In thermal processing, a furnace atmosphere is the specific gas or mixture of gases intentionally introduced into a furnace chamber. This controlled environment is distinct from ambient air and is essential for manipulating the outcome of the heat treatment process, such as protecting a material's surface, preventing oxidation, or deliberately altering its surface chemistry.

The core purpose of a furnace atmosphere is to transform a furnace from a simple oven into a precision tool. By controlling the gaseous environment, you gain direct control over the chemical reactions that occur on a material's surface at high temperatures.

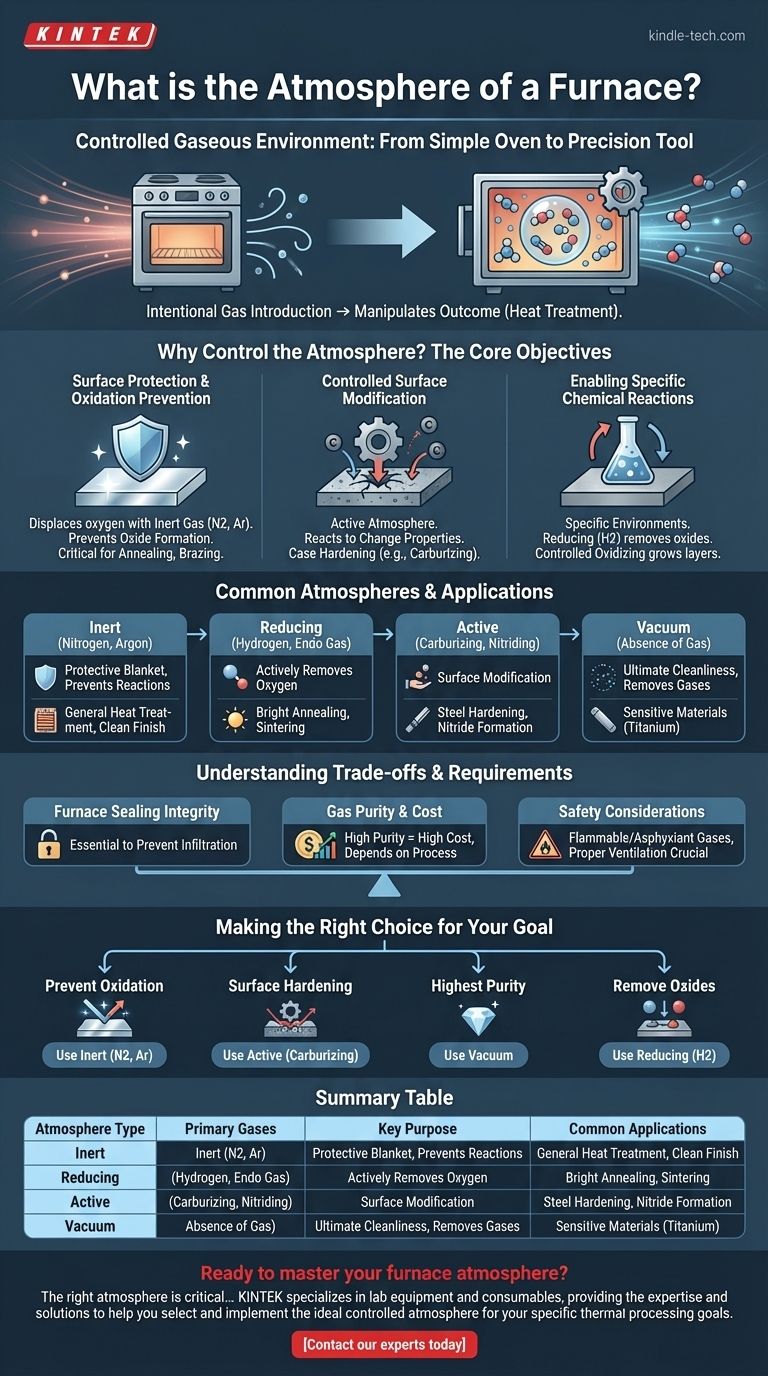

Why Control the Atmosphere? The Core Objectives

Simply heating a material in air can cause undesirable effects like scaling and discoloration due to oxidation. A controlled atmosphere is used to manage these reactions for a specific, repeatable outcome.

Surface Protection and Oxidation Prevention

The most common reason to use a controlled atmosphere is to protect the material. By displacing oxygen with an inert gas like nitrogen or argon, you prevent the formation of oxides on the material's surface.

This is critical for processes like annealing or brazing, where maintaining a clean, bright surface finish is paramount for the component's final properties and appearance.

Controlled Surface Modification

A furnace atmosphere can also be "active," meaning it is designed to react with the material to change its surface properties. This process is known as case hardening.

The most well-known example is carburizing. An atmosphere rich in carbon monoxide and hydrocarbons is used to diffuse carbon atoms into the surface of steel, creating a hard, wear-resistant outer layer while maintaining a tougher core.

Enabling Specific Chemical Reactions

Some advanced materials processing requires highly specific environments. A reducing atmosphere, which typically contains hydrogen, is used to actively remove oxides from a surface.

Conversely, a controlled oxidizing atmosphere might be used to grow a specific, thin oxide layer on a material for applications in electronics or corrosion resistance.

Common Atmospheres and Their Applications

The choice of atmosphere is dictated entirely by the material being treated and the desired outcome.

Inert Atmospheres (Nitrogen, Argon)

These gases are chemically inactive and serve primarily as a protective blanket. They displace oxygen and prevent unwanted reactions. They are the go-to choice for general-purpose heat treatment where a clean finish is the main goal.

Reducing Atmospheres (Hydrogen, Endothermic Gas)

These atmospheres actively remove oxygen. A mix of hydrogen and nitrogen is common for the bright annealing of stainless steels. Endothermic gas, produced by reacting air and natural gas, is a cost-effective reducing atmosphere widely used as a carrier gas in carburizing.

Active Atmospheres (Carburizing, Nitriding)

These are designed for surface modification. A carburizing atmosphere adds carbon to steel. A nitriding atmosphere uses nitrogen (often from dissociated ammonia) to form hard nitrides on the surface of specialty steels.

Vacuum

Creating a vacuum is the ultimate way to create a clean atmosphere by removing virtually all gases. It is used for extremely sensitive materials that cannot tolerate any surface reaction, such as titanium or refractory metals.

Understanding the Trade-offs and Requirements

Implementing a controlled atmosphere is not as simple as pumping gas into a box. It requires specific equipment and careful consideration of several factors.

Furnace Sealing Integrity

A controlled atmosphere is only effective if the furnace chamber is properly sealed. Any air leaks will contaminate the atmosphere and compromise the entire process. High-temperature gaskets and positive pressure inside the furnace are essential to prevent infiltration.

Gas Purity and Cost

High-purity gases like argon can be expensive. The required level of purity depends on the sensitivity of your process. For general-purpose annealing, industrial-grade nitrogen may be sufficient, but for aerospace components, a higher purity is non-negotiable.

Safety Considerations

Many atmospheric gases introduce significant safety hazards. Hydrogen is highly flammable, while nitrogen and argon are simple asphyxiants. Proper ventilation, leak detection, and exhaust gas management systems are critical for safe operation.

Making the Right Choice for Your Goal

Your choice of atmosphere directly determines the chemical result of your thermal process. The equipment and the gas must be matched to the objective.

- If your primary focus is preventing oxidation and discoloration: Use an inert atmosphere like nitrogen or argon for a clean, protected surface during processes like annealing or brazing.

- If your primary focus is surface hardening of steel: A carburizing atmosphere is necessary to introduce carbon into the material's surface and create a wear-resistant case.

- If your primary focus is achieving the highest purity and cleanliness: A high-vacuum environment is the most effective way to remove nearly all reactive gas contaminants for sensitive materials.

- If your primary focus is actively removing surface oxides: A reducing atmosphere containing hydrogen is required for processes like bright annealing or sintering powdered metals.

Ultimately, mastering the furnace atmosphere allows you to precisely engineer the surface of your material to meet demanding performance requirements.

Summary Table:

| Atmosphere Type | Primary Gases | Key Purpose | Common Applications |

|---|---|---|---|

| Inert | Nitrogen, Argon | Prevent oxidation & discoloration | Annealing, Brazing |

| Reducing | Hydrogen, Endothermic Gas | Remove existing oxides | Bright Annealing, Sintering |

| Active | Carbon Monoxide, Ammonia | Modify surface chemistry | Carburizing, Nitriding |

| Vacuum | N/A (absence of gas) | Achieve ultimate purity | Processing sensitive materials (e.g., Titanium) |

Ready to master your furnace atmosphere?

The right atmosphere is critical for achieving the precise material properties you need, from preventing oxidation to enabling advanced surface hardening. KINTEK specializes in lab equipment and consumables, providing the expertise and solutions to help you select and implement the ideal controlled atmosphere for your specific thermal processing goals.

Contact our experts today to discuss how we can support your laboratory's success.

Visual Guide

Related Products

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the role of nitrogen in annealing process? Creating a Controlled, Protective Atmosphere

- What is the composition and role of air in controlled furnace atmospheres? Master Your Process with Precise Gas Control

- How do high-temperature atmosphere annealing furnaces ensure electrocatalytic activity? Optimize Your Metal Nitrides

- How does an atmosphere heating furnace used for surface pre-oxidation assist in subsequent nitriding? Boost Surface Activity

- What is brazing? A Guide to Strong, Precise Metal Joining for High-Performance Applications

- Why is a vacuum or atmosphere furnace required for SiBCN pyrolysis? Mastering Precision for Superior Ceramics

- Why is a controlled atmosphere tube furnace required for HPS catalysts? Ensure Optimal Metal Site Activation

- What is a reducing atmosphere? Optimize Material Processing by Preventing Oxidation