The primary benefits of an induction furnace are its exceptional precision, high energy efficiency, and its clean, safe method of operation. Because it generates heat directly within the metal charge using electromagnetism instead of an external flame or arc, it offers unparalleled control over the entire melting process, resulting in higher quality products and a safer work environment.

Unlike traditional furnaces that heat from the outside in, an induction furnace uses electromagnetism to generate heat within the material itself. This fundamental difference is the source of its core advantages in control, speed, and purity for metallurgical applications.

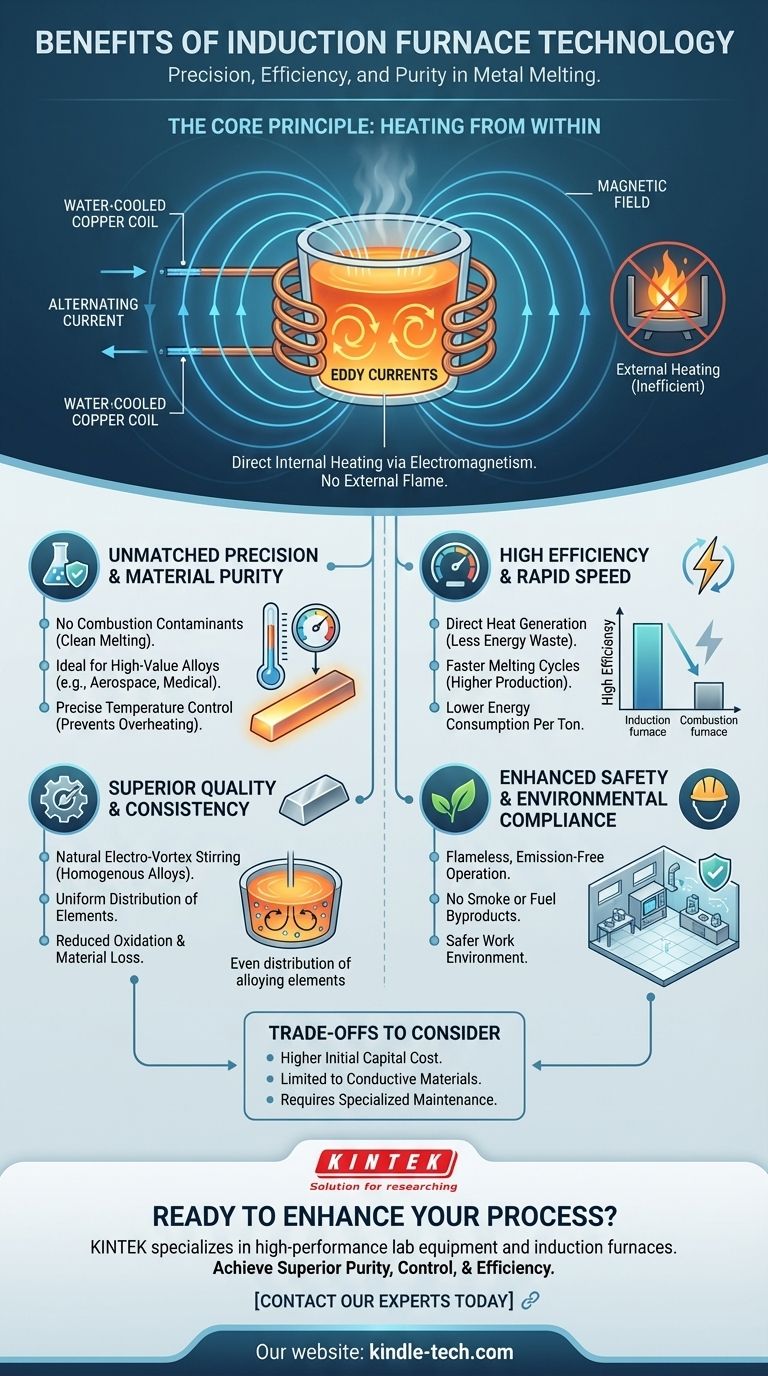

The Core Principle: Heating from Within

The unique advantages of induction technology stem directly from its method of heating. It is not an incremental improvement over older methods; it is a fundamentally different approach.

How Electromagnetic Induction Works

An induction furnace utilizes a powerful, water-cooled copper coil. A high-frequency alternating current is passed through this coil, creating a dynamic and powerful magnetic field.

When a conductive material, such as metal scrap or ingots, is placed inside this field, the magnetic field induces strong electrical currents (known as eddy currents) within the metal itself. The metal's natural resistance to these currents generates intense, rapid, and precise heat.

The Impact on Speed and Efficiency

Because the heat is generated inside the charge, the melting process is remarkably fast and energy-efficient. There is very little wasted energy heating the furnace chamber or the surrounding air, as is common with combustion-based systems.

This direct heating method leads to significantly higher production efficiency and lower overall energy consumption per ton of metal melted.

Unmatched Precision and Material Quality

For applications involving valuable alloys or strict metallurgical specifications, control is paramount. Induction furnaces provide a level of control that combustion furnaces cannot match.

Preventing Contamination

The process is entirely free of combustion. There are no flames, smoke, or fuel byproducts to introduce impurities like carbon or sulfur into the melt.

This makes it the ideal choice for applications where metal purity is a critical concern, such as in aerospace, medical, or specialty alloy manufacturing.

Minimizing Oxidation and Element Loss

The precise and rapid temperature control prevents overheating. This minimizes the loss of valuable and easily oxidized alloying elements.

With no direct flame impinging on the metal, both oxidation and decarburization are drastically reduced, saving material and ensuring the final product meets its chemical specifications.

Ensuring Alloy Homogeneity

The electromagnetic field that heats the metal also creates a natural stirring action within the molten bath. This electro-vortex effect ensures that all alloying elements are distributed evenly, resulting in a perfectly uniform and homogenous final product.

Understanding the Trade-offs

While induction technology offers significant advantages, it is essential to understand its specific operational context and limitations.

Higher Initial Capital Cost

The advanced power electronics, precision coils, and cooling systems required for an induction furnace typically result in a higher upfront investment compared to simpler, fuel-fired furnaces.

Material Constraints

Induction heating is only effective on electrically conductive materials. It is the ideal technology for metals but is not suitable for melting non-conductive materials like glass or certain ceramics.

Maintenance Complexity

The high-frequency power supplies and water-cooling circuits are sophisticated systems. They require specialized knowledge for proper maintenance and repair, which can be a consideration for some facilities.

Making the Right Choice for Your Application

Selecting the right furnace technology depends entirely on your operational priorities and the materials you are processing.

- If your primary focus is high-purity alloys or specialty metals: The contamination-free, precision-controlled melting environment of an induction furnace is non-negotiable.

- If your primary focus is high-volume production and efficiency: The rapid heating cycles, low energy consumption, and reduced material loss offer a compelling return on investment.

- If your primary focus is workplace safety and environmental compliance: The flameless, emission-free operation makes the induction furnace the superior choice for a modern industrial facility.

Ultimately, adopting induction furnace technology is a strategic decision to prioritize material quality, operational efficiency, and a safer, cleaner work environment.

Summary Table:

| Benefit | Key Advantage |

|---|---|

| Material Purity | No combustion contaminants; ideal for high-value alloys. |

| Process Control | Precise temperature regulation and natural stirring action. |

| Energy Efficiency | Direct internal heating minimizes energy waste. |

| Operational Safety | Flameless, emission-free operation enhances workplace safety. |

Ready to enhance your metal melting process with precision and efficiency?

KINTEK specializes in high-performance lab equipment, including induction furnaces designed for superior results. Our solutions deliver the purity, control, and efficiency your laboratory demands, ensuring you achieve the highest quality outcomes for your specialized alloys and metals.

Contact our experts today to find the perfect induction furnace for your application and discover how we can support your laboratory's success.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does a vacuum hot pressing furnace facilitate nanocrystalline structures? Enhance Fe–Cu–Ni–Sn–VN Composite Hardness

- What role does a vacuum hot pressing sintering furnace play in the fabrication of CuCrFeMnNi alloys? Achieve High Purity

- How does the vacuum environment within a hot-pressing furnace improve the performance of B4C/Al composites? Boost Density

- How does the mechanical pressure from a vacuum hot-pressing furnace facilitate the densification of B4C/Al composites?

- How does the degassing stage in a vacuum hot press (VHP) optimize diamond/aluminum composite performance?