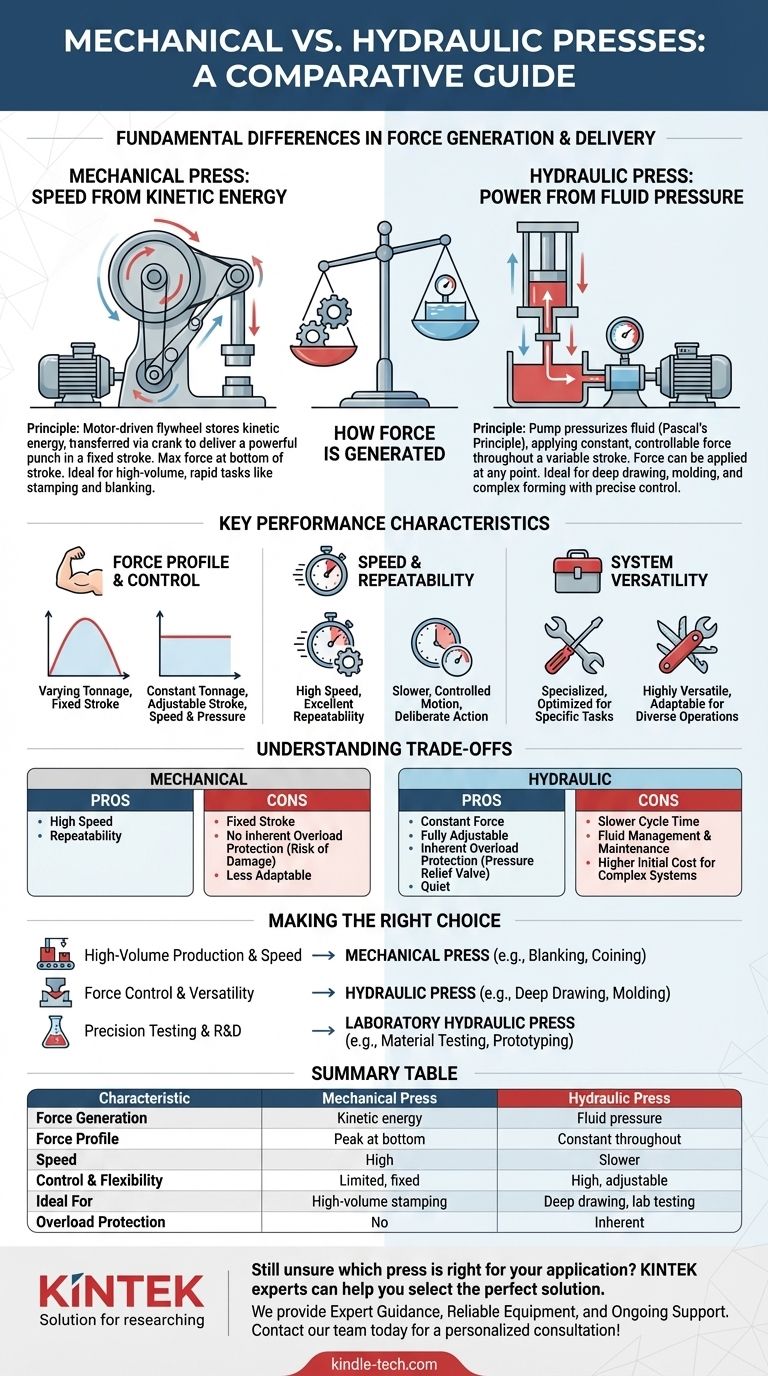

At its core, the fundamental difference between mechanical and hydraulic presses lies in how they generate and deliver force. A mechanical press uses a motor-driven flywheel to store kinetic energy, which is then transferred through a crank mechanism to deliver a powerful punch in a fixed stroke. In contrast, a hydraulic press uses a pump to pressurize fluid, applying a constant, controllable force throughout its variable stroke.

The choice is not about which press is "better," but which force delivery method best suits the task. Mechanical presses offer speed and repeatable precision for high-volume work, while hydraulic presses provide unparalleled force control and flexibility for complex operations.

How Force is Generated: The Core Distinction

Understanding the operational principle of each press is the key to appreciating their distinct advantages and limitations. They are fundamentally different tools designed for different types of work.

The Mechanical Press: Speed from Kinetic Energy

A mechanical press operates on the principle of converting the rotational motion of a flywheel into the linear motion of a ram. A large, heavy flywheel is continuously spun by an electric motor, storing a significant amount of kinetic energy.

When the operator engages the press, a clutch connects the spinning flywheel to a crankshaft, which drives the ram down in a rapid, forceful stroke. The maximum force is only available at the very bottom of the stroke, making it ideal for punching or blanking operations.

The Hydraulic Press: Power from Fluid Pressure

A hydraulic press operates based on Pascal's Principle, which states that pressure applied to a confined fluid is transmitted undiminished throughout the fluid. An electric motor drives a pump, which pushes hydraulic fluid into a cylinder, acting on a piston.

This action generates a controlled, consistent force that can be applied at any point in the ram's travel. The operator has complete control over the force, speed, and duration of the press stroke, offering immense flexibility. Because there are fewer moving parts in the force-generating system, they are also significantly quieter.

Comparing Key Performance Characteristics

The differences in how force is generated lead directly to different performance characteristics. The right choice depends entirely on the specific requirements of your application.

Force Profile and Control

A key differentiator is the force profile. A mechanical press delivers a pre-set, non-adjustable stroke length, with tonnage varying throughout the stroke and peaking at the bottom.

A hydraulic press delivers full, constant tonnage at any point in the stroke. The stroke length, pressure, and ram speed are all fully adjustable, giving the operator precise control over the entire process.

Speed and Repeatability

Mechanical presses are built for speed. Their fast, repeatable stroke cycle makes them the industry standard for high-volume stamping, blanking, and coining where throughput is the primary metric.

Hydraulic presses are generally slower. However, this slower, more deliberate action is an advantage in applications like deep drawing, where controlled material flow is critical to preventing tears and defects.

System Versatility

The design of a hydraulic press is inherently more versatile. Systems can be simple, single-cylinder units or complex multi-cylinder machines for large or intricate forming operations. This makes them suitable for a wide range of tasks, from laboratory testing to heavy industrial molding.

Mechanical presses are more specialized. Their design is optimized for a specific stroke length and tonnage curve, making them less adaptable to jobs outside their intended scope.

Understanding the Trade-offs

Neither press type is without its compromises. Acknowledging these trade-offs is crucial for making a sound investment.

The Cost of Flexibility (Hydraulic)

While offering superior control, hydraulic presses can have a higher initial cost for complex systems. They also introduce the need for hydraulic fluid management and the potential for leaks, which can be a maintenance concern. Their slower cycle time is a direct trade-off for their process control.

The Rigidity of Speed (Mechanical)

The primary strength of a mechanical press—its speed and fixed stroke—is also its main limitation. It is not easily adaptable to different jobs. Furthermore, if the press is overloaded or "jammed" at the bottom of its stroke, it can cause significant damage to the machine, as the flywheel's energy must be dissipated.

Overload Protection

Modern hydraulic presses have inherent overload protection. A pressure relief valve prevents the system from ever exceeding its maximum rated tonnage, protecting both the tooling and the machine.

A mechanical press has no such inherent protection. It will attempt to complete its stroke with all the energy stored in the flywheel, making it critical to set up the tooling and material correctly to avoid catastrophic failure.

Making the Right Choice for Your Application

Selecting the correct press technology requires a clear understanding of your primary operational goal.

- If your primary focus is high-volume production and speed: The rapid cycle times and positional repeatability of a mechanical press are unmatched for applications like blanking and coining.

- If your primary focus is force control and versatility: A hydraulic press offers superior flexibility for deep drawing, molding, or any task requiring adjustable pressure throughout a long stroke.

- If your primary focus is precision testing or R&D: The precise, programmable control of a laboratory hydraulic press is the ideal choice for material testing and prototyping.

By matching the inherent characteristics of the press to the demands of your job, you ensure you are using the most efficient and effective tool for your specific manufacturing goal.

Summary Table:

| Characteristic | Mechanical Press | Hydraulic Press |

|---|---|---|

| Force Generation | Kinetic energy from flywheel & crank | Hydraulic fluid pressure (Pascal's Principle) |

| Force Profile | Peak force at bottom of fixed stroke | Full, constant force throughout variable stroke |

| Speed | High (fast, repeatable strokes) | Slower (deliberate, controlled strokes) |

| Control & Flexibility | Limited; fixed stroke and tonnage curve | High; adjustable pressure, speed, and stroke |

| Ideal For | High-volume stamping, blanking, coining | Deep drawing, molding, complex forming, lab testing |

| Overload Protection | No inherent protection; risk of machine damage | Inherent (pressure relief valve) protects machine/tooling |

Still Unsure Which Press is Right for Your Application?

At KINTEK, we specialize in providing the right lab and industrial equipment for your specific needs. Whether your priority is high-volume speed with a mechanical press or precise force control with a hydraulic press, our experts can help you select the perfect solution.

We provide:

- Expert Guidance: Tailored recommendations based on your materials, processes, and production goals.

- Reliable Equipment: High-quality mechanical and hydraulic presses built for performance and durability.

- Ongoing Support: Comprehensive service to keep your operations running smoothly.

Let's find your ideal press solution. Contact our team today for a personalized consultation!

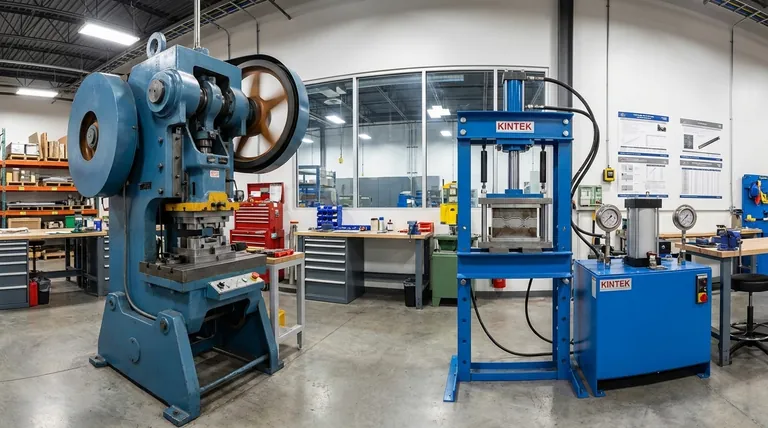

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Manual Lab Heat Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy