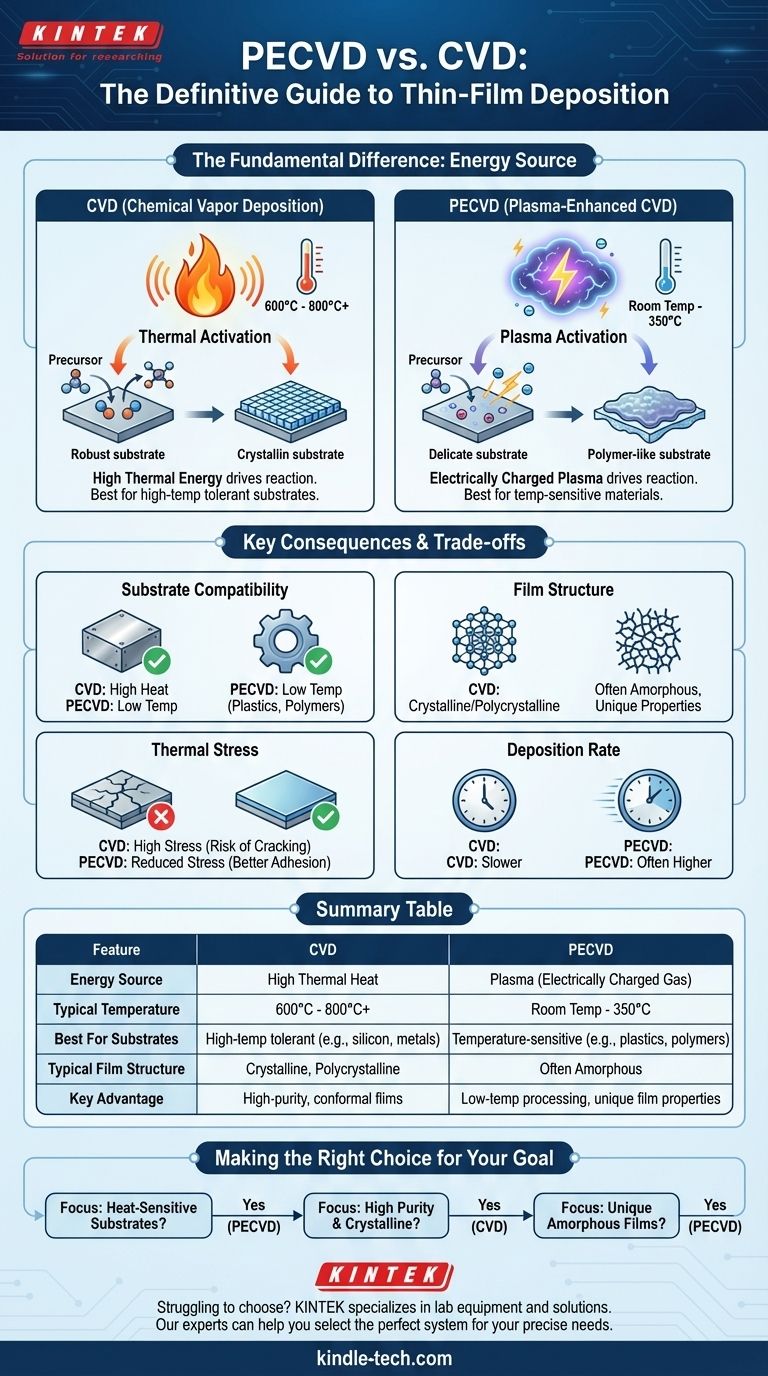

The fundamental difference between PECVD and CVD is the energy source used to drive the chemical reaction. Traditional Chemical Vapor Deposition (CVD) relies on high heat, often 600°C or higher, to provide the thermal energy needed to break down precursor gases and deposit a thin film. In contrast, Plasma-Enhanced Chemical Vapor Deposition (PECVD) uses an electrically charged gas (a plasma) to supply this energy, allowing the process to occur at much lower temperatures, typically below 350°C.

While both methods deposit thin films from a gas phase, PECVD's use of plasma instead of high heat is the critical distinction. This substitution enables deposition on temperature-sensitive materials and allows for the creation of unique film structures not achievable with conventional thermal processes.

How the Energy Source Defines the Process

The choice between thermal energy and plasma energy has profound implications for the entire deposition process, from operating conditions to the final material properties.

Thermal Activation in Conventional CVD

Conventional CVD is a thermally-driven process. The substrate is heated to very high temperatures (typically 600°C to 800°C), providing the activation energy required for the precursor gas molecules to react and form a solid film on the substrate surface.

The process is governed by thermal kinetics, meaning the reactions are predictable based on temperature and pressure.

Plasma Activation in PECVD

PECVD operates on a different principle. Instead of heat, it uses an electric field to ionize a gas, creating a plasma. This plasma is a highly energetic environment filled with ions and free electrons.

These high-energy electrons collide with the precursor gas molecules, breaking chemical bonds and creating reactive radicals. This "activates" the chemical reaction without requiring high temperatures, which is why the process can run at much cooler temperatures (room temperature to 350°C).

Key Consequences of Using Plasma vs. Heat

This fundamental difference in energy source leads to several critical distinctions that determine which method is suitable for a given application.

Substrate Compatibility

The most significant advantage of PECVD is its low operating temperature. This makes it ideal for depositing films on substrates that cannot withstand the intense heat of conventional CVD, such as plastics, polymers, and complex semiconductor devices with pre-existing layers.

Film Structure and Properties

The energy source directly influences the type of film produced. Thermal CVD processes are often limited by equilibrium kinetics, typically producing crystalline or polycrystalline films.

PECVD's plasma environment creates non-equilibrium conditions. The high-energy, non-selective electron bombardment can result in completely different film structures, often forming unique amorphous films that have distinct optical and mechanical properties.

Reduced Thermal Stress

The high temperatures in conventional CVD can induce significant thermal stress in both the substrate and the newly deposited film, potentially leading to cracking or delamination.

PECVD's low-temperature nature drastically reduces this thermal stress, improving film adhesion and the overall integrity of the coated component.

Deposition Rate

By using plasma to activate the precursors, PECVD can often achieve higher deposition rates at lower temperatures compared to thermal CVD. This can improve throughput and overall process efficiency in a manufacturing environment.

Understanding the Trade-offs

While PECVD offers significant advantages, it is not a universal replacement for thermal CVD. Each process has its place.

The Simplicity of Thermal CVD

For applications where the substrate can tolerate high heat, thermal CVD can be a simpler, more robust process. It doesn't require complex RF power supplies and plasma containment systems, and it is often the preferred method for depositing very high-purity, highly conformal, crystalline films.

The Complexity of PECVD

Introducing plasma adds several variables to the process, including RF power, frequency, and gas pressure, all of which must be precisely controlled. The plasma itself can also cause ion bombardment damage to the substrate surface if not carefully managed.

Film Purity and Contamination

The plasma in a PECVD system can sometimes sputter material from the chamber walls, which can then be incorporated into the growing film as an impurity. Additionally, because the reactions are less selective, hydrogen is often incorporated into PECVD films, which can be undesirable for certain electronic applications.

Making the Right Choice for Your Goal

Selecting the correct deposition method requires a clear understanding of your material, substrate, and desired outcome.

- If your primary focus is depositing on heat-sensitive substrates: PECVD is the definitive choice due to its low-temperature operation.

- If your primary focus is achieving high-purity, crystalline films and the substrate can tolerate heat: Traditional thermal CVD is often the more straightforward and effective method.

- If your primary focus is creating unique, amorphous film structures: PECVD provides the non-equilibrium reaction environment necessary for these materials.

Ultimately, understanding that CVD is a heat-driven process while PECVD is a plasma-driven process is the key to selecting the right tool for your specific application.

Summary Table:

| Feature | CVD (Chemical Vapor Deposition) | PECVD (Plasma-Enhanced CVD) |

|---|---|---|

| Energy Source | High Thermal Energy (Heat) | Plasma (Electrically Charged Gas) |

| Typical Temperature | 600°C - 800°C+ | Room Temp - 350°C |

| Best For Substrates | High-temperature tolerant (e.g., silicon, metals) | Temperature-sensitive (e.g., plastics, polymers) |

| Typical Film Structure | Crystalline, Polycrystalline | Often Amorphous |

| Key Advantage | High-purity, conformal films | Low-temperature processing, unique film properties |

Struggling to choose the right deposition process for your materials? The choice between PECVD and CVD is critical for your project's success. KINTEK specializes in lab equipment and consumables, providing expert solutions for all your laboratory needs. Our team can help you select the perfect system to achieve the precise film properties and substrate compatibility you require.

Let's optimize your thin-film deposition process together. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- How plasma is generated in PECVD? A Step-by-Step Breakdown of the Process

- What are the advantages of using PECVD for CNT synthesis? Unlock High-Performance Photoelectrode Preparation

- What are the advantages of using a PECVD system for DLC films? Achieve Low-Temp Precision for Sensitive Substrates

- What are the improvements and applications of HDPCVD? Solve High-Aspect-Ratio Gap Filling in Semiconductors

- What is the plasma source? A Guide to Generating and Controlling Ionized Gas for Industrial Applications

- What are the properties of silicon dioxide film deposited by PECVD at low temperature pressure? Achieve Superior Insulation on Sensitive Substrates

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is the process of PACVD? Achieve High-Quality Coatings at Lower Temperatures