At their core, the primary difference between ASTM and IS standard sieves lies in the governing bodies that create and maintain their specifications. ASTM sieves conform to standards set by ASTM International (an American organization), while IS sieves adhere to standards published by the Bureau of Indian Standards (BIS). Although both are based on international principles and are very similar, their specific lists of standard sieve sizes and designations are not identical.

The critical takeaway is that while both ASTM and IS sieves are built for the same purpose and are largely harmonized with international ISO standards, they are not directly interchangeable for work requiring strict regulatory or contractual compliance. The specific standard cited in your project documentation dictates which type of sieve you must use.

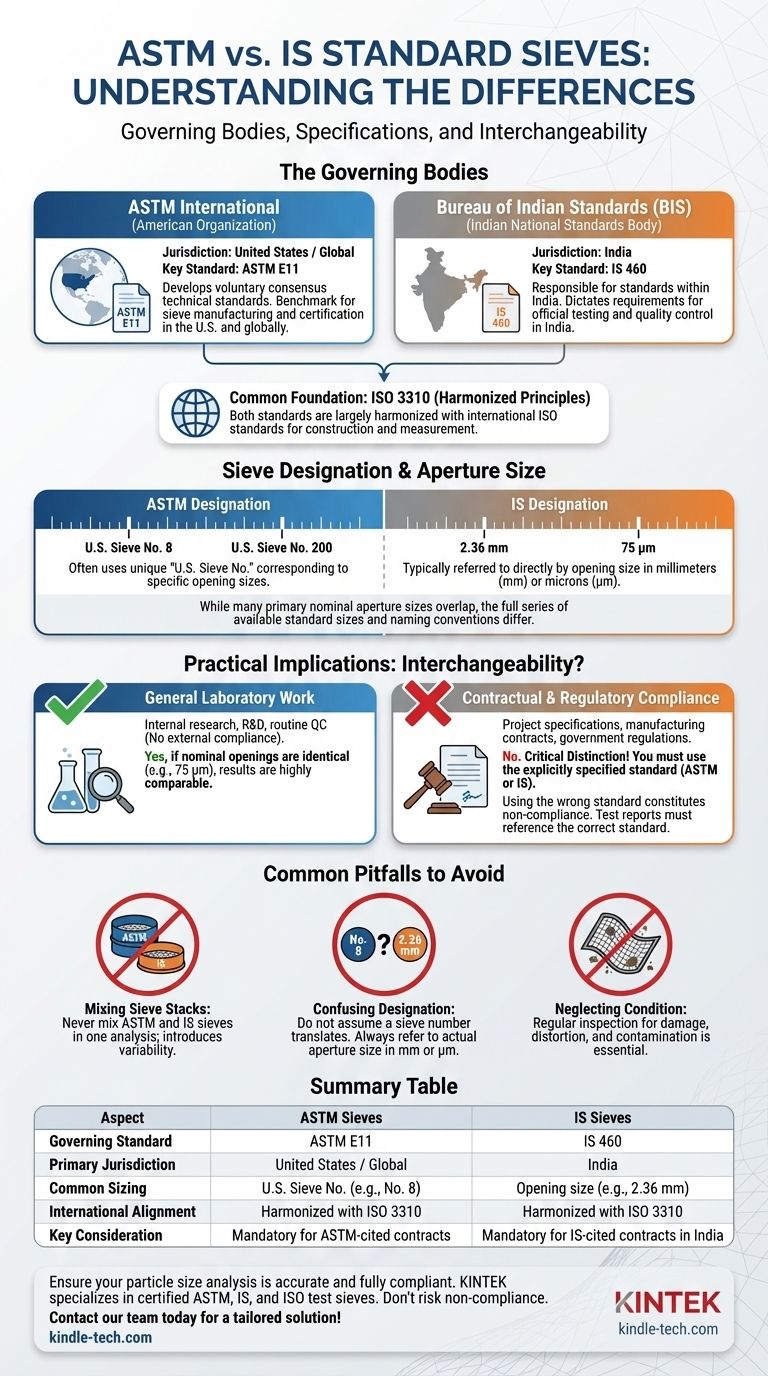

The Governing Bodies Behind the Standards

To understand the differences, you must first understand the organizations that define them. Each standard serves a specific jurisdiction and is maintained by a separate entity.

ASTM International

ASTM International, formerly the American Society for Testing and Materials, is a global organization that develops and publishes voluntary consensus technical standards.

The key standard for test sieves is ASTM E11, "Standard Specification for Woven Wire Test Sieve Cloth and Test Sieves." This is the benchmark for sieve manufacturing and certification in the United States and many other parts of the world.

Bureau of Indian Standards (IS)

The Bureau of Indian Standards (BIS) is the National Standards Body of India. It is responsible for the development and promotion of standards for products and systems within the country.

The relevant standard for test sieves in India is IS 460, "Specification for Test Sieves." This standard dictates the requirements for sieves used for official testing and quality control within India.

Comparing the Core Specifications

While governed by different bodies, the technical specifications share a common foundation, which explains their similarities. The differences, though minor, are important.

The Foundation: ISO 3310

Both ASTM E11 and IS 460 are largely harmonized with the international standard ISO 3310-1, "Test sieves — Technical requirements and testing."

This common root means that the fundamental principles of construction, such as the quality of the wire cloth and the method of measuring aperture size, are nearly identical.

Sieve Designation and Aperture Size

This is where the most noticeable practical difference arises. Both standards define a series of preferred nominal aperture sizes (the size of the openings in the mesh).

While many of the primary sizes overlap perfectly (e.g., 1.00 mm, 2.00 mm), the full series of available standard sizes can differ slightly. One standard may include an intermediate sieve size that the other does not.

Furthermore, ASTM sieves are often referred to by a "U.S. Sieve No." (e.g., No. 8, No. 200), which corresponds to a specific opening size. This numbering system is unique to the ASTM standard. IS sieves are typically referred to directly by their opening size in millimeters (mm) or microns (µm).

The Practical Implications: Are They Interchangeable?

The answer depends entirely on the context of your work.

For General Laboratory Work

For internal research, product development, or routine quality checks where there are no external compliance requirements, sieves from either standard can often be used effectively.

If an ASTM sieve and an IS sieve have the exact same nominal opening (e.g., 75 µm), they will produce highly comparable results for particle size analysis.

For Contractual and Regulatory Compliance

This is where the distinction is critical. If a project specification, manufacturing contract, or government regulation explicitly requires testing "in accordance with ASTM E11," you must use ASTM E11 certified sieves.

Using an IS 460 sieve, even one with an identical nominal opening, would constitute non-compliance. The test report must reference the correct standard, which requires using equipment certified to that standard.

Certification and Traceability

Every compliant test sieve, whether ASTM or IS, is sold with a certificate of compliance. This document provides traceability and confirms that the sieve's manufacturing tolerances (for wire diameter, aperture size, etc.) meet the specific requirements of the designated standard.

Common Pitfalls to Avoid

Mistakes in sieve selection can invalidate your test results, leading to costly project delays or quality control failures.

Mixing Sieve Stacks

Never mix ASTM and IS sieves within a single sieve stack for one analysis. This introduces variability and complicates the proper reporting of results, especially if the nominal sizes are not a perfect match across the stack.

Confusing Designation with Size

Do not assume a sieve number from one standard translates to another. A "No. 8" ASTM sieve has a 2.36 mm opening. There is no equivalent "No. 8" in the IS system; you would simply look for a 2.36 mm IS sieve. Always refer to the actual aperture size in mm or µm.

Neglecting Sieve Condition

Regardless of the standard, the sieve's accuracy is only guaranteed if it is in good condition. Regular inspection for damage, distortion (sagging), and contamination, along with periodic re-calibration, is essential for reliable results.

Making the Right Choice for Your Project

Your choice should be guided by your specific objective and operating requirements.

- If your primary focus is regulatory or contractual compliance: Use only the sieve standard (ASTM E11 or IS 460) explicitly cited in your project documents.

- If your primary focus is internal R&D or routine QC: You may use sieves from either standard, but ensure consistency by using the same type for a given test protocol to maintain comparability.

- If your primary focus is global collaboration: It is often best to standardize on the ISO 3310 series, as it serves as the international foundation from which both ASTM and IS standards are derived.

Understanding these distinctions ensures your particle size analysis is not only accurate but also compliant and defensible.

Summary Table:

| Aspect | ASTM Sieves | IS Sieves |

|---|---|---|

| Governing Standard | ASTM E11 | IS 460 |

| Primary Jurisdiction | United States / Global | India |

| Common Sizing Reference | U.S. Sieve No. (e.g., No. 8) | Opening size in mm/µm (e.g., 2.36 mm) |

| International Alignment | Harmonized with ISO 3310 | Harmonized with ISO 3310 |

| Key Consideration | Mandatory for ASTM-cited contracts | Mandatory for IS-cited contracts in India |

Ensure your particle size analysis is accurate and fully compliant. Choosing the right test sieves is critical for meeting regulatory and contractual requirements.

KINTEK specializes in providing high-quality lab equipment and consumables, including a full range of certified ASTM, IS, and ISO test sieves. Our experts can help you select the perfect sieves for your specific application, ensuring traceability and reliability for your laboratory's needs.

Don't risk non-compliance—contact our team today to discuss your sieve requirements and get a tailored solution!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

People Also Ask

- How do high-precision sieving systems benefit zeolite preparation? Maximize Adsorption for Wastewater Treatment

- Why is a laboratory electromagnetic vibratory sieve shaker used? Optimize Walnut Shell Chemical Pretreatment

- Why is a precision vibratory sieving system important for Pt/Pd alloy analysis? Ensure Data Integrity & XRD Accuracy

- What function does a sieving system perform during HPS powder pretreatment? Ensure Uniform Particle Size Distribution

- What is the significance of using a fine sieving system for catalyst particles? Optimize Size for Maximum Reactivity