At its core, the difference between Cold Isostatic Pressing (CIP) and Hot Isostatic Pressing (HIP) comes down to one critical variable: heat. CIP uses only high, uniform pressure at room temperature to compact powders into a solid shape. In contrast, HIP applies both high pressure and high temperature simultaneously to create fully dense materials with superior mechanical properties.

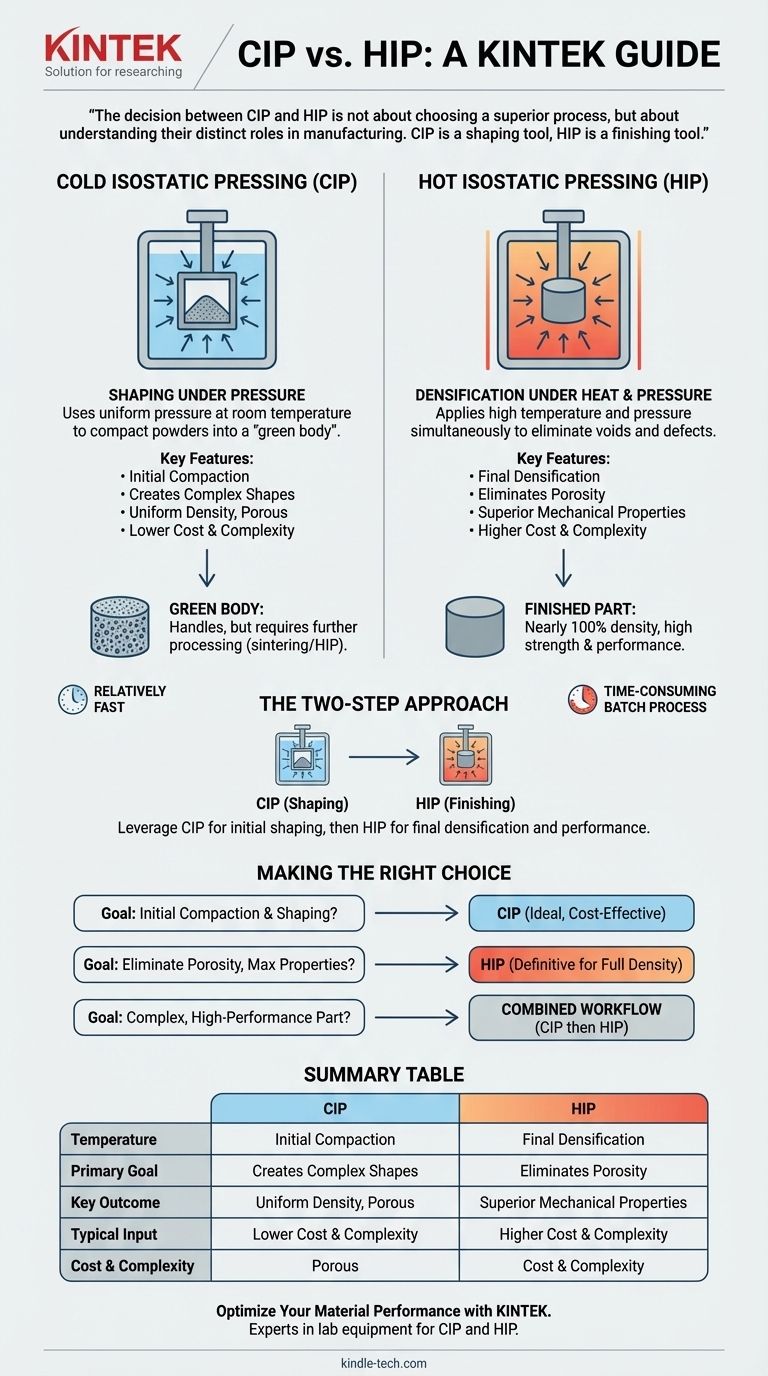

The decision between CIP and HIP is not about choosing a superior process, but about understanding their distinct roles in manufacturing. CIP is a shaping tool for initial compaction, while HIP is a finishing tool for achieving maximum density and performance.

The Fundamental Process Difference: Adding Heat

The names "cold" and "hot" isostatic pressing are quite literal. The addition of thermal energy in the HIP process completely changes its purpose and outcome compared to the cold compaction of CIP.

Cold Isostatic Pressing (CIP): Shaping Under Pressure

CIP involves placing powder in a flexible mold, which is then submerged in a liquid medium. This liquid is pressurized, exerting uniform pressure from all directions onto the mold.

The primary goal of CIP is to compact the powder into a uniformly dense, solid object known as a "green body." This part has enough strength to be handled but is still porous and requires a subsequent thermal process like sintering or HIP to achieve its final properties.

Hot Isostatic Pressing (HIP): Densification Under Heat and Pressure

HIP takes a component—which can be a metal casting, a 3D-printed part, or a "green body" from CIP—and places it inside a high-pressure vessel. The vessel is filled with an inert gas (typically Argon) and is heated to extreme temperatures.

The combination of high heat and uniform gas pressure forces the material's internal voids and porosity to collapse and metallurgically bond. The main goal of HIP is not to shape the part, but to eliminate internal defects and achieve nearly 100% density.

Comparing the Outcomes and Applications

While both processes use isostatic (uniform, all-directional) pressure, their applications and the resulting material characteristics are vastly different.

Material Properties and Performance

Parts produced by CIP are not finished products. They are porous, brittle, and possess low mechanical strength. Their value is in their uniform density, which prevents warping during the subsequent sintering or densification step.

HIP produces materials with vastly improved properties. By eliminating internal porosity, HIP significantly enhances uniformity, ductility, fatigue resistance, and overall mechanical strength, making it essential for high-performance and mission-critical components.

Geometric Complexity

CIP is an excellent method for creating an initial, intricate shape from a powder source. The flexible mold allows for complex geometries to be formed in the "green" state.

HIP is used to densify parts that already have their near-net shape, including those with complex geometries. It is a finishing step for critical components where internal defects cannot be tolerated, regardless of their complexity. Often, a part is first formed using a method like CIP or additive manufacturing, then densified using HIP.

Understanding the Trade-offs

Choosing a process requires a clear understanding of the costs, benefits, and limitations of each method.

Cost and Process Complexity

CIP is a relatively fast and cost-effective process. The equipment operates at room temperature, making it simpler and less energy-intensive.

HIP is a significantly more expensive and time-consuming batch process. The need to safely manage extreme temperatures and high gas pressures requires specialized, capital-intensive equipment and longer cycle times.

The Two-Step Approach

It's common for these processes to be used together. A manufacturer might use CIP to cost-effectively form a complex part from powder, and then use the more expensive HIP process as the final step to achieve the necessary density and performance for a critical application.

This combined approach leverages the strengths of each method: CIP for shaping and HIP for final property enhancement.

Making the Right Choice for Your Goal

Your selection depends entirely on what you need to achieve in your manufacturing workflow.

- If your primary focus is creating a uniform "green body" from powder for subsequent processing: CIP is the ideal, cost-effective choice for initial compaction and shaping.

- If your primary focus is eliminating internal porosity and maximizing the mechanical properties of a finished part: HIP is the definitive process for achieving full density and superior performance.

- If your primary focus is manufacturing a complex, high-performance part from a powder source: Use a combined workflow, starting with CIP to form the shape and finishing with HIP to achieve final specifications.

By understanding their distinct roles, you can leverage CIP for shaping and HIP for final performance to optimize your manufacturing process.

Summary Table:

| Feature | Cold Isostatic Pressing (CIP) | Hot Isostatic Pressing (HIP) |

|---|---|---|

| Temperature | Room Temperature | High Temperature (up to 2000°C+) |

| Primary Goal | Shape powder into a "green body" | Eliminate porosity; achieve near 100% density |

| Key Outcome | Uniform, porous compact for further processing | Fully dense part with superior mechanical properties |

| Typical Input | Powder | Castings, 3D-printed parts, or CIP "green bodies" |

| Cost & Complexity | Lower cost, simpler process | Higher cost, complex batch process |

Optimize Your Material Performance with KINTEK

Choosing between CIP and HIP is critical for achieving the desired density, strength, and geometry in your components. Whether you need an efficient shaping solution or a final densification process for mission-critical parts, KINTEK has the expertise and equipment to support your lab's goals.

We specialize in providing high-quality lab equipment and consumables for all your material processing needs. Let our experts help you select the right press for your application.

Contact KINTEK today to discuss how our isostatic pressing solutions can enhance your manufacturing workflow.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- What are some of the attractive properties of hot isostatic pressed products? Achieve Perfect Density and Superior Performance

- What is HIP in material processing? Achieve Near-Perfect Density for Critical Components

- What are the components of a hot isostatic pressing system? A Guide to Core HIP Equipment

- What is the HIP material process? Achieve Near-Perfect Density and Reliability

- What is HIP treatment for metal? Eliminate Internal Defects for Superior Part Performance