The best media for a ball mill is not a single material, but rather a choice dictated entirely by your specific application. The two most dominant and effective options are steel balls and ceramic balls. Steel is the superior choice for high-impact grinding of hard materials due to its high density, while ceramic is essential for applications where preventing product contamination is the primary goal.

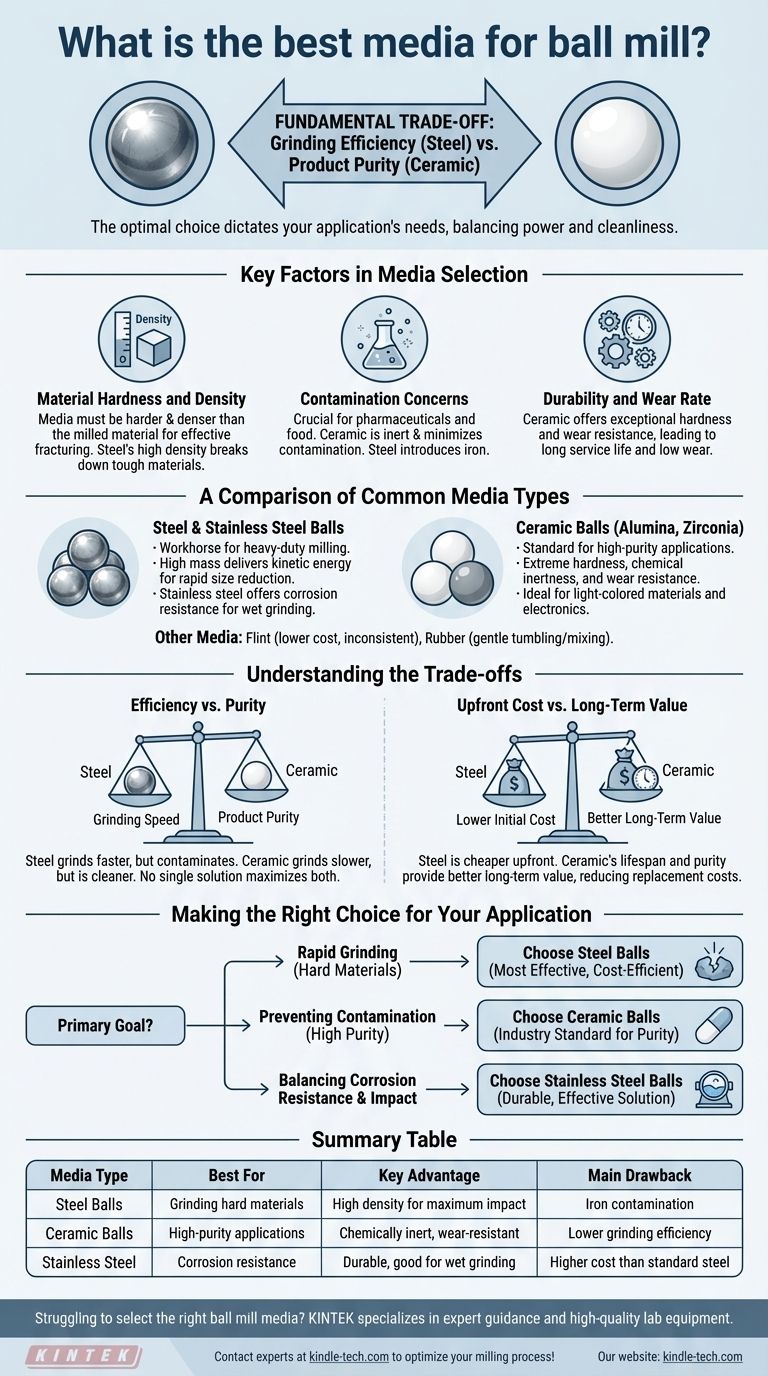

The optimal ball mill media represents a fundamental trade-off between grinding efficiency and product purity. Steel balls offer maximum grinding power and speed, while ceramic balls deliver the cleanest, most uncontaminated final product.

Key Factors in Media Selection

To determine the ideal media, you must first assess the demands of your process. The material being milled, its hardness, and the final product's quality standards will guide your decision.

Material Hardness and Density

The grinding media must be significantly harder and denser than the material you are milling. This differential is what allows the media to effectively fracture and reduce the particle size of the charge.

Steel's high density makes it exceptionally effective for breaking down tough, coarse, or highly resistant materials that require significant impact force.

Contamination Concerns

This is often the most critical factor. During the milling process, the media will inevitably wear down, introducing microscopic particles of itself into your product.

If you are milling pharmaceuticals, food-grade materials, or high-purity chemicals, ceramic media is non-negotiable. It is chemically inert and minimizes contamination. Standard steel media, by contrast, will introduce iron into the mix.

Durability and Wear Rate

The media's wear rate impacts both operating costs and product purity. Low-quality media that wears quickly must be replaced more often and introduces more contaminants.

Ceramic balls are known for their exceptional hardness and high resistance to abrasion, giving them a very long service life and a low rate of wear.

A Comparison of Common Media Types

While many materials can be used, the choice almost always comes down to a select few, each with distinct advantages.

Steel and Stainless Steel Balls

Steel balls are the workhorse of heavy-duty milling. Their high mass delivers the kinetic energy needed for rapid size reduction.

For applications where rust is a concern but the high impact of steel is still needed, stainless steel balls offer a compromise, providing better corrosion resistance than standard carbon steel.

Ceramic Balls

Ceramic media, such as alumina or zirconia, is the standard for high-purity applications. It is prized for its extreme hardness, wear resistance, and chemical inertness.

This makes it the ideal choice for light-colored materials, electronics, and any product where even trace amounts of iron contamination would be unacceptable.

Other Media (Flint, Rubber)

Materials like flint pebbles are a natural, lower-cost alternative to manufactured media but offer less consistent performance and shape.

Rubber balls are a highly specialized option used for applications that require gentle tumbling and mixing rather than aggressive size reduction.

Understanding the Trade-offs

Choosing a grinding media is a balancing act. Understanding the inherent compromises is key to avoiding costly errors and process inefficiencies.

Efficiency vs. Purity

This is the central dilemma. Steel's density means it grinds faster and more efficiently than ceramic of the same size. However, this efficiency comes at the cost of iron contamination.

You must decide which is more critical for your process: speed or purity. There is no solution that maximizes both.

Upfront Cost vs. Long-Term Value

Generally, steel balls have a lower initial purchase price. High-performance ceramic media can represent a significant upfront investment.

However, the longer lifespan and superior purity of ceramic can provide better long-term value, reducing media replacement costs and preventing batch rejection due to contamination.

Making the Right Choice for Your Application

Select your media based on a clear understanding of your primary operational goal.

- If your primary focus is rapid grinding of hard materials: Steel balls are your most effective and cost-efficient choice.

- If your primary focus is preventing product contamination: Ceramic balls are the industry standard for ensuring high purity.

- If you are balancing corrosion resistance with high-impact grinding: Stainless steel balls provide a durable and effective solution.

Ultimately, matching the media's properties to your material's demands and your product's purity standards is the key to successful milling.

Summary Table:

| Media Type | Best For | Key Advantage | Main Drawback |

|---|---|---|---|

| Steel Balls | Grinding hard materials | High density for maximum impact | Iron contamination |

| Ceramic Balls | High-purity applications | Chemically inert, wear-resistant | Lower grinding efficiency |

| Stainless Steel | Corrosion resistance | Durable, good for wet grinding | Higher cost than standard steel |

Struggling to select the right ball mill media for your specific lab materials? KINTEK specializes in lab equipment and consumables, providing expert guidance and high-quality grinding media tailored to your application—whether you prioritize maximum grinding power with steel or absolute product purity with ceramic. Contact our experts today to optimize your milling process and achieve superior results!

Visual Guide

Related Products

- Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

- Three-dimensional electromagnetic sieving instrument

- Laboratory Disc Cup Vibratory Mill for Sample Grinding

- Custom PTFE Teflon Parts Manufacturer Grinding Bowl

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

People Also Ask

- Why are tungsten carbide grinding balls selected for silicon nitride-alumina synthesis? Achieve 99.95% Ceramic Purity

- What role does a planetary ball mill play in the synthesis of Li6PS5Br? Revolutionize Solid-State Electrolyte Production

- What core function does a high-power ball mill perform for nano-lead powder? Optimize Your Gamma-Ray Shielding

- What is the primary function of a planetary ball mill during Mo-La2O3 mixing? Achieve Uniform Powder Dispersion

- What is the primary function of a planetary ball mill for LGPS preparation? Unlock High-Energy Mechanochemical Synthesis

- What is the function of a high-energy ball mill in NiCr composites? Optimize Synthesis with Mechanical Activation

- What is the primary purpose of using a planetary ball mill for iridium powder? Achieve Microscopic Mixing Uniformity

- What is the primary role of a wet planetary ball mill? Optimize NaFePO4 (Maricite) Precursor Synthesis