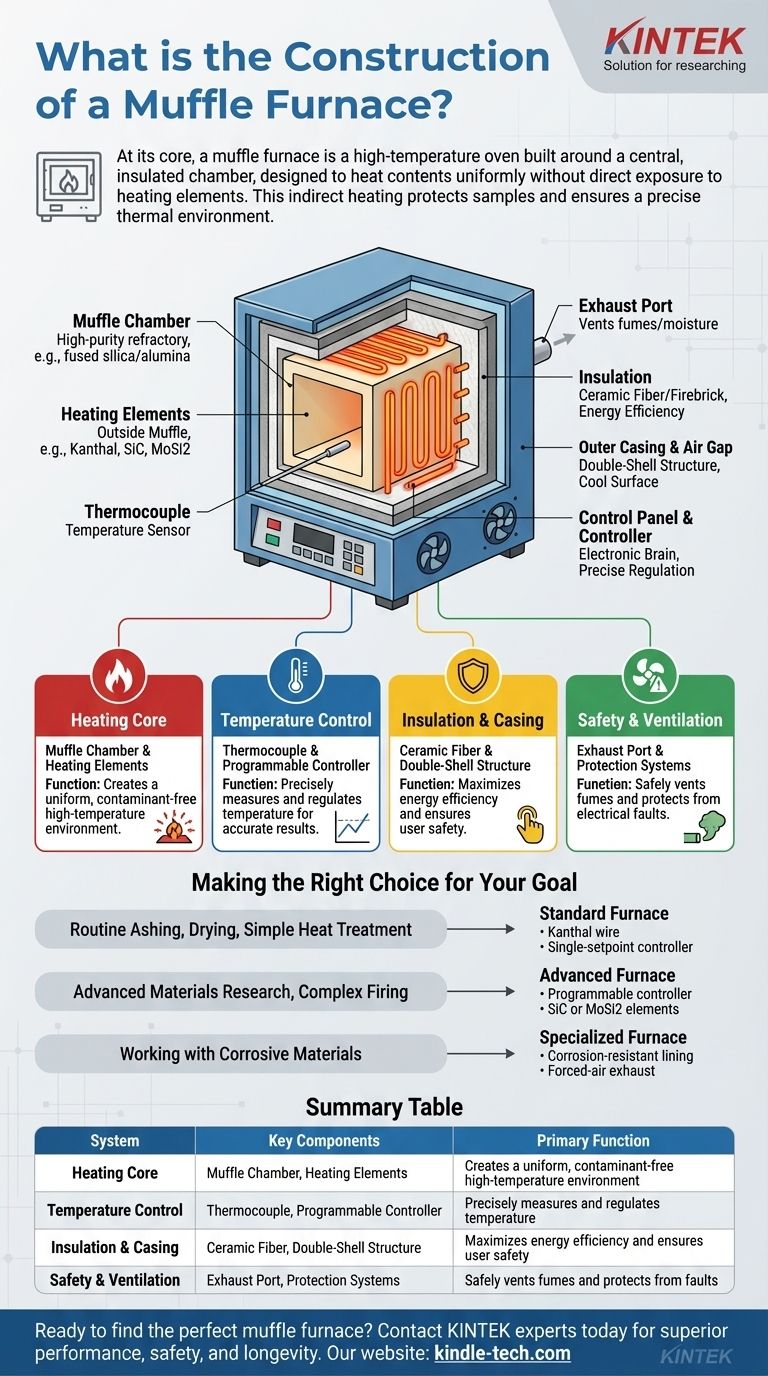

At its core, a muffle furnace is a high-temperature oven built around a central, insulated chamber. This chamber, the "muffle," is designed to heat its contents uniformly without direct exposure to the heating elements. Its construction consists of four primary systems working in concert: the heating core, the temperature control system, the insulation and casing, and an exhaust for ventilation.

The defining characteristic of a muffle furnace's construction is the separation of the sample from the heating source. This indirect heating method protects the sample from contamination and ensures a highly uniform and precisely controlled thermal environment.

The Core Principle: Indirect Heating

The entire design of a muffle furnace revolves around creating a stable, isolated, high-temperature environment. This is achieved by placing the heating elements outside the primary chamber.

The Muffle Chamber

The muffle is the central chamber where samples are placed. It is typically a box made of high-purity refractory materials like fused silica and alumina ceramics.

Its purpose is twofold: to protect the sample from any contaminants produced by the heating elements and to create a uniform radiant heat zone.

The Heating Elements

These are the components that generate the intense heat. They are typically made of high-resistance alloys or materials that can withstand extreme temperatures.

Common materials include iron-chromium-aluminum alloys (often called Kanthal or Kintek wire), silicon carbide (SiC) rods, or molybdenum disilicide (MoSi2) rods for very high temperatures. These elements are strategically placed around the outside of the muffle chamber.

The Insulation

To reach and maintain temperatures often exceeding 1000°C (1832°F), highly effective insulation is critical.

Multiple layers of refractory ceramic fiber or firebrick are packed between the heating elements and the furnace's outer shell. This minimizes heat loss, improves energy efficiency, and keeps the exterior safe to the touch.

The Control and Safety System

A muffle furnace is useless without a system to precisely manage its temperature. This system acts as the furnace's brain and nervous system.

The Thermocouple

This is the temperature sensor. A thermocouple is a probe made of two different metals that generates a tiny voltage proportional to the temperature.

It is carefully placed inside the muffle chamber to get an accurate reading of the internal environment. It is crucial that operators do not damage or disturb this sensitive component when loading samples.

The Temperature Controller

The controller is the electronic brain of the furnace. It continuously reads the voltage from the thermocouple, converts it into a temperature reading, and compares it to the desired setpoint.

Based on this comparison, it switches power on or off to the heating elements via solid-state relays, ensuring the target temperature is maintained with high precision. Modern furnaces feature programmable controllers that can execute complex heating cycles with specific ramp rates and dwell times.

Safety and Power Features

New-generation furnaces incorporate critical safety mechanisms directly into their construction. These include systems for over-current, over-voltage, and leakage protection to ensure safe operation.

Structural and Ancillary Components

These parts provide the physical structure, user interface, and safety for the entire apparatus.

The Outer Casing

The outer shell provides structural integrity and protects the user from the extreme internal temperatures. It is typically made of robust powder-coated steel or aluminum.

Many modern designs use a double-shell structure with a fan-cooled air gap between the inner and outer layers. This keeps the external surface temperature low even when the furnace is at its maximum operating temperature.

The Exhaust Port

Many chemical and material processes release gases, fumes, or moisture when heated. An exhaust port, often a small hole at the back or top of the furnace, is essential for safely venting these byproducts from the chamber.

The Control Panel

This is the user interface, which includes the digital temperature controller display and buttons for setting the temperature. It consolidates all operational controls into one accessible location.

Making the Right Choice for Your Goal

Understanding how a muffle furnace is constructed allows you to select the right instrument for your specific application.

- If your primary focus is routine ashing, drying, or simple heat treatment: A standard furnace with a Kanthal wire heating element and a simple, single-setpoint controller is perfectly adequate.

- If your primary focus is advanced materials research or complex firing cycles: You will need a furnace with a multi-segment programmable controller and potentially silicon carbide or molybdenum disilicide elements for higher temperatures.

- If your primary focus is working with materials that release corrosive fumes: A furnace constructed with a corrosion-resistant chamber lining and an integrated, forced-air exhaust system is non-negotiable for safety and longevity.

Ultimately, the construction of a muffle furnace is a direct reflection of its intended purpose, balancing performance, safety, and precision.

Summary Table:

| System | Key Components | Primary Function |

|---|---|---|

| Heating Core | Muffle Chamber, Heating Elements | Creates a uniform, contaminant-free high-temperature environment |

| Temperature Control | Thermocouple, Programmable Controller | Precisely measures and regulates temperature for accurate results |

| Insulation & Casing | Ceramic Fiber, Double-Shell Structure | Maximizes energy efficiency and ensures user safety |

| Safety & Ventilation | Exhaust Port, Over-Current Protection | Safely vents fumes and protects the equipment from electrical faults |

Ready to find the perfect muffle furnace for your specific application?

Whether your lab's primary focus is routine ashing, advanced materials research, or processing corrosive materials, KINTEK has the expertise and equipment to meet your needs. Our range of muffle furnaces is built with the precise construction details outlined above, ensuring superior performance, safety, and longevity.

Contact our lab equipment experts today to discuss your thermal processing requirements and discover how KINTEK's solutions can enhance your laboratory's efficiency and results.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the temperature of furnace exhaust? A Key Indicator of Efficiency and Safety

- What are the advantages and limitations of heat treatment? Tailor Material Properties for Peak Performance

- How do you run a muffle furnace? Master the Step-by-Step Process for Safe, Precise Results

- How do you keep a sample in a muffle furnace? A Guide to Safe and Accurate Placement

- What is the melting temperature of ceramics? Understanding High-Temperature Material Performance