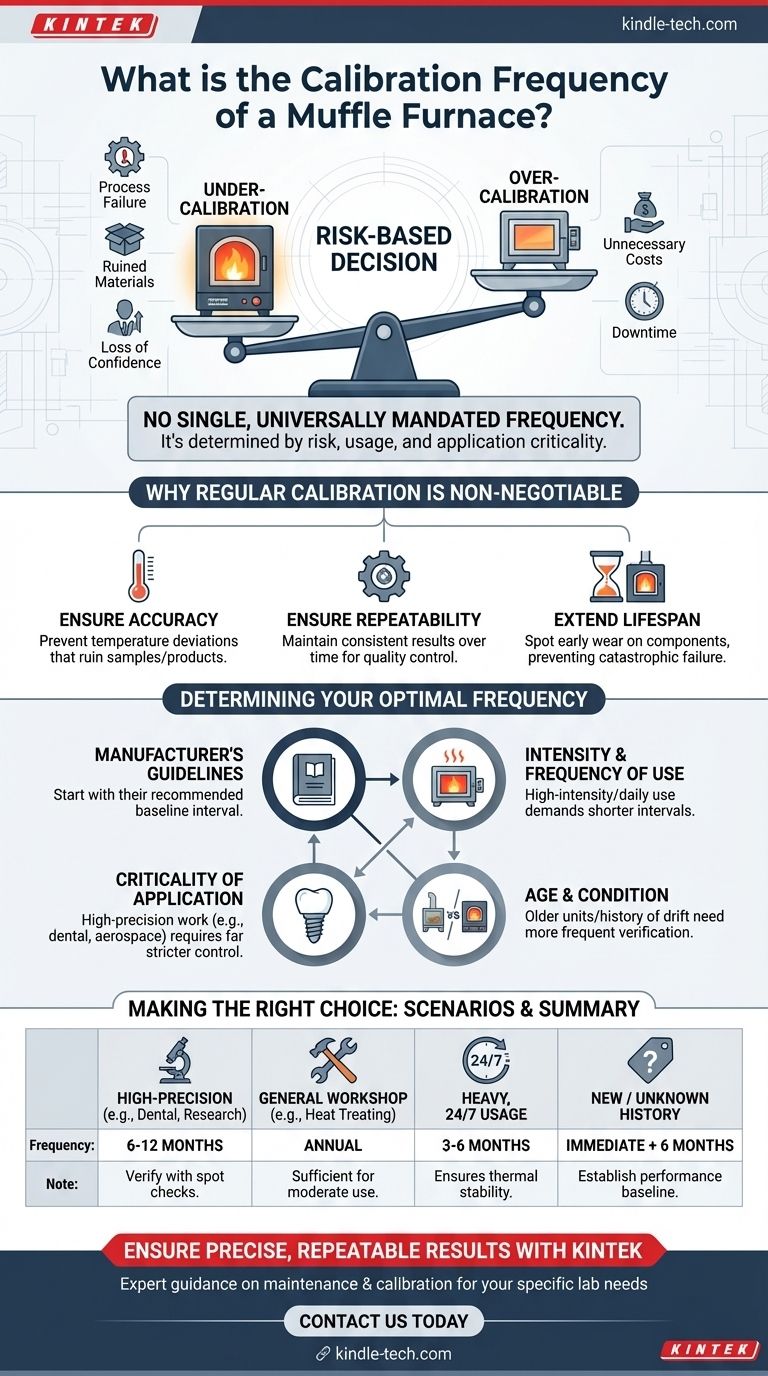

Ultimately, there is no single, universally mandated calibration frequency for a muffle furnace. The correct interval is not a fixed number but is instead determined by a combination of manufacturer recommendations, the intensity of use, and the criticality of the applications it serves. Regular calibration is essential to ensure temperature accuracy, prevent damage to samples, and maintain process integrity.

The core principle is that calibration frequency is a risk-based decision. The more critical your process and the more intensive the furnace usage, the shorter the interval between calibrations must be to guarantee reliable and accurate thermal processing.

Why Regular Calibration is Non-Negotiable

A muffle furnace is a precision instrument. Its entire purpose is to hold a specific temperature accurately over time. Without periodic verification, you are operating on an assumption of accuracy that can lead to significant failures.

The Impact of Inaccurate Temperature

An uncalibrated furnace can result in temperature deviation, where the displayed temperature does not match the actual internal temperature. This can lead to ruined restorations in a dental lab, failed experiments in a research setting, or inconsistent material properties in a workshop.

Ensuring Process Repeatability

For any quality management system, whether in a lab or a production environment, process control is key. Regular calibration ensures that a process run today at 800°C is identical to one run six months from now, providing consistent and repeatable results.

Extending Equipment Lifespan

Calibration often occurs as part of a larger preventative maintenance schedule. During this service, technicians can spot early signs of wear on components like thermocouples or heating elements, allowing for proactive repairs that prevent catastrophic failure and extend the furnace's operational life.

Determining Your Optimal Calibration Frequency

Instead of searching for a single answer, you must evaluate your specific operational context. Use the following factors to establish a baseline schedule for your equipment.

Manufacturer's Guidelines

The furnace manufacturer's manual is the first place you should look. They will provide a recommended starting interval based on their equipment's design and intended use. This is your most reliable initial benchmark.

Intensity and Frequency of Use

A furnace running multiple cycles daily near its maximum temperature will experience more component drift and wear than a furnace used twice a week at moderate temperatures. High-intensity use demands more frequent calibration.

Criticality of the Application

The required precision of your work is a major driver. A dental furnace producing medical-grade prosthetics requires far stricter control than a furnace used for simple annealing in a hobbyist workshop. Higher criticality means shorter calibration intervals.

Age and Condition of the Furnace

Older furnaces or those with a history of temperature fluctuations are more likely to drift out of specification. These units require more frequent verification to ensure they remain accurate. A brand-new furnace may also benefit from a follow-up calibration after its initial months of service to establish a performance baseline.

Understanding the Trade-offs

Choosing a calibration schedule involves balancing risk, cost, and operational uptime.

The Risk of Under-Calibration

Calibrating too infrequently is the highest-risk approach. It saves minimal cost in the short term but exposes you to process failures, ruined materials, and a complete loss of confidence in your results. For any professional application, this is an unacceptable risk.

The Cost of Over-Calibration

Calibrating too frequently (e.g., monthly when annually is sufficient) poses little technical risk but incurs unnecessary costs. This includes the direct cost of the calibration service and the operational cost of equipment downtime.

Ignoring Routine Maintenance

Calibration cannot be viewed in isolation. The references note the importance of regular cleaning of slag and debris. A dirty furnace with obstructed airflow or contaminated sensors will not perform accurately, even if recently calibrated. Maintenance and calibration are two parts of the same goal: reliability.

Making the Right Choice for Your Goal

Use these scenarios as a starting point to define your furnace's calibration schedule. Always document your findings and adjust the frequency based on the "as found" data from each calibration.

- If your primary focus is high-precision results (e.g., dental, research, aerospace): Start with a 6-month to 1-year interval and verify with spot checks using an independent thermocouple.

- If your primary focus is general workshop use (e.g., heat treating, ash testing): An annual calibration is often a sufficient starting point, assuming moderate usage.

- If you are managing a furnace with very heavy, 24/7 usage: A 3 to 6-month interval is a much safer benchmark to ensure thermal stability.

- If the furnace is new or its usage history is unknown: Perform an initial calibration immediately and schedule a second one in 6 months to establish a clear performance drift rate.

Proactive calibration transforms your furnace from an unknown variable into a reliable and trusted tool.

Summary Table:

| Factor | Impact on Calibration Frequency |

|---|---|

| Application Criticality | High-precision uses (e.g., dental, research) require more frequent calibration (6-12 months). |

| Intensity of Use | Heavy, daily use demands shorter intervals (3-6 months) vs. moderate use (annual). |

| Manufacturer Guidelines | Provides the essential baseline recommendation for your specific furnace model. |

| Furnace Age & Condition | Older units or those with a history of drift need more frequent verification. |

Ensure your muffle furnace delivers precise, repeatable results every time.

Don't let inaccurate temperatures compromise your samples, experiments, or production quality. At KINTEK, we specialize in providing reliable lab equipment and consumables, along with expert guidance on maintenance and calibration schedules tailored to your specific laboratory needs.

Contact us today to discuss your furnace calibration requirements and keep your processes running with confidence.

Get in touch with our experts now!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What role do high-temperature sintering furnaces play in LATP fabrication? Master Density and Ionic Conductivity

- What is dry ashing? A Reliable Method for Analyzing Inorganic Composition

- How do you maintain a muffle furnace? Ensure Safety and Maximize Equipment Lifespan

- What is the critical function of a high-temperature furnace in MEC carbon brush preparation? Optimize Bio-Anode Surface

- What are the different types of Quenchants? Choose the Right Coolant for Optimal Metal Hardening

- What design considerations are necessary for high-temperature muffle furnaces with MoSi2 heating elements?

- How does a high-temperature muffle furnace work? Achieve Contaminant-Free, Uniform Heating

- What is the function of a high-temperature muffle furnace in niobate ceramic preparation? Expert Synthesis Guide