At its core, the difference between hot pressing and Hot Isostatic Pressing (HIP) lies in how pressure is applied. Hot pressing applies force in a single direction (uniaxially), similar to a vise, making it suitable for creating simple shapes. In contrast, HIP applies uniform, gas-based pressure from all directions simultaneously (isostatically), allowing it to consolidate complex shapes to full density.

The choice between these methods depends entirely on your final goal. Hot pressing is a cost-effective tool for producing dense, simple geometries, while HIP is the definitive process for achieving maximum theoretical density and superior material properties, especially in complex components for critical applications.

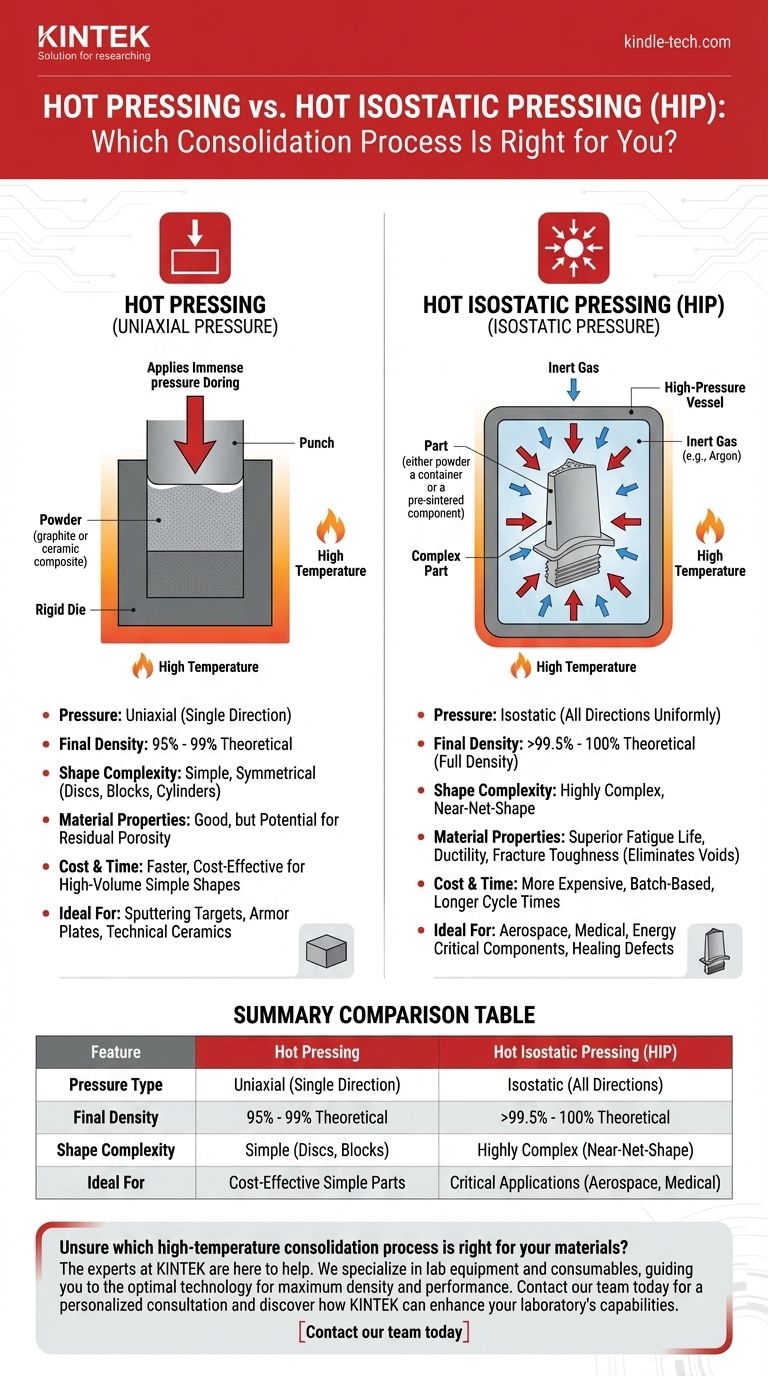

The Fundamental Difference: Uniaxial vs. Isostatic Pressure

To understand when to use each process, you must first grasp the mechanical distinction in how they consolidate materials. This single difference dictates the part geometry, final density, and ultimate performance.

How Hot Pressing Works

Hot pressing involves placing a powder material into a rigid die cavity, typically made of graphite or a ceramic composite.

The assembly is heated to a high temperature, and simultaneously, a punch applies immense pressure along a single vertical axis. This forces the powder particles to deform and bond.

Because the pressure is directional, this method is most effective for producing simple, symmetrical shapes like discs, blocks, and cylinders.

How Hot Isostatic Pressing (HIP) Works

HIP operates on a completely different principle. The part, which is either a powder sealed in a container or a pre-sintered component with closed porosity, is placed inside a high-pressure vessel.

The vessel is heated and then filled with a high-pressure inert gas, such as argon. This gas exerts uniform, isostatic pressure on the part from every direction at once.

This omnidirectional pressure is key. It closes internal voids and porosity without distorting the part's overall geometry, enabling the densification of highly complex shapes.

Comparing the Outcomes: Density, Geometry, and Properties

The differences in pressure application lead to significant variations in the final product. Your material requirements will point clearly toward one process or the other.

Final Density

Hot pressing is very effective at densification, often achieving relative densities between 95% and 99% of the material's theoretical maximum. Some residual porosity may remain, particularly in areas perpendicular to the pressing axis.

HIP is unmatched in its ability to achieve full density. It consistently produces parts with >99.5% to 100% theoretical density, effectively eliminating all internal voids.

Shape Complexity

Hot pressing is limited to simple geometries that can be easily loaded into and ejected from a rigid die. Complex features or undercuts are not possible.

HIP excels with highly complex and near-net-shape parts. Because the gas pressure conforms perfectly to the component's surface, it can densify intricate designs like turbine blades or orthopedic implants.

Material Properties

The superior density from HIP directly translates to superior mechanical properties. By eliminating internal defects, HIP significantly improves a material's fatigue life, ductility, and fracture toughness.

While hot-pressed parts have good properties, the potential for residual porosity makes them less suitable for applications where internal flaws could lead to catastrophic failure.

Understanding the Trade-offs

Choosing a process is not just about performance but also about manufacturing reality. Cost, throughput, and complexity are critical factors.

Cost and Cycle Time

Hot pressing is generally a faster and more cost-effective process for high-volume production of simple shapes. The equipment is less complex, and cycle times are shorter.

HIP is a more expensive, batch-based process with longer cycle times due to the time required to heat, pressurize, and cool the large vessel.

Process Complexity

Hot pressing uses relatively straightforward, reusable die-and-punch tooling. The main challenge is managing die wear and ensuring uniform temperature.

HIP requires more sophisticated infrastructure. If starting from a powder, the material must first be sealed in a metallic or glass "can," which is later removed. This encapsulation adds cost and process steps.

Common Use Cases

Due to its balance of cost and density, hot pressing is often used for producing sputtering targets, armor plates, and simple components from technical ceramics.

HIP is the standard for densifying critical components in aerospace, medical, and energy industries. It is also used as a secondary step to heal internal porosity in castings and additively manufactured parts.

Making the Right Choice for Your Goal

Your decision should be driven by the non-negotiable requirements of your component. Use these guidelines to determine the optimal path.

- If your primary focus is cost-effective production of simple shapes with good density: Hot pressing is the most logical and economical choice.

- If your primary focus is achieving maximum density and superior mechanical properties in complex shapes: Hot Isostatic Pressing is the only process that can meet this need.

- If your primary focus is to heal internal defects in an already-formed part (e.g., a casting or 3D-printed metal): HIP is uniquely suited for this "healing" process to improve part integrity.

Ultimately, understanding the fundamental difference between uniaxial and isostatic pressure empowers you to select the right tool for the job.

Summary Table:

| Feature | Hot Pressing | Hot Isostatic Pressing (HIP) |

|---|---|---|

| Pressure Type | Uniaxial (Single Direction) | Isostatic (All Directions) |

| Final Density | 95% - 99% Theoretical | >99.5% - 100% Theoretical |

| Shape Complexity | Simple (Discs, Blocks) | Highly Complex (Near-Net-Shape) |

| Ideal For | Cost-Effective Simple Parts | Critical Applications (Aerospace, Medical) |

Unsure which high-temperature consolidation process is right for your materials? The experts at KINTEK are here to help. We specialize in lab equipment and consumables, providing solutions for all your material processing needs. Whether you're developing simple ceramic components or complex aerospace parts, we can guide you to the optimal technology for maximum density and performance.

Contact our team today for a personalized consultation and discover how KINTEK can enhance your laboratory's capabilities.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Laboratory High Pressure Vacuum Tube Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the purpose of maintaining a vacuum environment in hot press sintering WCp/Cu? Ensure High Density & Purity

- What are the advantages of using a vacuum hot pressing furnace over HIP? Optimize Fiber-Foil Composite Production

- Why is the vacuum system of a Vacuum Hot Pressing furnace critical for ODS ferritic stainless steel performance?

- What critical processing conditions does a Vacuum Hot-Press Sintering Furnace provide? Achieve High-Performance Composites

- How does vacuum hot-pressing sintering equipment solve W-Si composition segregation? Achieve Material Homogeneity