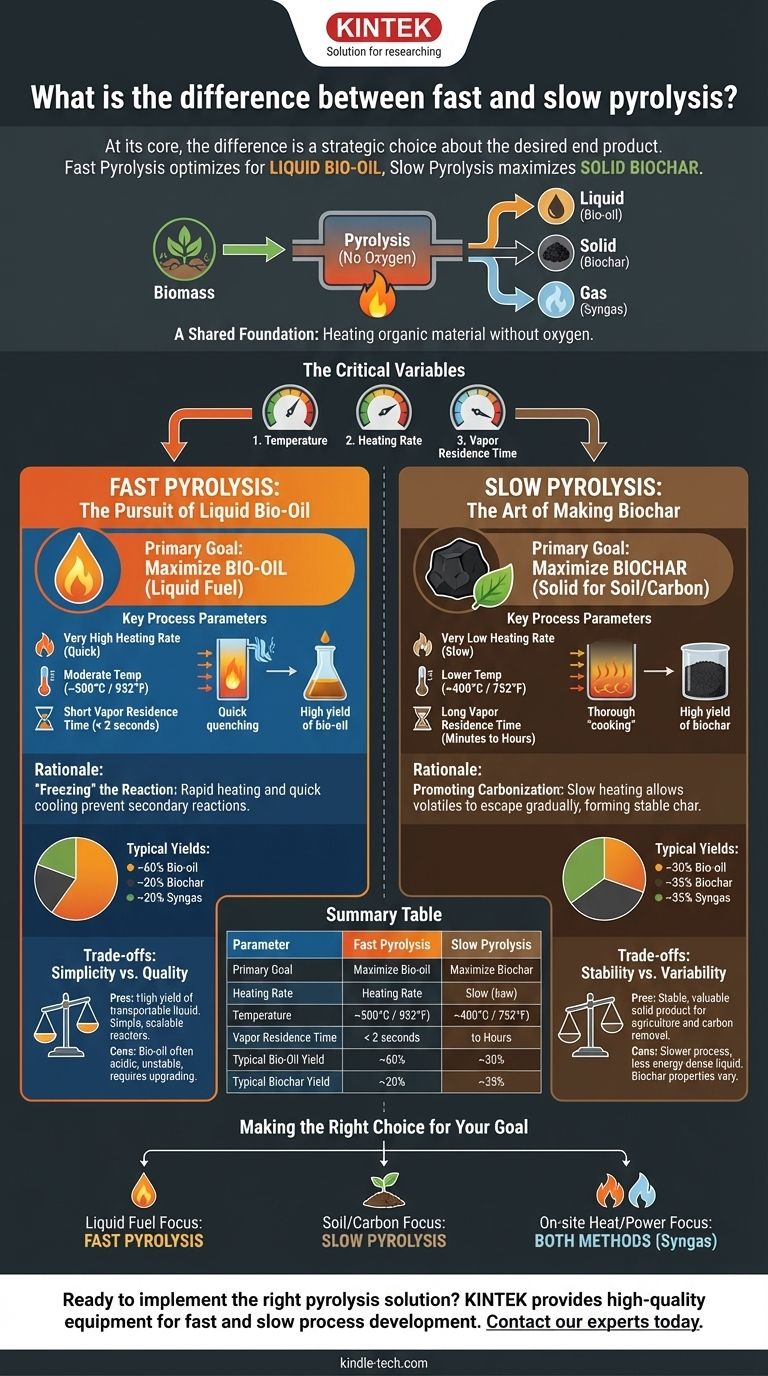

At its core, the difference between fast and slow pyrolysis is a strategic choice about the desired end product. While both processes thermally decompose biomass in the absence of oxygen, fast pyrolysis is optimized to produce a high yield of liquid bio-oil, whereas slow pyrolysis is designed to maximize the output of solid biochar. The speed, temperature, and heating rate are all tools adjusted to achieve one of these two distinct goals.

The fundamental distinction is not the process itself, but its intended outcome. Choose fast pyrolysis if your goal is liquid fuel (bio-oil). Choose slow pyrolysis if your goal is a stable, carbon-rich solid (biochar) for agriculture or carbon sequestration.

A Shared Foundation: The Principle of Pyrolysis

What is Pyrolysis?

Pyrolysis is a process of heating organic material, such as biomass, at high temperatures in an environment without oxygen.

Because there is no oxygen, the material does not combust. Instead, its chemical compounds decompose into a mixture of three products: a liquid (bio-oil), a solid (biochar), and a gas (syngas).

The Critical Variables

The ratio and specific properties of these three products are controlled by three key process parameters:

- Temperature: The heat level inside the reactor.

- Heating Rate: How quickly the biomass reaches the target temperature.

- Vapor Residence Time: How long the gaseous products remain in the hot reaction zone.

It is the manipulation of these variables that defines the difference between fast and slow pyrolysis.

Fast Pyrolysis: The Pursuit of Liquid Bio-Oil

Key Process Parameters

Fast pyrolysis uses a very high heating rate to bring biomass to a moderate temperature of around 500°C (932°F).

Crucially, the resulting vapors are removed and cooled extremely quickly—often in less than two seconds. This short vapor residence time is the defining feature.

The Primary Product: Bio-Oil

This process is optimized to maximize the liquid fraction, yielding up to 75% bio-oil by weight from the initial biomass.

Bio-oil is a dark, dense liquid that can be used as a boiler fuel or upgraded into advanced biofuels and biochemicals. The reference to small, mobile facilities highlights its potential for decentralized production.

The Rationale: "Freezing" the Reaction

The goal of fast pyrolysis is to rapidly break down the biomass and immediately quench the vapors. This quick cooling prevents the vapor-phase molecules from undergoing secondary reactions, which would otherwise form more gas or solid char.

Slow Pyrolysis: The Art of Making Biochar

Key Process Parameters

Slow pyrolysis, true to its name, uses a very low heating rate over a much longer period, often lasting for hours. The temperatures are typically lower, often around 400°C (752°F).

This allows the biomass to slowly and thoroughly "cook" and carbonize, with vapor residence times that can extend for many minutes or even hours.

The Primary Product: Biochar

This process is designed to maximize the solid fraction, yielding roughly 35% biochar.

Biochar is a stable, carbon-rich, charcoal-like material. It is primarily valued not as a fuel, but as a potent soil amendment that improves water retention and nutrient availability, and as a method for long-term carbon sequestration.

The Rationale: Promoting Carbonization

By slowly heating the material, the process allows the volatile components to escape gradually while the carbon structure of the biomass reorganizes and solidifies into a stable char.

Understanding the Trade-offs: A Tale of Three Products

No pyrolysis process is perfect; each involves a compromise between the three possible outputs. Your choice directly dictates the balance of products you will receive.

The Inevitable Product Split

Remember that both processes produce all three products. The difference is the ratio.

- Fast Pyrolysis Yields: ~60% Bio-oil, ~20% Biochar, ~20% Syngas.

- Slow Pyrolysis Yields: ~30% Bio-oil, ~35% Biochar, ~35% Syngas.

(Note: Exact yields vary significantly with feedstock and specific process conditions.)

Fast Pyrolysis: Simplicity vs. Quality

The primary advantage of fast pyrolysis is a high yield of a transportable liquid energy carrier from a wide variety of feedstocks. As the reference material notes, the reactors can be relatively simple and scalable.

The main trade-off is the quality of the bio-oil. It is often acidic, unstable, and contains high levels of water and oxygen, requiring significant and costly upgrading before it can be used as a drop-in transportation fuel.

Slow Pyrolysis: Stability vs. Variability

The key benefit of slow pyrolysis is the production of a stable, valuable solid product. Biochar has immediate applications in agriculture and contributes directly to carbon removal.

The downside is that the process is slower and produces less of the energy-dense liquid fuel. Furthermore, as noted in the references, the properties of the biochar can be highly dependent on the feedstock and conditions, making market consistency a challenge.

Making the Right Choice for Your Goal

Your application dictates which process is the correct one. The decision hinges entirely on the primary product you value most.

- If your primary focus is producing a liquid fuel for energy or upgrading: Fast pyrolysis is the correct and most efficient pathway.

- If your primary focus is soil improvement, waste management, or carbon sequestration: Slow pyrolysis is the superior method for maximizing stable biochar.

- If your primary focus is generating process heat or electricity on-site: Both methods produce syngas, which can be combusted to power the pyrolysis process itself, making either potentially self-sustaining.

Ultimately, understanding the target product is the key to demystifying the world of pyrolysis.

Summary Table:

| Parameter | Fast Pyrolysis | Slow Pyrolysis |

|---|---|---|

| Primary Goal | Maximize bio-oil (liquid fuel) | Maximize biochar (solid for soil/carbon) |

| Heating Rate | Very High | Very Low |

| Temperature | ~500°C (932°F) | ~400°C (752°F) |

| Vapor Residence Time | < 2 seconds | Minutes to hours |

| Typical Bio-Oil Yield | Up to 75% | ~30% |

| Typical Biochar Yield | ~20% | ~35% |

Ready to implement the right pyrolysis solution for your biomass conversion goals?

At KINTEK, we specialize in providing high-quality laboratory equipment and consumables for advanced research and process development. Whether you are optimizing for bio-oil, biochar, or syngas production, our reactors and analytical tools are designed for precision and reliability.

We help our customers in the renewable energy and environmental sectors by:

- Providing robust pyrolysis reactors for both fast and slow process development.

- Supplying essential lab equipment for analyzing bio-oil, biochar, and syngas properties.

- Supporting your R&D with reliable consumables and expert technical support.

Let's build a sustainable future together. Contact our experts today to discuss how KINTEK can support your specific pyrolysis and biomass conversion needs!

Visual Guide

Related Products

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- How are composites processed using sintering? Engineered Material Solutions Through Advanced Thermal Bonding

- What is the function of a high-temperature furnace during burnout? Master Aluminum Foam Production with Precision

- What is a rotary heat type furnace? The Ultimate Guide to Uniform Heating & Mixing

- How do tube furnaces or muffle furnaces ensure stoichiometric accuracy during synthesis? Mastering Li4GeO4 & Li4VO4

- At what temperature does wood pyrolysis begin? Control the Process for Biochar, Bio-Oil, or Syngas