The primary chemical method for synthesizing carbon nanotubes on a commercial scale is Chemical Vapor Deposition (CVD). While older methods like laser ablation and arc discharge exist, CVD has become the dominant industrial process because it allows for greater control over the growth process, leading to higher-quality materials with desired properties.

The challenge in producing carbon nanotubes isn't just about making them, but about making them with consistent quality and structure at scale. Chemical Vapor Deposition (CVD) is the most effective solution because it treats nanotube growth as a controllable chemical reaction, governed by precise inputs like temperature, gas flow, and catalyst choice.

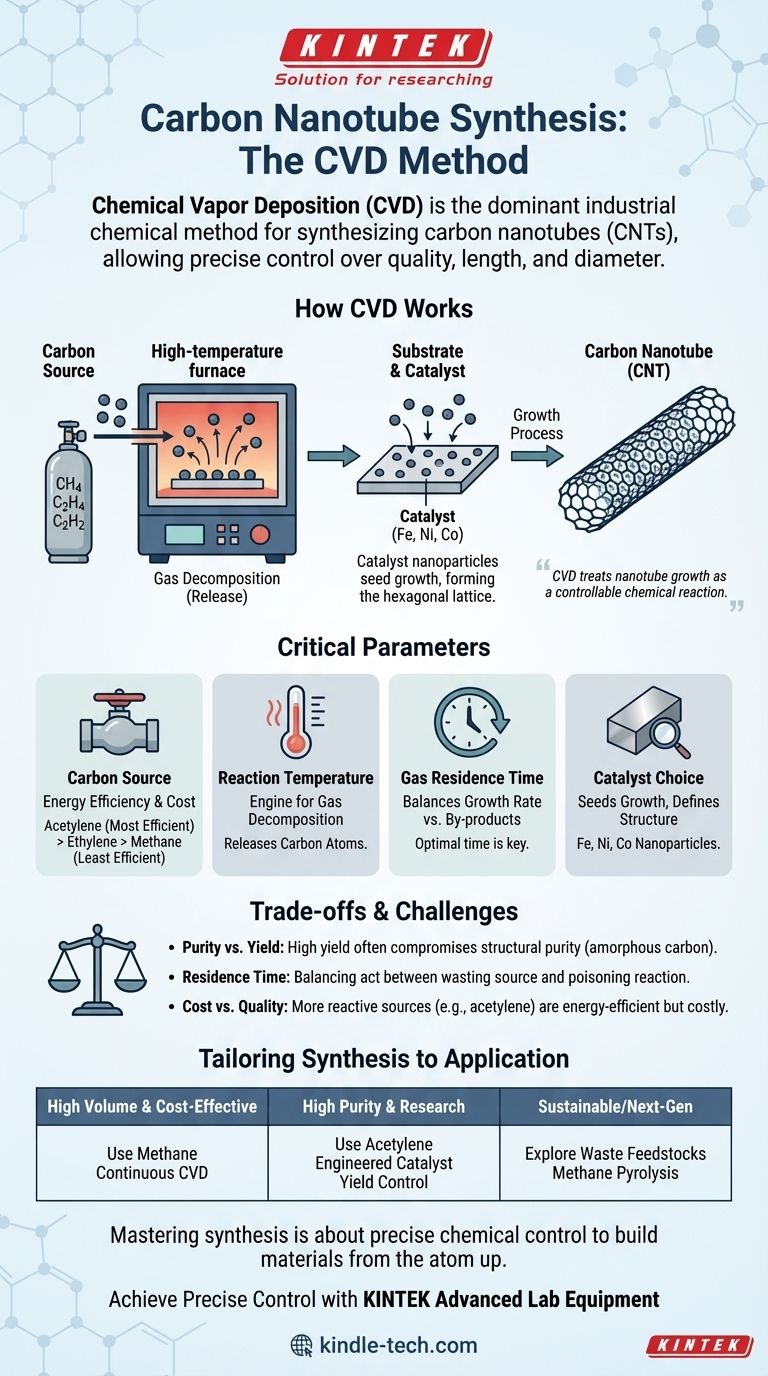

How Chemical Vapor Deposition (CVD) Works

CVD is a process where a substrate is exposed to one or more volatile chemical precursors, which react or decompose on the substrate's surface to produce the desired deposit. For carbon nanotubes, this process is tailored specifically for carbon.

The Core Principle

The synthesis takes place in a high-temperature furnace. A carbon-containing gas, known as the carbon source or precursor, is passed through the furnace.

At a high temperature, the gas decomposes, releasing carbon atoms. These atoms then diffuse toward a substrate that is coated with a metallic catalyst.

The Role of the Catalyst

The catalyst, typically a nanoparticle of a transition metal like iron, nickel, or cobalt, is the seed for nanotube growth. The carbon atoms land on the catalyst particle and assemble themselves into the hexagonal lattice structure of a carbon nanotube, which then grows outward from the catalyst.

Why CVD is the Standard

CVD is the most commonly employed technique for synthesizing nanomaterials for a clear reason. It provides an effective pathway to produce high-quality materials by allowing for precise control over the final product's properties.

The Critical Parameters That Define Success

The quality, length, and diameter of the carbon nanotubes are not accidental. They are the direct result of carefully managing several key operating parameters during the CVD process.

Choice of Carbon Source

The gas used as the carbon feedstock significantly impacts the energy required for the process.

Common sources like methane and ethylene must first be thermally broken down to form the direct carbon precursors for growth. In contrast, acetylene can act as a direct precursor without this extra energy input.

This means acetylene is more energy-efficient for CNT synthesis, followed by ethylene, and then methane, which requires the most energy for thermal conversion.

Reaction Temperature

Temperature is the engine of the CVD process. It provides the necessary energy to break the chemical bonds in the carbon source gas, releasing the carbon atoms required for nanotube formation. The specific temperature range depends heavily on the catalyst and carbon source being used.

Gas Residence Time

Residence time is the duration the carbon source gas spends in the high-temperature reaction zone. This parameter is a delicate balancing act.

An optimal residence time ensures a high growth rate. Too little time, and the gas passes through without fully decomposing, wasting material. Too much time, and by-products can accumulate, limiting the supply of fresh carbon source to the catalyst and hindering growth.

Understanding the Trade-offs and Challenges

While powerful, the CVD method is not without its complexities. Achieving high-quality output requires navigating several key trade-offs.

Purity vs. Yield

One of the primary challenges is producing a high yield of nanotubes without also creating unwanted by-products, such as amorphous carbon. Optimizing conditions for high yield can sometimes compromise the structural purity of the final product.

The Balancing Act of Residence Time

As noted, managing residence time is critical. An engineer must find the precise sweet spot for a given system. Insufficient time wastes the carbon source, while excessive time poisons the reaction environment with by-products and limits catalyst effectiveness.

Cost vs. Quality

The choice of carbon source directly impacts both cost and quality. While more reactive gases like acetylene are more energy-efficient, they can also be more expensive. Methane is often cheaper but requires higher temperatures and more energy to achieve the same result.

Making the Right Choice for Your Goal

The ideal approach to carbon nanotube synthesis depends entirely on the intended application. Understanding the parameters of the CVD process allows you to tailor the output to meet specific needs.

- If your primary focus is high-volume, cost-effective production: Using a lower-cost precursor like methane in a well-optimized, continuous CVD system is the standard industrial approach.

- If your primary focus is high-purity, structurally perfect nanotubes for research: You would use a highly reactive source like acetylene with a precisely engineered catalyst, focusing on control over yield.

- If your primary focus is sustainable or next-generation synthesis: You would explore emerging methods, such as using waste feedstocks or the pyrolysis of methane.

Ultimately, mastering carbon nanotube synthesis is about precise chemical control to build materials from the atom up.

Summary Table:

| Parameter | Impact on CNT Synthesis |

|---|---|

| Carbon Source | Determines energy efficiency & cost (Acetylene > Ethylene > Methane) |

| Reaction Temperature | Controls energy for gas decomposition and carbon release |

| Gas Residence Time | Balances growth rate vs. by-product formation |

| Catalyst Choice | Seeds nanotube growth and defines structure (Fe, Ni, Co) |

Ready to achieve precise control over your carbon nanotube synthesis? KINTEK specializes in providing advanced lab equipment and consumables, including CVD systems tailored for nanomaterial research and production. Whether your goal is high-volume manufacturing or high-purity research, our expertise can help you optimize every parameter for superior results. Contact our experts today to discuss how we can support your laboratory's specific needs in nanotechnology and advanced materials development.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Multi Heating Zones CVD Tube Furnace Machine Chemical Vapor Deposition Chamber System Equipment

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

People Also Ask

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition