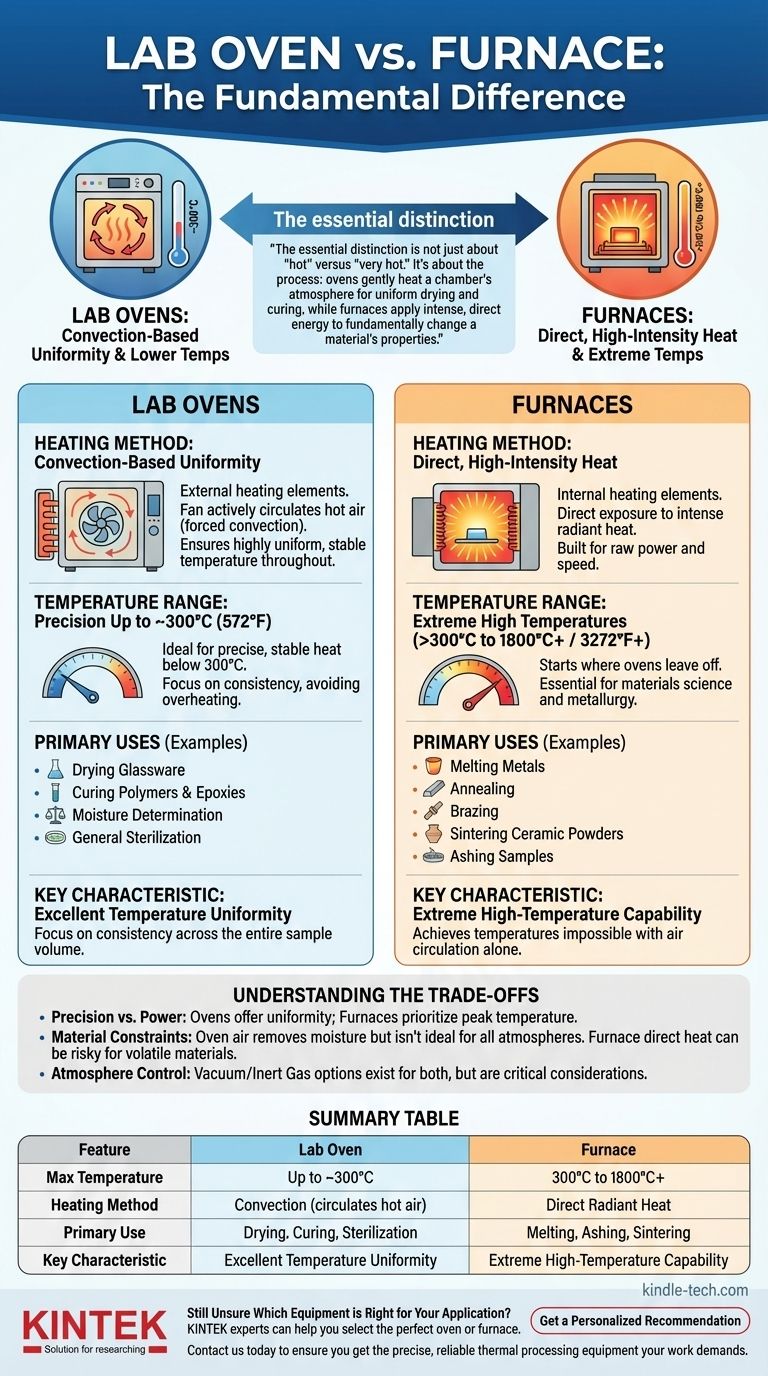

At its core, the difference between a lab oven and a furnace comes down to maximum temperature and the method of heating. Ovens typically operate at lower temperatures (up to around 300°C) and use convection to circulate hot air for uniform heating, while furnaces reach much higher temperatures (often well over 1000°C) by directly radiating heat onto the sample.

The essential distinction is not just about "hot" versus "very hot." It's about the process: ovens gently heat a chamber's atmosphere for uniform drying and curing, while furnaces apply intense, direct energy to fundamentally change a material's properties.

The Fundamental Difference: How Heat is Delivered

The method used to generate and transfer heat dictates the equipment's primary function and capabilities. These two approaches serve entirely different scientific and industrial purposes.

Lab Ovens: Convection-Based Uniformity

A lab oven functions much like a high-precision kitchen convection oven. The heating elements are located outside the main chamber.

A fan then actively circulates the heated air throughout the chamber. This process, called forced convection, ensures that all items inside experience a highly uniform and stable temperature.

Furnaces: Direct, High-Intensity Heat

In a furnace, the heating elements are typically inside the chamber, directly exposing the sample to intense radiant heat.

This direct-heating approach is designed for raw power and speed, allowing the furnace to reach extreme temperatures that would be impossible with air circulation alone. The goal is to drive energy directly into the material itself.

Temperature Range and Its Implications

The temperature capability is the most obvious differentiator and directly correlates with the intended application.

Ovens: Precision in Lower Ranges (Up to ~300°C)

Ovens excel at processes that require precise, stable, and uniform heat below approximately 300°C (572°F).

Their design is ideal for applications like drying glassware, curing polymers and epoxies, moisture determination, and general sterilization. The focus is on consistency across the entire sample volume without overheating.

Furnaces: Reaching Extreme Temperatures (Above 300°C to 1800°C+)

Furnaces are built for high-temperature work, starting where ovens leave off and extending to 1800°C (3272°F) or higher.

This capability is essential for applications in metallurgy, ceramics, and materials science. Common uses include melting metals, annealing, brazing, sintering ceramic powders, and ashing samples to determine inorganic content.

Understanding the Trade-offs

Choosing between an oven and a furnace involves evaluating the compromises inherent in each design. There is no single "better" instrument; there is only the right tool for the job.

The Precision vs. Power Dilemma

Lab ovens provide exceptional temperature uniformity across a large internal volume, but are limited in their peak temperature.

Furnaces prioritize reaching the highest possible temperatures. While modern furnaces have excellent controllers, achieving perfect uniformity can be more challenging than in a convection oven, especially with complex sample geometries.

Material and Process Constraints

The circulating air in an oven is perfect for removing moisture but can be undesirable if a sample needs to be processed in a specific atmosphere.

Conversely, the exposed, high-temperature heating elements in many furnaces can create a risk if processing materials that release volatile or flammable components.

Atmosphere Control

Specialized lab ovens, often called vacuum ovens, are designed to operate under a vacuum or be backfilled with an inert gas like nitrogen or argon. This is critical for preventing oxidation during sensitive curing or annealing processes.

Furnaces can also be configured with atmosphere control, but it is a fundamental design consideration. Choosing the right equipment requires knowing if your process must occur in ambient air, an inert atmosphere, or a vacuum.

Making the Right Choice for Your Application

Selecting the correct thermal processing unit requires a clear understanding of your material, your process, and your desired outcome.

- If your primary focus is drying, sterilizing, or low-temperature curing (<300°C): A convection lab oven is the correct tool for its temperature uniformity and gentle heating.

- If your primary focus is melting, ashing, or materials testing at high temperatures (>300°C): A furnace is necessary to achieve the required thermal energy.

- If your primary focus is preventing oxidation (e.g., annealing, brazing): You must select a specialized vacuum oven or a controlled-atmosphere furnace, depending on your target temperature.

Ultimately, matching the heating method and temperature range to your specific application is the key to achieving reliable and repeatable results.

Summary Table:

| Feature | Lab Oven | Furnace |

|---|---|---|

| Max Temperature | Up to ~300°C | 300°C to 1800°C+ |

| Heating Method | Convection (circulates hot air) | Direct Radiant Heat |

| Primary Use | Drying, Curing, Sterilization | Melting, Ashing, Sintering |

| Key Characteristic | Excellent Temperature Uniformity | Extreme High-Temperature Capability |

Still Unsure Which Equipment is Right for Your Application?

KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you select the perfect oven or furnace based on your specific temperature requirements, process goals, and material constraints. Contact us today to ensure you get the precise, reliable thermal processing equipment your work demands.

Get a Personalized Recommendation

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How does heat affect material strength? Understanding Thermal Degradation and Creep Failure

- What are the factors that affect melting? Master Temperature, Pressure & Chemistry for High-Quality Results

- What is the capacity of a muffle furnace? Find the Right Size for Your Lab Needs

- Can a muffle furnace be used for calcination? Achieve Pure, Controlled Thermal Decomposition

- What is a muffle furnace? The Definitive Tool for Contaminant-Free, Precise Heating