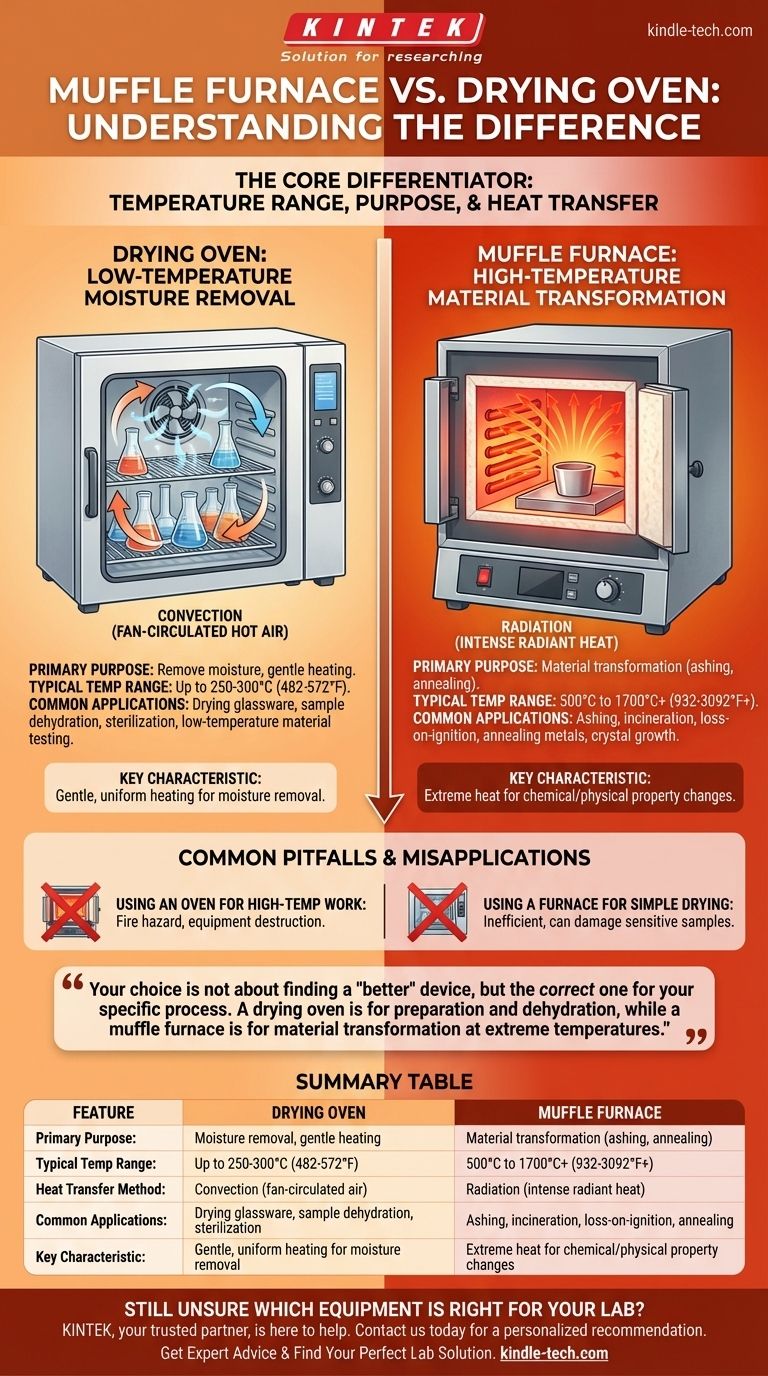

The fundamental difference between a muffle furnace and a drying oven lies in their operating temperature, method of heat transfer, and ultimate purpose. A drying oven uses fan-circulated hot air (convection) at relatively low temperatures to remove moisture and perform gentle heating. In contrast, a muffle furnace uses intense radiant heat at extremely high temperatures to fundamentally alter a material's chemical or physical properties, such as in ashing or annealing.

Your choice is not about finding a "better" device, but the correct one for your specific process. A drying oven is for preparation and dehydration, while a muffle furnace is for material transformation at extreme temperatures.

The Core Differentiator: Temperature Range and Purpose

The most immediate distinction between these two pieces of equipment is the temperature they can achieve, which directly dictates their use cases.

Drying Ovens: Low-Temperature Moisture Removal

A laboratory drying oven typically operates in a range from just above ambient temperature to around 250°C (482°F), with some models reaching 300°C.

Their primary function is to remove moisture from samples or to heat materials gently. Common applications include drying laboratory glassware, sample dehydration, and sterilization.

Muffle Furnaces: High-Temperature Material Transformation

A muffle furnace, also known as a lab furnace, operates at much higher temperatures, typically starting around 500°C and reaching upwards of 1700°C (3092°F).

These are used for processes that require extreme heat to change a material's composition. Key applications include ashing, incineration, loss-on-ignition analysis, annealing metals, and crystal growth.

How They Work: Convection vs. Radiation

The method used to transfer heat is a critical and defining difference between the two.

The Role of Convection in a Drying Oven

Heat transfer in a drying oven primarily occurs through convection. A fan circulates air past a heating element and throughout the chamber.

This moving hot air ensures a uniform and relatively gentle distribution of heat, which is ideal for efficiently removing moisture from a sample's surface.

The Role of Radiation in a Muffle Furnace

A muffle furnace transfers heat primarily through radiation. The heating elements heat the internal chamber, which then radiates intense energy uniformly onto the sample.

The "muffle" itself is a specialized insulating chamber, often made of ceramic fiber, that protects the sample from direct contact with the heating elements. This prevents contamination and ensures even heating at extreme temperatures. This advanced insulation also allows for much faster heating ramp rates.

Common Pitfalls and Misapplications

Using the wrong instrument can lead to damaged equipment, ruined samples, and invalid results. Understanding what not to do is as important as knowing their primary functions.

Using an Oven for High-Temperature Work

This is the most dangerous mistake. A drying oven is not designed for the extreme temperatures of a furnace. Attempting to push it beyond its limit is a fire hazard and will destroy the equipment.

Using a Furnace for Simple Drying

While a furnace can operate at lower temperatures, it is highly inefficient for simple drying tasks. More importantly, the intense radiant heat—even at a lower setting—can damage sensitive samples that would be unharmed by the gentle, circulated air of a drying oven.

Making the Right Choice for Your Process

Your specific goal is the only factor that matters when selecting between these instruments.

- If your primary focus is removing moisture or gentle heating: A drying oven is the correct, efficient, and safe tool for applications like drying glassware, sample dehydration, or low-temperature material testing.

- If your primary focus is altering a material's composition: A muffle furnace is required for high-temperature processes like ashing to determine organic content, performing loss-on-ignition, or annealing metals.

- If your primary focus is cultivating biological samples: Neither is appropriate. You need a laboratory incubator, which provides stable, gentle heat in a much lower temperature range (typically up to 70°C).

Understanding these core differences in mechanism and purpose ensures the integrity of your results and the safety of your lab.

Summary Table:

| Feature | Drying Oven | Muffle Furnace |

|---|---|---|

| Primary Purpose | Moisture removal, gentle heating | Material transformation (ashing, annealing) |

| Typical Temp Range | Up to 250-300°C (482-572°F) | 500°C to 1700°C+ (932-3092°F+) |

| Heat Transfer Method | Convection (fan-circulated air) | Radiation (intense radiant heat) |

| Common Applications | Drying glassware, sample dehydration, sterilization | Ashing, incineration, loss-on-ignition, annealing |

| Key Characteristic | Gentle, uniform heating for moisture removal | Extreme heat for chemical/physical property changes |

Still Unsure Which Equipment is Right for Your Lab?

Choosing the correct tool is critical for your results and safety. KINTEK, your trusted partner in laboratory equipment, is here to help.

We specialize in providing high-quality muffle furnaces for high-temperature applications like ashing and annealing, and reliable drying ovens for precise moisture removal and gentle heating. Our experts can guide you to the perfect solution for your specific process needs.

Contact us today to discuss your application and get a personalized recommendation. Let KINTEK ensure you have the right equipment for accurate and efficient lab work.

Get Expert Advice & Find Your Perfect Lab Solution

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the debinding process? A Guide to Critical Binder Removal for MIM & 3D Printing

- Is muffle furnace a vacuum? Choosing the Right High-Temperature Solution for Your Lab

- How accurate is the muffle furnace? Achieve ±1°C Control and ±2°C Uniformity

- What is the difference between cold type and hot type? Uncover the Printing Revolution

- How is the ash content determined in a muffle furnace? Master the Gravimetric Analysis Method