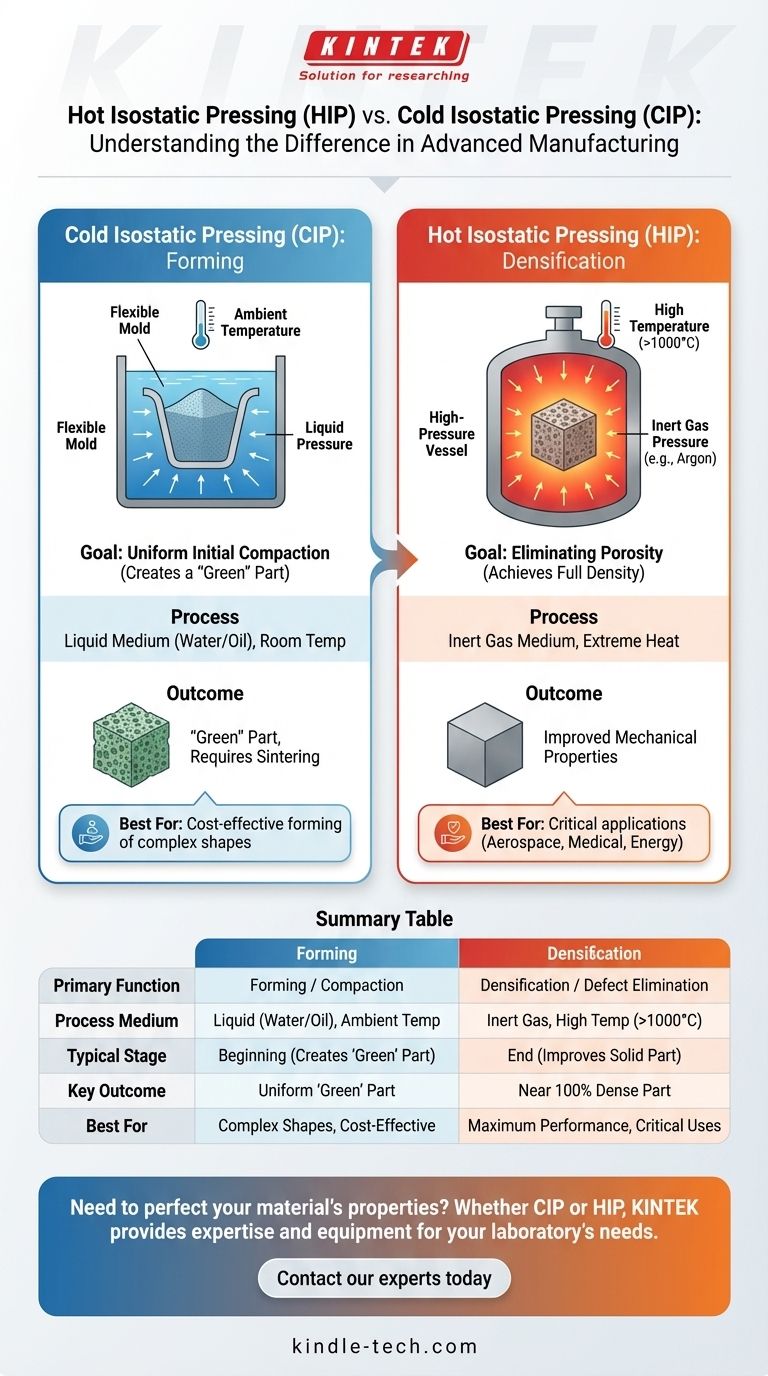

At their core, the fundamental difference between hot and cold isostatic pressing is their purpose within the manufacturing process. Cold Isostatic Pressing (CIP) uses a liquid at ambient temperature to compact powder into a preliminary, handleable shape called a "green" part. Hot Isostatic Pressing (HIP) uses a heated inert gas at high pressure to eliminate internal porosity and achieve full density in a part that is already solid.

The critical distinction is not just temperature, but function. CIP is a forming process used at the beginning of a manufacturing cycle, while HIP is a densification process used at the end to perfect a component's final properties.

What is Cold Isostatic Pressing (CIP)?

Cold Isostatic Pressing is a material processing method that focuses on the initial compaction of powders into a solid mass.

The Goal: Uniform Initial Compaction

The primary objective of CIP is to take a loose powder and press it into a shape with uniform density. This creates a fragile component, known as a "green" part, that has enough structural integrity to be handled and moved to the next manufacturing stage.

The Process: Ambient Temperature, Liquid Pressure

In CIP, the powder is sealed in a flexible, watertight mold. This mold is then submerged in a chamber filled with a liquid, typically water or oil. The chamber is pressurized, applying uniform, isostatic (equal from all directions) pressure to the mold, which compacts the powder inside at room temperature.

The Outcome: A "Green" Part

The resulting part is not at its final strength or density. It must undergo a subsequent high-temperature process called sintering to bond the powder particles together and achieve its final mechanical properties.

What is Hot Isostatic Pressing (HIP)?

Hot Isostatic Pressing is a finishing process designed to perfect the internal structure of an already-formed component.

The Goal: Eliminating Porosity

The main purpose of HIP is to close and eliminate any internal voids, defects, or microscopic pores within a solid part. This is commonly performed on high-performance metal castings or on parts that have already been sintered after a CIP process.

The Process: High Temperature and Gas Pressure

During HIP, a solid component is placed inside a high-pressure containment vessel. The vessel is heated to extremely high temperatures—often over 1,000°C—while also being filled with a high-pressure, inert gas like argon. This combination of heat and pressure causes the material to deform plastically on a microscopic level, forcing internal voids to collapse and fuse together through solid-state diffusion.

The Outcome: A Fully Dense Part

The result is a component with nearly 100% theoretical density. This process dramatically improves mechanical properties such as fatigue life, ductility, and fracture toughness, making it essential for critical applications in aerospace, medical implants, and energy.

Understanding the Trade-offs

Choosing between CIP and HIP is not an "either/or" decision; they serve fundamentally different functions and are often used in sequence.

CIP: Cost-Effective Forming of Complex Shapes

CIP is an excellent method for creating complex initial shapes that would be difficult or impossible to achieve with traditional die pressing. Because the pressure is isostatic, it produces a green part with very uniform density, which reduces warping during the final sintering step. However, it is only a preliminary forming step.

HIP: The Ultimate in Material Performance

HIP provides the highest possible material integrity by removing the internal defects that act as stress concentrators. This performance comes at a cost, as HIP equipment and processing cycles are significantly more complex and expensive than CIP. It is reserved for components where failure is not an option.

Making the Right Choice for Your Goal

The right process depends entirely on what you need to accomplish with your material.

- If your primary focus is to form a complex shape from powder before final sintering: CIP is your method for creating a uniform "green" part that is ready for the furnace.

- If your primary focus is to eliminate internal porosity and achieve maximum density in a cast or sintered part: HIP is the essential final step to enhance mechanical properties and ensure reliability.

Understanding this distinction allows you to select the correct tool to either form or perfect your component in an advanced manufacturing workflow.

Summary Table:

| Feature | Cold Isostatic Pressing (CIP) | Hot Isostatic Pressing (HIP) |

|---|---|---|

| Primary Function | Forming / Compaction | Densification / Defect Elimination |

| Process Medium | Liquid (water/oil) at ambient temperature | Inert gas (e.g., argon) at high temperature (>1000°C) |

| Typical Stage in Manufacturing | Beginning (creates a 'green' part) | End (improves a solid part) |

| Key Outcome | Uniform density 'green' part for sintering | Near 100% dense part with superior mechanical properties |

| Best For | Cost-effective forming of complex shapes | Critical applications requiring maximum performance (aerospace, medical) |

Need to perfect your material's properties? Whether you are forming complex shapes from powder with CIP or aiming for maximum density and performance with HIP, KINTEK has the expertise and equipment to meet your laboratory's advanced manufacturing needs. Our specialized lab equipment and consumables are designed to support critical processes in aerospace, medical, and energy sectors.

Contact our experts today to discuss how our solutions can enhance your workflow and material performance.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Double Plate Heating Press Mold for Lab

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- Is hot isostatic pressing a heat treatment? A Guide to Its Unique Thermomechanical Process

- What is the historical background of the Hot Isostatic Pressing (HIP) process? From Nuclear Roots to Industry Standard

- What is HIP treatment for metal? Eliminate Internal Defects for Superior Part Performance

- What pressure is hot isostatic press? Achieve Full Density & Superior Material Performance

- What are the components of a hot isostatic pressing system? A Guide to Core HIP Equipment