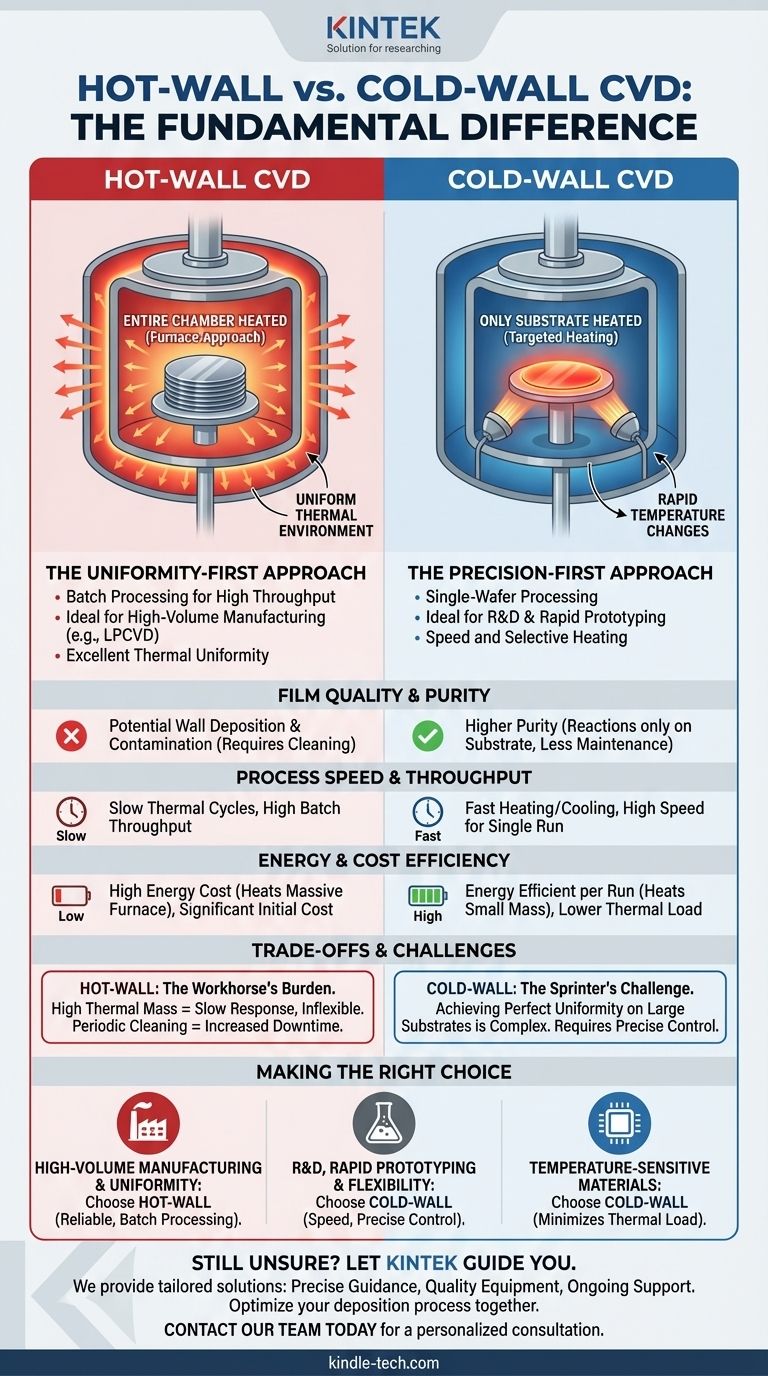

The fundamental difference between hot-wall and cold-wall Chemical Vapor Deposition (CVD) lies in what part of the system is heated. In a hot-wall CVD reactor, the entire process chamber is heated, ensuring a highly uniform temperature environment. In a cold-wall CVD reactor, only the substrate itself is heated, while the chamber walls remain cool.

The choice between a hot-wall or cold-wall system is a strategic trade-off. Hot-wall CVD prioritizes thermal uniformity and batch processing for high-throughput manufacturing, while cold-wall CVD prioritizes speed and selective heating for research, rapid prototyping, and temperature-sensitive applications.

The Core Principle: Where Does the Heat Go?

The method of delivering thermal energy to drive the chemical reaction is the primary distinction between these two architectures. This single design choice has significant consequences for the entire deposition process.

Hot-Wall CVD: The Uniformity-First Approach

In a hot-wall system, the reactor chamber is placed inside a larger furnace. This "oven" approach heats everything—the chamber walls, the gas, and the substrates—to the same target temperature.

This method excels at creating an exceptionally uniform thermal environment. Because the temperature is consistent everywhere, it's ideal for coating many substrates at once in a batch process, which is critical for high-volume manufacturing.

Low-Pressure CVD (LPCVD) is a common technique that often utilizes a hot-wall design to produce highly pure and homogenous films like polysilicon and silicon nitride at high temperatures (typically >600°C).

Cold-Wall CVD: The Precision-First Approach

In a cold-wall system, heating is applied directly and selectively to the substrate holder or the substrate itself, often using methods like resistive heating or lamps. The chamber walls are actively cooled or remain at room temperature.

This targeted heating allows for very rapid temperature changes. The system can heat up and cool down in minutes, drastically shortening process times compared to the hours required for a massive hot-wall furnace.

This makes cold-wall CVD ideal for single-wafer processing, research and development where quick iterations are needed, and for depositing materials where unwanted reactions on the chamber walls could cause contamination.

Why This Difference Matters in Practice

The heating method directly impacts process speed, film quality, and operational costs. Understanding these practical implications is key to selecting the right tool for the job.

Film Quality and Purity

Hot-wall systems can sometimes suffer from unwanted deposition on the chamber walls. Over time, this material can flake off and contaminate the substrates, requiring periodic, time-consuming cleaning cycles.

Cold-wall systems largely avoid this issue. By keeping the chamber walls cool, precursor gases only react on the hot substrate surface, leading to higher film purity and less reactor maintenance.

Process Speed and Throughput

Cold-wall CVD offers superior process speed for a single run due to its rapid heating and cooling capabilities.

However, hot-wall CVD often provides higher overall throughput for established manufacturing. Its ability to process large batches of substrates simultaneously can be more efficient for mass production, despite the long thermal cycles.

Energy and Cost Efficiency

On a per-run basis, cold-wall systems are more energy-efficient. They only expend energy to heat the small mass of the substrate and its holder.

Hot-wall reactors are less efficient, as they must heat the entire, massive furnace chamber. While the operational cost per wafer can be low due to batch processing, the initial capital and energy costs are significant.

Understanding the Trade-offs

Neither method is universally superior; each comes with a distinct set of compromises that makes it suitable for different goals.

Hot-Wall Systems: The Workhorse's Burden

The primary drawback of a hot-wall system is its high thermal mass. It is slow to respond to temperature changes, making it inflexible for processes that require rapid cycling. The need for periodic cleaning due to wall deposition also increases downtime and operational complexity.

Cold-Wall Systems: The Sprinter's Challenge

The main challenge for cold-wall systems is achieving perfect temperature uniformity across a large substrate. Because heat is applied directly, slight variations can create temperature gradients, potentially affecting the consistency and stress of the deposited film. This makes reactor design and process control more complex.

Making the Right Choice for Your Goal

Selecting the correct CVD architecture depends entirely on your primary objective, whether it's production volume, research flexibility, or material constraints.

- If your primary focus is high-volume manufacturing and film uniformity: A hot-wall system, like those used for LPCVD, is the industry standard for its reliability and batch-processing throughput.

- If your primary focus is research, development, or rapid prototyping: A cold-wall system provides the necessary speed, flexibility, and precise control for experimenting with new materials and processes.

- If your primary focus is depositing on temperature-sensitive materials: Cold-wall CVD is the clear choice, as it minimizes the overall thermal load and prevents damage to the underlying substrate or components.

Ultimately, understanding whether to heat the entire process or just the product is the key to mastering your deposition goals.

Summary Table:

| Feature | Hot-Wall CVD | Cold-Wall CVD |

|---|---|---|

| Heating Method | Entire chamber heated in a furnace | Only substrate heated; walls remain cool |

| Primary Advantage | Excellent temperature uniformity | Rapid heating/cooling and process speed |

| Ideal Use Case | High-volume batch manufacturing (e.g., LPCVD) | R&D, rapid prototyping, single-wafer processing |

| Film Purity | Potential for wall deposition and contamination | Higher purity; reactions only on substrate |

| Thermal Mass | High (slow temperature changes) | Low (fast temperature cycles) |

| Energy Efficiency | Lower per run (heats entire chamber) | Higher per run (heats only substrate) |

Still Unsure Which CVD System is Right for Your Lab?

Choosing between hot-wall and cold-wall CVD is a critical decision that impacts your research efficiency, throughput, and film quality. The experts at KINTEK can help you navigate these trade-offs.

We provide tailored solutions for your laboratory needs:

- Precise Guidance: Our technical specialists will analyze your specific application—whether it's high-volume manufacturing requiring hot-wall uniformity or agile R&D needing cold-wall speed—to recommend the optimal system.

- Quality Equipment: KINTEK specializes in reliable lab equipment and consumables, including CVD systems designed for performance and durability.

- Ongoing Support: From installation to maintenance, we ensure your equipment operates at peak performance, minimizing downtime and maximizing your research output.

Let's optimize your deposition process together. Contact our team today for a personalized consultation and discover how KINTEK can enhance your laboratory's capabilities.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

People Also Ask

- What role does Chemical Vapor Deposition (CVD) equipment play in the preparation of C/C composites? Expert Analysis

- What are the methods of producing CNT? Scalable CVD vs. High-Purity Lab Techniques

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision