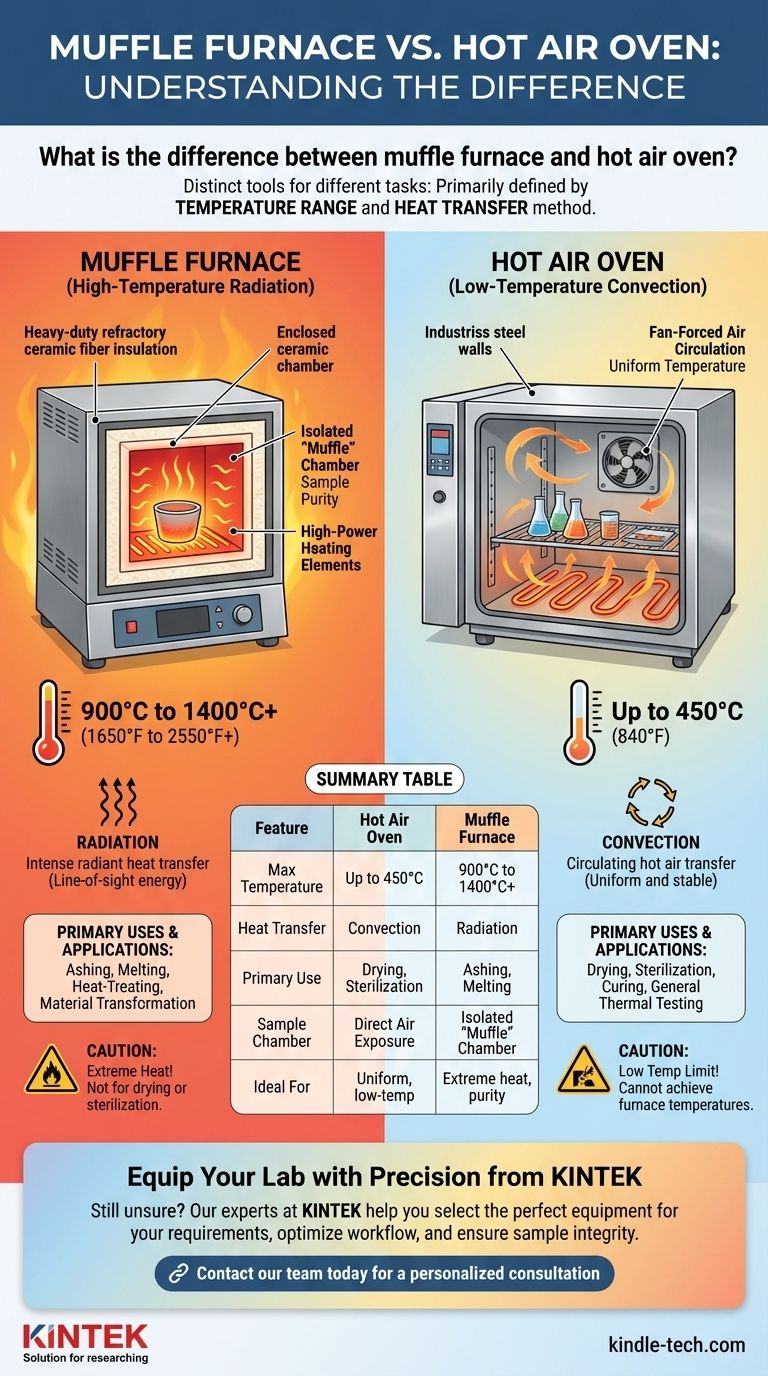

At first glance, a muffle furnace and a hot air oven appear similar, but they are fundamentally different tools designed for vastly different tasks. The primary distinction lies in their operating temperature range and their method of heat transfer. A hot air oven is a low-temperature device (up to 450°C) that uses fan-forced convection, while a muffle furnace is a high-temperature chamber (900°C to 1400°C or higher) that relies on intense radiant heat.

Your choice is not about which device is "better," but which is engineered for your specific process. A hot air oven is for gentle drying and sterilization via circulating hot air. A muffle furnace is for transforming materials through extreme, radiant heat in an isolated chamber.

The Core Differentiator: Temperature and Heat Transfer

The function and design of each device are dictated by the temperatures they must achieve and how they deliver that heat to a sample.

The Hot Air Oven: Low-Temperature Convection

A hot air oven operates in a temperature range typically between ambient +5°C and 450°C (840°F).

Its primary mechanism is convection. Heating elements warm the air inside the chamber, and a fan actively circulates this hot air. This ensures a uniform and stable temperature throughout the chamber.

Think of it as a highly precise, industrial-grade version of a kitchen convection oven. It is ideal for processes like drying glassware, sterilizing equipment, curing polymers, and performing general-purpose thermal testing.

The Muffle Furnace: High-Temperature Radiation

A muffle furnace is built for extreme temperature applications, commonly operating from 900°C to 1400°C (1650°F to 2550°F), with some models exceeding 1700°C.

Its primary mechanism is radiation. High-power heating elements (such as silicon carbide or molybdenum disilicide rods) heat the internal chamber walls until they glow. This incandescent surface radiates intense thermal energy directly to the sample.

Air circulation is not a factor. The sample is heated by the line-of-sight energy transfer from the superheated walls, similar to how the sun heats the Earth. This method is necessary to achieve the temperatures required for melting metals, ashing biological samples, or heat-treating ceramics.

Understanding the Design and Construction

The extreme temperature difference mandates completely different engineering approaches for safety, insulation, and sample integrity.

The "Muffle" and Sample Purity

The name "muffle furnace" comes from its key component: the muffle. This is a separate, sealed inner chamber, typically made of high-temperature ceramic.

This chamber isolates the sample from the heating elements themselves. This is critical for analytical work like ashing, as it prevents any contaminants from the degrading elements from falling into and corrupting the sample's final weight.

Hot air ovens do not have a muffle; the sample is directly exposed to the circulating air and the heating elements.

Insulation and Chamber Materials

A furnace requires thick, multi-layered refractory ceramic fiber insulation to safely contain its immense heat. Its chamber must be made of materials that can withstand thermal shock and extreme temperatures without degrading.

A hot air oven uses less robust insulation, like mineral wool, and stainless steel chambers. These materials are perfectly adequate for lower temperatures but would fail catastrophically at furnace-level heat.

Common Pitfalls and Misapplications

Using the wrong device is not just inefficient; it can be dangerous and will ruin your process.

Why You Can't Use an Oven for Furnace Work

This is a matter of capability and safety. A hot air oven simply cannot reach the high temperatures required for processes like ashing or annealing. Attempting to push it beyond its design limits would destroy the heating elements, seals, and electronics, creating a significant fire hazard.

Why You Can't Use a Furnace for Oven Work

While a furnace can technically be set to a low temperature, it is the wrong tool for several reasons:

- Poor Temperature Control: Furnaces are designed for brute-force heating. They lack the fine control and uniformity needed to hold a precise low temperature, like 150°C.

- Massive Inefficiency: Using a high-power furnace for a low-temperature task is like using a rocket engine to power a bicycle. It wastes an enormous amount of energy.

- Lack of Convection: Processes like drying depend on circulating air to carry away moisture. A furnace, which relies on static radiant heat, is ineffective for this.

Making the Right Choice for Your Application

The correct choice depends entirely on the temperature and process goal. Use this simple guide to select the right equipment.

- If your primary focus is drying, sterilization, or curing below 450°C: A hot air oven provides the necessary convection, temperature stability, and efficiency.

- If your primary focus is ashing, melting, or heat-treating materials above 900°C: A muffle furnace is the only tool that can safely generate the required radiant heat.

- If your primary focus is gentle heating with high precision: The fan-driven uniformity of a hot air oven is critical.

- If your primary focus is material transformation and analytical purity: The muffle furnace's isolated chamber protects your sample from contamination at extreme temperatures.

Choosing the correct heating device ensures the safety of your lab, the efficiency of your workflow, and the integrity of your results.

Summary Table:

| Feature | Hot Air Oven | Muffle Furnace |

|---|---|---|

| Max Temperature | Up to 450°C (840°F) | 900°C to 1400°C+ (1650°F to 2550°F+) |

| Heat Transfer | Convection (Fan-Forced Air) | Radiation (Radiant Heat) |

| Primary Use | Drying, Sterilization, Curing | Ashing, Melting, Heat-Treating |

| Sample Chamber | Direct Air Exposure | Isolated "Muffle" Chamber |

| Ideal For | Uniform, low-temperature processes | Extreme heat, sample purity |

Equip Your Lab with Precision from KINTEK

Still unsure whether a muffle furnace or hot air oven is the right solution for your specific application? Our experts at KINTEK are here to help. We specialize in providing the precise lab equipment and consumables your laboratory needs to operate safely and efficiently.

We can help you:

- Select the perfect equipment based on your temperature requirements and process goals.

- Optimize your workflow with reliable, high-performance tools.

- Ensure sample integrity and safety with the right technology for the job.

Don't risk your process with the wrong tool. Contact our team today for a personalized consultation and discover the KINTEK difference in laboratory excellence.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the muffle furnace analysis? Achieve Pure, High-Temperature Processing for Your Materials

- What is the use of muffle furnace in pharmaceutical industry? Ensure Drug Purity with Precise High-Temp Analysis

- Why must a constant temperature drying oven be used for graphite samples? Ensure High-Precision Material Integrity

- What are the primary functions of a high-temperature box furnace? Master the Sintering of Glass-Ceramic Coatings

- What critical function does a laboratory box-type high-temperature muffle furnace perform in alumina calcination?

- How many types of quenching are there? Master the Techniques for Optimal Steel Hardening

- What is muffle in muffle furnace? The Key to Contamination-Free High-Temperature Processing

- What is the dry ashing method? A Simple and Cost-Effective Analytical Technique