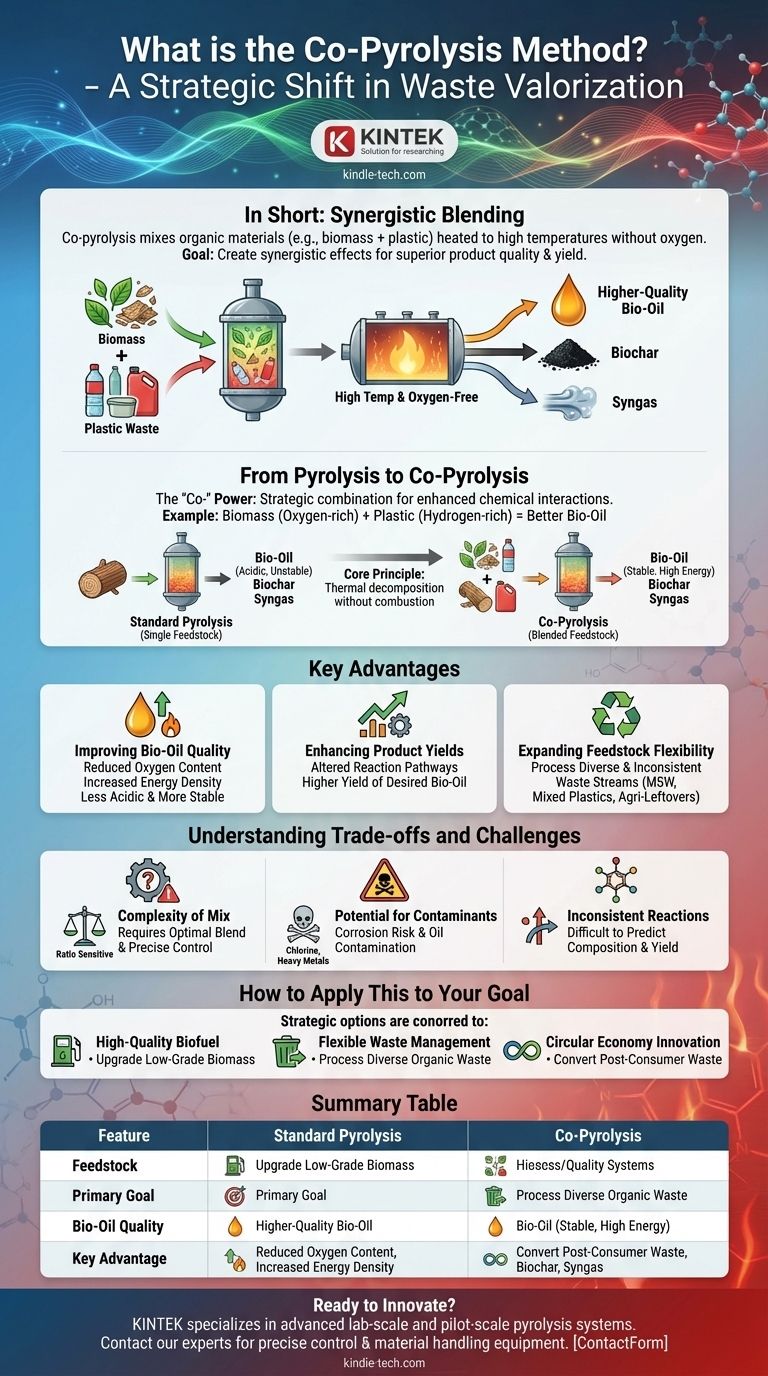

In short, co-pyrolysis is a thermochemical process where a mixture of two or more different types of organic materials are heated to high temperatures in an oxygen-free environment. Unlike standard pyrolysis which processes a single type of feedstock, co-pyrolysis deliberately blends different materials—such as biomass with plastic waste—to create synergistic effects and improve the quality and yield of the final products.

The core value of co-pyrolysis is not simply mixing waste, but strategically combining feedstocks to overcome the limitations of pyrolyzing them individually. This synergy often results in a higher-quality liquid fuel (bio-oil) and provides a more flexible solution for waste valorization.

From Pyrolysis to Co-Pyrolysis: A Fundamental Shift

To understand co-pyrolysis, we must first be clear on the baseline process of pyrolysis. This provides the context for why adding the "co-" prefix represents a significant strategic evolution.

Revisiting Pyrolysis: The Core Principle

Pyrolysis is the thermal decomposition of carbon-based materials at elevated temperatures (typically 400-800°C) in the complete or near-complete absence of oxygen.

Without oxygen, the material doesn't combust. Instead, its chemical bonds break apart, converting a solid feedstock into three primary products: a liquid (known as bio-oil or pyrolysis oil), a solid (known as biochar), and a gas (known as syngas).

Introducing the "Co-": The Power of Combination

Co-pyrolysis applies this same principle to a blended feedstock. The entire process, from shredding and drying to the reactor stage, is designed to handle a mixture of materials.

A common example is the co-pyrolysis of lignocellulosic biomass (like wood chips or agricultural residue) with waste plastics. The two materials are processed simultaneously in the same reactor.

The Goal: Synergistic Effects

The primary driver for co-pyrolysis is to achieve synergy. The chemical interactions between the different decomposing materials can lead to a final product that is superior to what could be produced from pyrolyzing either material alone.

For instance, biomass is oxygen-rich, while plastics are hydrogen-rich. When pyrolyzed together, hydrogen from the decomposing plastic can help stabilize and deoxygenate the compounds from the biomass, creating a more valuable end product.

Key Advantages of Co-Pyrolysis

Blending feedstocks is a deliberate strategy to solve specific chemical and economic challenges inherent in standard pyrolysis, leading to several distinct advantages.

Improving Bio-Oil Quality

Pyrolysis of biomass alone often produces a bio-oil that is acidic, corrosive, viscous, and chemically unstable due to its high oxygen content.

Adding hydrogen-rich plastics to the mix can significantly reduce the oxygen content of the resulting oil. This increases its energy density (calorific value) and makes it less acidic and more stable, bringing its properties closer to those of conventional fossil fuels.

Enhancing Product Yields

The interactive chemistry during co-pyrolysis can alter the reaction pathways. In many cases, this leads to a higher yield of the desired liquid bio-oil and a lower yield of the less desirable biochar or non-condensable gases.

Expanding Feedstock Flexibility

Co-pyrolysis makes a facility more versatile and economically robust. It allows for the processing of a diverse and often inconsistent range of waste streams, such as non-recyclable mixed plastics, municipal solid waste, or agricultural leftovers. This turns multiple low-value waste streams into a viable resource.

Understanding the Trade-offs and Challenges

While powerful, co-pyrolysis is not a simple solution. It introduces complexities that require careful management and advanced process control.

The Complexity of the Feedstock Mix

The results are highly sensitive to the ratio of the materials in the blend. Finding the optimal mix of, for example, biomass to polyethylene to achieve the desired oil quality requires significant research, development, and precise process control. An incorrect ratio can negate the benefits.

Potential for Contaminants

Mixing feedstocks, particularly from waste streams, increases the risk of introducing contaminants. Chlorine from PVC plastics, for example, can form hydrochloric acid, which corrodes equipment and contaminates the oil. Other plastics can introduce heavy metals or other harmful additives.

Inconsistent and Complex Reactions

The chemical interactions between different materials during decomposition are extremely complex and not always fully understood. This can make it difficult to consistently predict product composition and yield, especially when scaling the process from the laboratory to an industrial plant.

How to Apply This to Your Goal

Your decision to use co-pyrolysis should be driven by a specific objective. The process is a strategic tool, not a one-size-fits-all solution for waste.

- If your primary focus is high-quality biofuel production: Use co-pyrolysis to upgrade low-grade biomass by blending it with hydrogen-rich waste plastics, aiming for a stable, energy-dense liquid fuel.

- If your primary focus is flexible waste management: Employ co-pyrolysis to create a robust system capable of processing diverse and mixed organic waste streams that are otherwise destined for landfill.

- If your primary focus is circular economy innovation: View co-pyrolysis as a key technology for converting complex, low-value post-consumer waste into valuable chemical feedstocks for new materials.

Ultimately, co-pyrolysis transforms the challenge of feedstock limitations into an opportunity for chemical optimization.

Summary Table:

| Feature | Standard Pyrolysis | Co-Pyrolysis |

|---|---|---|

| Feedstock | Single material (e.g., biomass) | Mixture of materials (e.g., biomass + plastic) |

| Primary Goal | Decompose feedstock into oil, char, and gas | Achieve synergy to improve product quality/yield |

| Bio-Oil Quality | Often acidic, unstable, high oxygen | More stable, less acidic, higher energy density |

| Key Advantage | Simplicity | Feedstock flexibility and product upgrading |

Ready to innovate your waste valorization or biofuel production process? The strategic application of co-pyrolysis requires precise control and the right equipment. KINTEK specializes in advanced lab-scale and pilot-scale pyrolysis systems, providing the reliable tools you need to research and develop your co-pyrolysis applications. Our reactors are designed for the precise temperature control and material handling necessary to explore synergistic effects and optimize your feedstock blends. Contact our experts today to discuss how our equipment can help you achieve your specific goals in renewable energy and circular economy innovation.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory Test Sieves and Sieving Machines

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

People Also Ask

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs