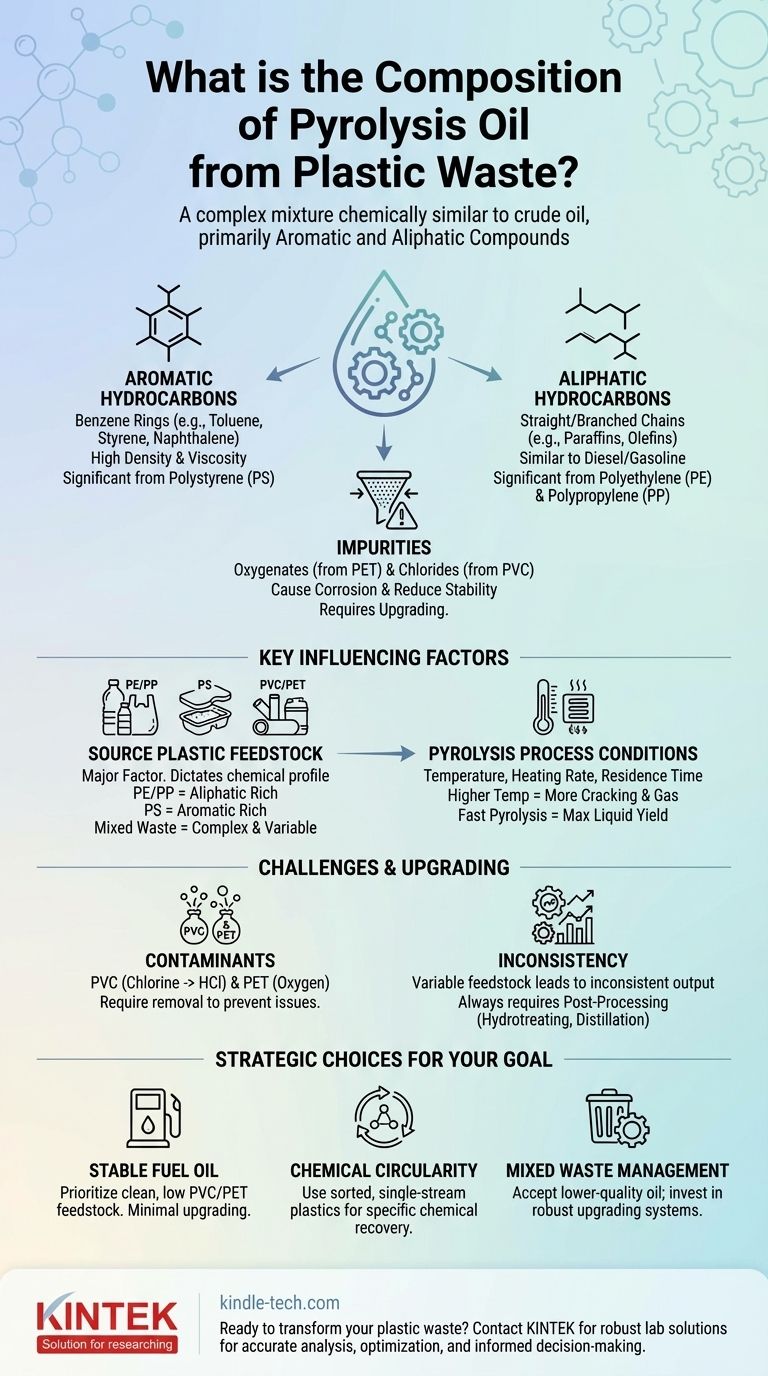

At its core, pyrolysis oil derived from plastic waste is a complex liquid mixture of hydrocarbons, chemically similar to crude oil but with its own distinct characteristics. Its composition is primarily a blend of aromatic and aliphatic compounds, with the exact ratio and presence of other chemicals being highly variable. This variability is the central challenge and opportunity in its use.

The single most important takeaway is that there is no single, fixed composition for plastic pyrolysis oil. Its chemical makeup is a direct reflection of two critical variables: the specific types of plastic in the feedstock and the precise conditions of the pyrolysis process.

Deconstructing the Chemical Profile

To understand the value and challenges of pyrolysis oil, we must first break down its primary components. This liquid is a synthetic crude oil, formed by the thermal decomposition of long polymer chains in an oxygen-free environment.

The Dominance of Aromatics

Aromatic hydrocarbons are compounds containing one or more benzene rings. Think of substances like toluene, xylene, and naphthalene.

Their high concentration in pyrolysis oil is a result of the intense thermal cracking and subsequent recombination of plastic molecules during the process. A high aromatic content influences the oil's density, viscosity, and combustion properties.

The Role of Aliphatics

Aliphatic hydrocarbons are straight-chain, branched, or cyclic compounds without benzene rings, including paraffins and olefins. These are more akin to the components found in conventional diesel and gasoline.

The presence of these compounds is often directly linked to the original structure of the input plastics, such as polyethylene and polypropylene, which are fundamentally long aliphatic chains.

Other Significant Compounds

Beyond these two major groups, other compounds are often present, typically as impurities. These can include oxygenates (from plastics like PET) and chlorinated compounds (from PVC). These substances are critical to identify as they can cause corrosion and environmental issues if not managed.

Key Factors Influencing Composition

The final chemical makeup of the oil is not accidental. It is dictated by deliberate operational choices and the nature of the raw material being processed.

The Source Plastic Feedstock

This is the most significant factor. Different plastics are made of different chemical building blocks, and their decomposition products reflect that.

Plastics like polyethylene (PE) and polypropylene (PP) will yield an oil rich in aliphatic compounds. In contrast, polystyrene (PS) will produce an oil with a very high concentration of aromatics, including its base monomer, styrene.

Pyrolysis Process Conditions

The method of heating determines how the polymer chains break apart. Key parameters include:

- Temperature: Higher temperatures often lead to more cracking, producing lighter hydrocarbons and more gas.

- Heating Rate: A fast pyrolysis (rapid heating) tends to maximize liquid oil yield.

- Residence Time: The duration the material spends at high temperature influences the extent of secondary cracking reactions.

Understanding the Trade-offs and Impurities

While pyrolysis presents a powerful recycling solution, its output is not a perfect, ready-to-use product. Understanding its limitations is crucial for successful implementation.

The Challenge of Contaminants

Using mixed plastic waste, such as post-consumer packaging or municipal solid waste, introduces significant challenges.

The presence of PVC plastic is a major concern, as it releases chlorine that can form highly corrosive hydrochloric acid (HCl) during the process. Similarly, PET introduces oxygen into the oil, reducing its stability and energy value.

Inconsistency and Upgrading Needs

The variable nature of plastic waste streams means the output oil's composition can change from one batch to the next.

This inconsistency means that pyrolysis oil almost always requires significant post-processing or upgrading—such as hydrotreating to remove contaminants or distillation to separate it into useful fractions—before it can be used as a fuel or a chemical feedstock.

Making the Right Choice for Your Goal

The "best" pyrolysis oil composition depends entirely on the intended application. Your operational strategy should be tailored to your end goal.

- If your primary focus is producing a stable fuel oil: You must prioritize a clean feedstock low in PVC and PET to create an oil that requires minimal upgrading.

- If your primary focus is chemical circularity: You need to use sorted, single-stream plastics (like pure polystyrene or polyethylene) to recover specific, high-value chemical monomers.

- If your primary focus is managing mixed municipal waste: You must accept a lower-quality oil and invest in robust upgrading and purification systems to create a commercially viable product.

Ultimately, mastering the relationship between input plastic, process conditions, and output composition is the key to unlocking the true potential of chemical recycling.

Summary Table:

| Component | Description | Influence on Oil |

|---|---|---|

| Aromatic Hydrocarbons | Compounds with benzene rings (e.g., toluene, styrene). | High density, viscosity; significant from PS plastic. |

| Aliphatic Hydrocarbons | Straight or branched chains (e.g., paraffins, olefins). | Similar to diesel/gasoline; significant from PE/PP plastics. |

| Impurities (Oxygenates, Chlorides) | From plastics like PET (oxygen) and PVC (chlorine). | Can cause corrosion, reduce stability; requires upgrading. |

Ready to transform your plastic waste into valuable resources?

The composition of your pyrolysis oil is key to its value. KINTEK specializes in providing robust laboratory equipment and consumables to help you analyze, optimize, and scale your pyrolysis processes. Whether you're researching feedstock effects, monitoring process conditions, or developing upgrading strategies, our solutions deliver the precision and reliability you need.

We help our laboratory customers achieve:

- Accurate Analysis: Precisely characterize oil composition.

- Process Optimization: Fine-tune temperature and heating rates for desired outputs.

- Informed Decision-Making: Understand the trade-offs between feedstock purity and end-product goals.

Let's build a sustainable future together. Contact our experts today to discuss your specific lab requirements and how KINTEK can support your chemical recycling projects.

Visual Guide

Related Products

- FS Electrochemical Hydrogen Fuel Cells for Diverse Applications

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Custom PTFE Teflon Parts Manufacturer Adjustable Height Flower Basket

- Custom CVD Diamond Coating for Lab Applications

- Custom PTFE Teflon Parts Manufacturer for Hollow Etching Flower Basket ITO FTO Developing Glue Removal

People Also Ask

- What role does a double-chamber electrochemical permeation cell play in studying hydrogen diffusion in 9% Cr steel?

- What is the function of an H-type exchangeable membrane electrolytic cell? Master Precise Reaction Control

- What is a proton exchange membrane? The Selective Heart of Hydrogen Energy Systems

- What materials are used for the body of a super-sealed electrolytic cell and what are their properties? Select the Right Material for Your Experiment

- What system-level maintenance is important for a proton exchange membrane? Ensure Longevity with Proactive System Care