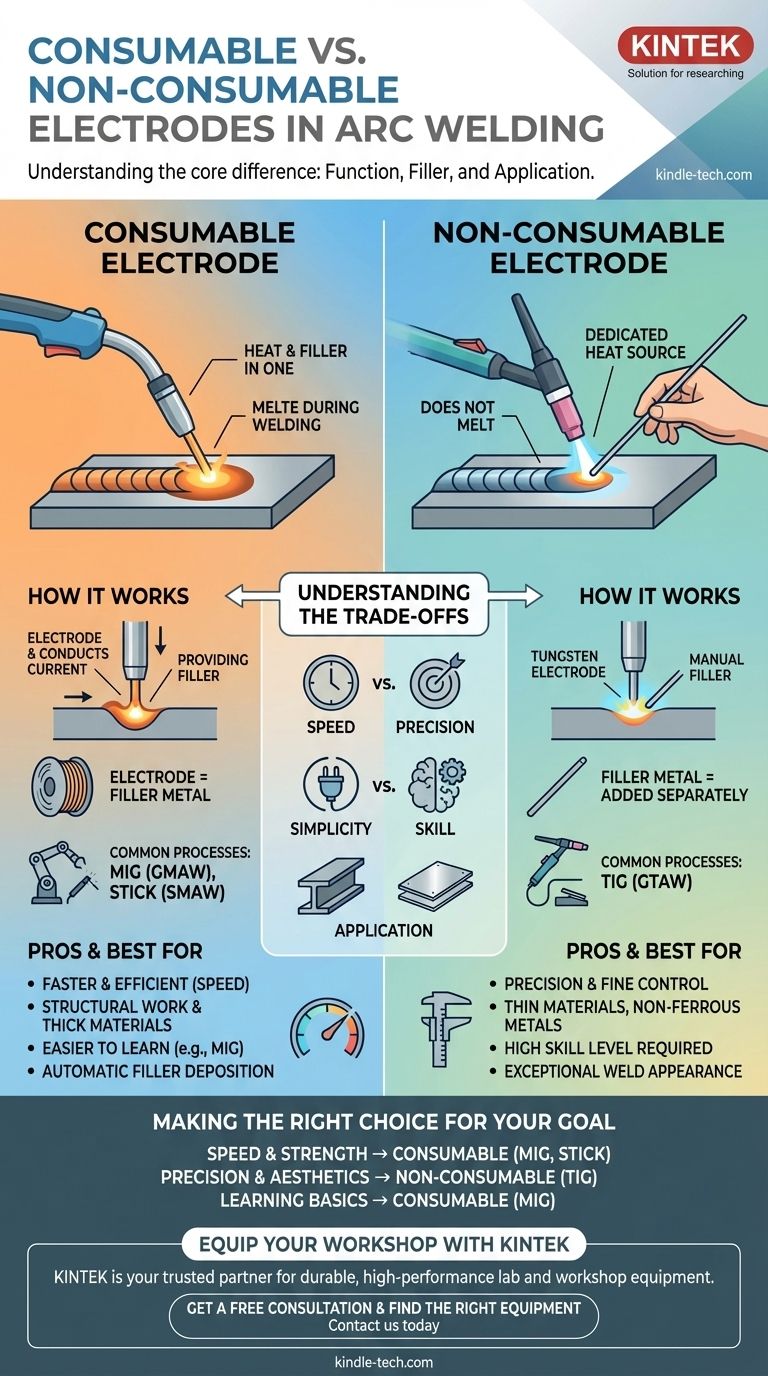

In arc welding, the core difference between a consumable and non-consumable electrode is its function in the process. A consumable electrode melts during welding, becoming the filler metal that joins the workpieces. In contrast, a non-consumable electrode does not melt; its sole purpose is to create and sustain the electrical arc that generates heat, requiring filler metal to be added separately.

The choice between a consumable and non-consumable electrode represents a fundamental trade-off in welding. You are choosing between the combined simplicity and speed of a consumable process and the separate, fine-tuned control offered by a non-consumable one.

The Consumable Electrode: Heat and Filler in One

A consumable electrode is designed to be a multi-purpose tool. It conducts the electric current to create the arc while also melting into the weld pool to provide the filler material.

How It Works

As the electric arc forms between the electrode tip and the workpiece, the intense heat melts both the base metal and the electrode itself. The molten electrode material is then transferred across the arc, becoming an integral part of the final weld bead.

The Role of Filler Metal

In these processes, the electrode is the filler metal. This simplifies the operation, as the welder does not need to manually feed a separate filler rod. The rate of filler deposition is directly linked to the welding parameters, such as wire feed speed and amperage.

Common Consumable Processes

The two most common examples are Shielded Metal Arc Welding (SMAW, or "Stick") and Gas Metal Arc Welding (GMAW, or "MIG"). In Stick welding, the electrode is a flux-coated rod, while in MIG welding, it is a continuous wire fed from a spool.

The Non-Consumable Electrode: A Dedicated Heat Source

A non-consumable electrode is engineered from materials with an extremely high melting point, like tungsten. Its only job is to act as a stable terminal for the electric arc.

How It Works

This type of electrode does not melt or become part of the weld. It simply conducts electricity to generate a concentrated, stable arc, which in turn melts the base metal to create a weld pool.

The Separate Filler Rod

Because the electrode does not provide filler, the welder must add it manually when needed. This is typically done by dabbing a separate filler rod into the molten weld pool with their other hand. This decoupling of heat and filler deposition is the key feature of the process.

The Primary Non-Consumable Process

Gas Tungsten Arc Welding (GTAW, or "TIG") is the definitive non-consumable process. It is renowned for giving the welder exceptional control over the heat input and the amount of filler metal added, resulting in highly precise and clean welds.

Understanding the Trade-offs

Choosing a process means understanding the inherent advantages and disadvantages of its electrode type.

Speed vs. Precision

Consumable electrode processes like MIG are significantly faster because the filler metal is deposited automatically and continuously. Non-consumable TIG welding is a slower, more deliberate process that prioritizes precision and fine control over speed.

Simplicity vs. Skill

For beginners, MIG welding is often considered easier to learn due to its "point-and-shoot" nature. TIG welding, which requires coordinating both hands to manage the torch and the filler rod, demands a much higher level of dexterity and skill to master.

Application and Material

Consumable processes are the workhorses of manufacturing and fabrication, ideal for welding thicker steel quickly and efficiently. Non-consumable TIG welding excels with thin materials, non-ferrous metals (like aluminum and stainless steel), and any application where the final weld appearance is critical.

Making the Right Choice for Your Goal

Your project's goal will dictate which electrode type and corresponding process is the correct tool for the job.

- If your primary focus is fabrication speed and structural strength: Consumable processes like MIG or Stick welding offer the best combination of deposition rate and efficiency.

- If your primary focus is high-precision and aesthetic quality, especially on thin or non-ferrous metals: A non-consumable process like TIG welding is the superior choice for control and finish.

- If your primary focus is learning the basics with a lower initial learning curve: Consumable wire-feed welding (MIG) is often the most accessible starting point for new welders.

Ultimately, understanding this fundamental difference is the first step toward selecting the right tool and mastering the right technique for any welding challenge.

Summary Table:

| Feature | Consumable Electrode | Non-Consumable Electrode |

|---|---|---|

| Function | Provides heat and filler metal | Provides heat only |

| Melts During Welding? | Yes | No (made of high-melting-point materials like tungsten) |

| Filler Metal | Electrode itself is the filler | Added separately by the welder |

| Common Processes | MIG (GMAW), Stick (SMAW) | TIG (GTAW) |

| Best For | Speed, thicker materials, structural work | Precision, thin materials, non-ferrous metals, clean finishes |

| Skill Level | Easier to learn (e.g., MIG) | Requires high skill and dexterity |

Ready to Equip Your Workshop with the Right Welding Tools?

Understanding the electrode is just the first step. Having the right, reliable equipment is what turns knowledge into a perfect weld. Whether you are setting up a new fabrication shop, a research lab, or a educational facility, the quality of your equipment directly impacts your results.

KINTEK is your trusted partner for all lab and workshop equipment needs. We specialize in providing durable, high-performance tools that professionals depend on. Let us help you select the ideal equipment for your specific applications, materials, and skill level.

Contact us today using the form below to discuss your requirements. Our experts are ready to provide personalized recommendations to ensure your projects are a success.

Get a Free Consultation & Find the Right Equipment for Your Needs

Visual Guide

Related Products

- Boron Nitride (BN) Ceramic Rod for High Temperature Applications

- Precision Machined Yttrium Stabilized Zirconia Ceramic Rod for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Alumina Al2O3 Ceramic Rod Insulated for Industrial Applications

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Small Lab Rubber Calendering Machine

People Also Ask

- What are the functions of the Ag/AgCl reference electrode and the platinum wire in (U1−xThx)O2 film oxidation studies?

- How do external pressure-balanced Ag/AgCl electrodes and salt bridges solve HTHP testing challenges?

- What are the examples of electrode materials? From Platinum to Graphite for Your Application

- Why is platinum (Pt) foil utilized as a reference material? Safeguard Purity in Supercritical Water Experiments

- Why is a double-junction pH electrode recommended for monitoring indium electrolytes? Ensure Precision and Longevity

- What is the function of graphite electrodes in EAOPs for PVC microplastics? Enhance Degradation with In Situ Radicals

- What is the thermal stability of graphite? Unlock Its Extreme Heat Potential Safely

- How should a glassy carbon sheet be electrochemically activated before an experiment? A Step-by-Step Guide for Reliable Results