At a fundamental level, the difference between a pneumatic and a hydraulic press is the medium used to generate force. Pneumatic presses use compressed air—a compressible gas—to move a piston. Hydraulic presses use pressurized fluid—typically an incompressible oil—to achieve the same goal. This single difference in the force medium dictates their vastly different capabilities in speed, power, and precision.

The choice isn't about which press is superior, but which is the correct tool for the job. Pneumatic presses are masters of speed and repetition for lower-force tasks, while hydraulic presses deliver immense, controllable power for heavy-duty applications.

The Core Principle: How They Generate Force

To understand the practical differences, you must first understand their mechanisms. The physics of a gas versus a liquid is the source of all their respective strengths and weaknesses.

Pneumatic Presses: The Power of Compressed Air

A pneumatic press relies on an air compressor to pressurize and store air. When activated, valves release this compressed air into a cylinder, pushing a piston down with rapid force.

Because air is a compressible gas, the force is delivered like a quick punch. The system is mechanically simple, fast, and relies on readily available shop air.

Hydraulic Presses: The Strength of Incompressible Fluid

A hydraulic press uses a pump to pressurize a liquid, almost always oil, within a closed system. This pressure is then applied to a piston, multiplying the force according to Pascal's principle.

Since the oil is incompressible, the force is delivered smoothly and is constant throughout the entire press stroke. This allows for tremendous force generation and precise control over the pressure being applied.

Comparing Key Performance Metrics

The choice between pneumatic and hydraulic becomes clear when you compare them across the factors that matter most in an industrial setting.

Force (Tonnage)

Pneumatic presses operate at much lower pressures, typically around 100 psi. This limits their force output to a range of a few hundred pounds up to a few tons, making them ideal for lighter work.

Hydraulic presses can operate at pressures of 1,000 to 3,000 psi or more. This allows them to generate immense force, easily reaching hundreds or even thousands of tons for the most demanding jobs.

Speed and Cycle Rate

Pneumatic systems are built for speed. Air can be compressed and exhausted very quickly, allowing for extremely high cycle rates. This makes them perfect for high-volume, repetitive tasks like punching or light assembly.

Hydraulic systems are inherently slower. Moving a dense, viscous fluid takes more time than moving air. Their cycle rates are significantly lower, prioritizing raw power over repetition speed.

Precision and Control

The compressibility of air makes it difficult for a pneumatic press to maintain a precise, consistent force throughout its stroke. They are better suited for tasks requiring a quick application of force.

The incompressibility of hydraulic fluid gives these presses unparalleled control. They can apply and hold an exact tonnage at any point in the stroke, which is critical for operations like deep drawing, molding, or precision forming.

Understanding the Practical Trade-offs

Beyond raw performance, the day-to-day realities of cost, maintenance, and operation also play a critical role in the decision.

Cost and Complexity

Pneumatic systems are generally less expensive to purchase and install. The components are simpler, more standardized, and do not need to withstand the extreme pressures of a hydraulic system.

Hydraulic systems have a higher initial cost. The pumps, high-pressure hoses, reservoirs, and precision valves required for operation are more complex and expensive to manufacture.

Maintenance and Cleanliness

Pneumatic presses are cleaner to operate. While air leaks can be a source of inefficiency, they do not contaminate the workspace. Maintenance is often simpler.

Hydraulic presses are susceptible to fluid leaks. A leaking hose or fitting can create significant safety hazards and cleanup challenges. Maintenance requires specialized knowledge of hydraulic systems.

Energy Consumption

Air compressors often run continuously to keep a reservoir pressurized, which can be energy-intensive. However, the press itself only consumes that energy when cycling.

Hydraulic pumps typically only run when the press is in motion, making them potentially more energy-efficient for applications with long dwell times or infrequent cycles.

Making the Right Choice for Your Application

The ideal press is determined entirely by the demands of your task. Use these guidelines to steer your decision.

- If your primary focus is speed and high-volume production for light tasks: A pneumatic press is the superior choice for assembly, light stamping, or punching.

- If your primary focus is immense force and precision control: A hydraulic press is the industry standard for deep drawing, forging, molding, and heavy-duty forming.

- If your primary focus is cleanliness and a lower initial cost for a lower-force job: A pneumatic system offers a cleaner work environment and a more accessible entry point.

Ultimately, choosing between these systems is a matter of matching the unique properties of a compressible gas versus an incompressible fluid to your specific operational needs.

Summary Table:

| Feature | Pneumatic Press | Hydraulic Press |

|---|---|---|

| Force Medium | Compressed Air (Gas) | Hydraulic Fluid (Oil) |

| Max Force (Tonnage) | Low (Up to a few tons) | High (Hundreds to thousands of tons) |

| Speed & Cycle Rate | Very Fast | Slower |

| Precision & Control | Lower | High (Can hold precise pressure) |

| Ideal For | High-volume, light tasks (assembly, punching) | Heavy-duty forming (forging, molding, deep drawing) |

| Initial Cost | Lower | Higher |

| Cleanliness | Cleaner (air leaks) | Risk of fluid leaks |

Still unsure which press is right for your laboratory or production line? The experts at KINTEK are here to help. We specialize in providing the perfect lab equipment solutions—from high-speed pneumatic presses for repetitive tasks to powerful hydraulic presses for demanding applications.

Let us help you optimize your process. Contact our team today for a personalized consultation and discover how the right press can enhance your efficiency, precision, and results.

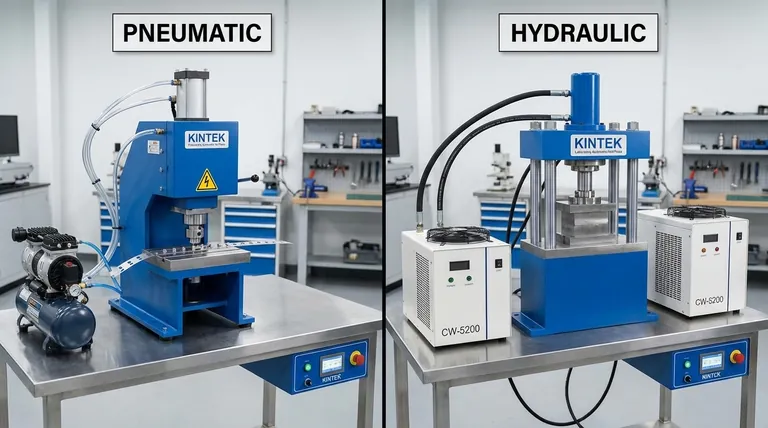

Visual Guide

Related Products

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- Can a hydraulic press break a diamond? Yes, and here’s why hardness isn't strength.

- What is the BARS apparatus and what is its basic structure? Discover Compact High-Pressure Diamond Synthesis

- What role does a laboratory hydraulic press play in LGPS electrolyte fabrication? Master Cold-Pressing for SSBs

- What is the primary function of a powder pellet press in the preparation of fillers? Achieve Superior Ceramic Joining

- How does a laboratory hydraulic press assist in XAS sample quality? Precision Pellets for Superior Spectral Clarity

- What are the maintenance required for the hydraulic system? A Proactive Guide to Prevent Costly Failures

- Can a hydraulic press press anything? Understanding the Real Limits of Its Power

- Why is a laboratory hydraulic press essential for solid-state batteries? Achieve Peak Ionic Conductivity