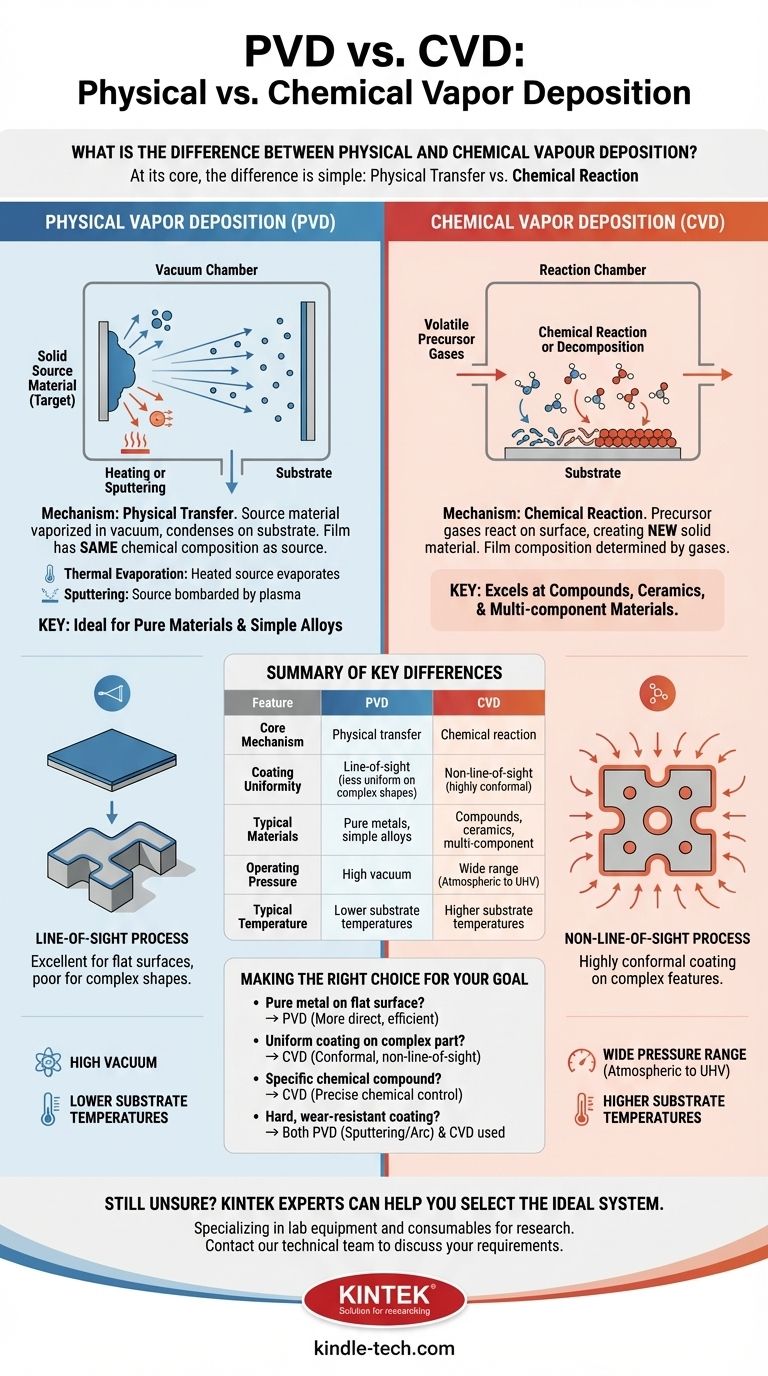

At its core, the difference is simple. Physical Vapor Deposition (PVD) uses a physical process—like heating or sputtering—to turn a solid source material into a vapor that coats a substrate. Chemical Vapor Deposition (CVD) uses a chemical reaction between precursor gases to create an entirely new solid material that then forms a film on the substrate.

The fundamental distinction is how the coating material is generated. PVD physically transfers an existing material from a source to a substrate, while CVD synthesizes a new material directly on the substrate through a chemical reaction.

The Core Mechanism: Physical Transfer vs. Chemical Reaction

To select the right process, you must first understand how each one fundamentally operates. The name of each technique accurately describes its mechanism.

How PVD Works: A Physical Process

PVD is a line-of-sight process where a solid source material, or "target," is vaporized inside a vacuum chamber.

The atoms or molecules of this vapor then travel in a straight line and condense on the substrate, forming the thin film. The deposited film has the same basic chemical composition as the source material.

There are two primary methods for this:

- Thermal Evaporation: The source material is heated until it evaporates into a gas.

- Sputtering: The source material is bombarded with high-energy ions (a plasma), which physically knock atoms off its surface.

How CVD Works: A Chemical Process

CVD is a chemical process where the substrate is exposed to one or more volatile precursor gases inside a reaction chamber.

These gases react or decompose on the substrate's surface, creating a new, solid material that deposits as the film. The film's composition is determined by the precursor gases and the reaction conditions.

This chemical reaction is typically induced by high temperatures, but can also be enhanced by plasma (PECVD) or light (LICVD).

Key Differences in Application and Results

The difference in mechanism leads to significant differences in the types of films produced and the surfaces they can coat.

Conformal Coating and Complex Shapes

Because PVD is a line-of-sight process, it is excellent for coating flat surfaces but struggles to uniformly coat complex, three-dimensional shapes. The "shadows" cast by the part's geometry can lead to uneven film thickness.

CVD, however, is not limited by line-of-sight. The precursor gases can flow around and into complex features, holes, and recesses, resulting in a highly uniform or "conformal" coating. This is often referred to as CVD's superior "throwing power."

Film Properties and Composition

PVD is ideal for depositing pure materials, such as elemental metals (titanium, aluminum) or simple alloys, directly from a solid target. The process offers a straightforward way to transfer that material onto a surface.

CVD excels at creating films of compounds, including ceramics, alloys, and multi-component materials. By carefully controlling the precursor gases and reaction conditions, you can precisely engineer the film's chemical composition, crystal structure, and grain size.

Operating Conditions

PVD processes almost always require a high vacuum. This is necessary to ensure the vaporized atoms can travel from the target to the substrate without colliding with other gas molecules.

CVD processes can operate over a wide range of pressures, from atmospheric pressure (APCVD) down to an ultrahigh vacuum (UHVCVD). CVD often requires higher substrate temperatures to provide the thermal energy needed to drive the chemical reactions.

Understanding the Trade-offs

Neither method is universally superior; they are tools designed for different tasks, each with distinct advantages and limitations.

The PVD Advantage: Material Purity and Simplicity

PVD's primary strength is its ability to deposit high-purity films of materials that may not have suitable gaseous precursors for CVD. The process is conceptually simpler and is the industry standard for many metallic and hard decorative coatings.

The CVD Advantage: Versatility and Coverage

CVD's strength lies in its unmatched ability to create highly conformal coatings on complex shapes and to synthesize a vast range of compound materials that would be impossible to deposit directly. It can also achieve very high deposition rates, making it economical for thicker coatings.

Common Pitfalls to Avoid

A common mistake with PVD is expecting uniform coverage on intricate parts, leading to poor performance in shadowed areas.

With CVD, challenges can include managing the complex chemistry, handling potentially hazardous precursor gases, and ensuring the high process temperatures do not damage the underlying substrate.

Making the Right Choice for Your Goal

Your application's specific requirements for material, geometry, and film properties will dictate the best choice.

- If your primary focus is applying a pure metal or a simple alloy onto a flat surface: PVD is almost always the more direct and efficient choice.

- If your primary focus is coating the inside of a complex part with a uniform, protective layer: CVD's non-line-of-sight nature is essential for success.

- If your primary focus is creating a film with a very specific chemical compound (e.g., silicon nitride): CVD provides the chemical control needed to synthesize the material in-situ.

- If your primary focus is applying a hard, wear-resistant coating onto cutting tools: Both techniques are used, but PVD methods like sputtering and arc deposition are extremely common and effective.

Ultimately, understanding the core distinction between physical transfer and chemical creation is the key to selecting the right tool for your engineering challenge.

Summary Table:

| Feature | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Core Mechanism | Physical transfer of material | Chemical reaction to create material |

| Coating Uniformity | Line-of-sight; less uniform on complex shapes | Non-line-of-sight; highly conformal |

| Typical Materials | Pure metals, simple alloys | Compounds, ceramics, multi-component materials |

| Operating Pressure | High vacuum | Wide range (atmospheric to UHV) |

| Typical Temperature | Lower substrate temperatures | Higher substrate temperatures |

Still unsure which deposition process is right for your application?

KINTEK specializes in lab equipment and consumables, serving the precise needs of laboratories and R&D facilities. Our experts can help you select the ideal PVD or CVD system to achieve the specific film properties, material composition, and coating uniformity your project demands.

Contact our technical team today to discuss your requirements and discover how our solutions can enhance your research and development outcomes.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings