear resistance for long-lasting sharp edges on non-ferrous materials. |

| Wear-Resistant Parts | Unmatched hardness and low friction to reduce energy use and prevent sticking. |

| Medical Implants | Superior biocompatibility and chemical inertness for safety in the body. |

| High-Performance Electronics | Excellent thermal conductivity to manage heat in powerful components. |

Ready to enhance your components with the superior performance of a diamond coating?

KINTEK specializes in advanced lab equipment and consumables for surface engineering. Our expertise can help you determine if a diamond coating is the right solution to extend the life of your cutting tools, improve the reliability of your medical devices, or solve challenging thermal management problems.

Contact our experts today to discuss your specific application and discover the benefits we can bring to your laboratory or production process.

Visual Guide

Related Products

- CVD Diamond for Thermal Management Applications

- CVD Diamond Dressing Tools for Precision Applications

- CVD Diamond Domes for Industrial and Scientific Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What is the main difference between CVD and natural diamond? Origin, Purity, and Value Explained

- What is CVD diamond? The Ultimate Guide to Lab-Grown Diamonds and Their Uses

- Are CVD diamonds better than HPHT? The Real Truth About Lab-Grown Diamond Quality

- What is the future value of lab grown diamond? Understanding Its Depreciating Financial Worth

- What are the common sources of contamination during CVD diamond growth? Improve Purity and Quality Control