At their core, sputtering and evaporation are fundamentally different processes for creating thin films. Sputtering is a physical, high-energy process that uses ion bombardment to knock atoms off a source material, while evaporation is a thermal, low-energy process that involves heating a material in a vacuum until it vaporizes and condenses onto a surface. This core mechanical difference dictates every major outcome, from film quality to deposition speed.

The decision between sputtering and evaporation is a classic engineering trade-off. Sputtering delivers superior film adhesion and density at the cost of speed, while evaporation offers significantly higher deposition rates but produces films with weaker adhesion.

The Core Mechanism: Physical vs. Thermal

To understand the practical differences, you must first grasp how each method generates the coating material. These two approaches, both forms of Physical Vapor Deposition (PVD), could not be more distinct.

Sputtering: A Collision-Based Process

Sputtering operates on the principle of momentum transfer. In a vacuum chamber, high-energy ions (typically from an inert gas like argon) are accelerated and collided with a source material, known as the "target."

This energetic impact physically ejects, or "sputters," individual atoms from the target. These atoms travel through the chamber and deposit onto the substrate, forming a thin, dense film.

Evaporation: A Thermal Vaporization Process

Evaporation is a much simpler concept based on changing the state of matter. The source material is placed in a vacuum chamber and heated until it reaches its vaporization temperature.

This creates a robust vapor stream that rises through the chamber and condenses on the cooler substrate. This process is analogous to water boiling in a pot and condensing on a cold lid held above it.

Key Differences in Film Properties

The mechanism directly impacts the final characteristics of the deposited film. The energy of the atoms as they arrive at the substrate is the most critical factor.

Film Adhesion and Density

Sputtered atoms arrive at the substrate with significant kinetic energy. This high energy allows them to embed slightly into the substrate surface, creating a much stronger bond and a denser film structure.

Evaporated atoms, having only thermal energy, land more gently. This results in a less dense film with comparatively weaker adhesion to the substrate.

Deposition Rate and Speed

Evaporation is generally a much faster process. By producing a continuous and robust vapor stream, it can deposit material at a significantly higher rate than sputtering.

Sputtering ejects atoms or small clusters one at a time. This makes it a more controlled but inherently slower deposition method.

Film Uniformity and Quality

Evaporation can produce films with superior large-area thickness uniformity due to the nature of the vapor cloud it creates.

Sputtering, while potentially having minor particle inclusions, produces a more uniform and realistic metal effect with a denser microstructure. This makes it ideal for applications where the film's intrinsic quality is paramount.

Understanding the Trade-offs

Neither method is universally better; the optimal choice depends entirely on the application's specific requirements.

Process Energy and Its Consequences

The high energy of sputtering is its greatest strength (adhesion, density) and a potential weakness. This energy can damage sensitive substrates, such as certain plastics or organic materials.

Evaporation's low-energy nature makes it a gentler process, suitable for delicate substrates that cannot withstand the ion bombardment inherent in sputtering.

Color and Material Versatility

Sputtering offers greater versatility. It allows for the deposition of complex alloys and compounds, and enables color modulation through process control without post-processing.

Evaporation is typically limited to the true color of the source material. Achieving different colors often requires additional steps like spray painting after the deposition is complete.

Scalability and Automation

While evaporation is fast for single runs, sputtering is often considered more scalable and suitable for automated, high-volume manufacturing environments due to its process stability and control.

Making the Right Choice for Your Application

Selecting the correct method requires aligning your primary goal with the inherent strengths of each process.

- If your primary focus is film durability and adhesion: Sputtering is the superior choice due to the high-energy deposition creating a denser, better-bonded film.

- If your primary focus is high-speed deposition for simpler materials: Thermal evaporation provides a much faster and often more cost-effective solution, especially for single-material coatings.

- If your primary focus is coating delicate substrates or achieving excellent thickness uniformity: Evaporation's gentle, low-energy process is often the safer and more effective option.

- If your primary focus is coating complex alloys or achieving specific optical effects: Sputtering offers far greater control and versatility over the final film's composition and properties.

By understanding these core principles, you can confidently select the deposition method that aligns precisely with your material, performance, and production requirements.

Summary Table:

| Feature | Sputtering Deposition | Evaporation Deposition |

|---|---|---|

| Core Mechanism | Momentum transfer via ion bombardment | Thermal vaporization via heating |

| Film Adhesion | Superior (high kinetic energy) | Weaker (low thermal energy) |

| Film Density | High | Lower |

| Deposition Speed | Slower, more controlled | Faster |

| Substrate Compatibility | Can damage delicate materials | Gentle, suitable for delicate substrates |

| Material Versatility | High (alloys, compounds, color control) | Limited (true material color) |

| Best For | Durable coatings, complex alloys, optical effects | High-speed deposition, uniform thickness, delicate materials |

Still unsure which deposition method is right for your project? The experts at KINTEK are here to help. We specialize in providing the ideal lab equipment and consumables for all your thin film deposition needs. Whether you require the superior adhesion of sputtering or the high-speed uniformity of evaporation, we can guide you to the perfect solution for your laboratory. Contact our team today to discuss your specific application and optimize your process!

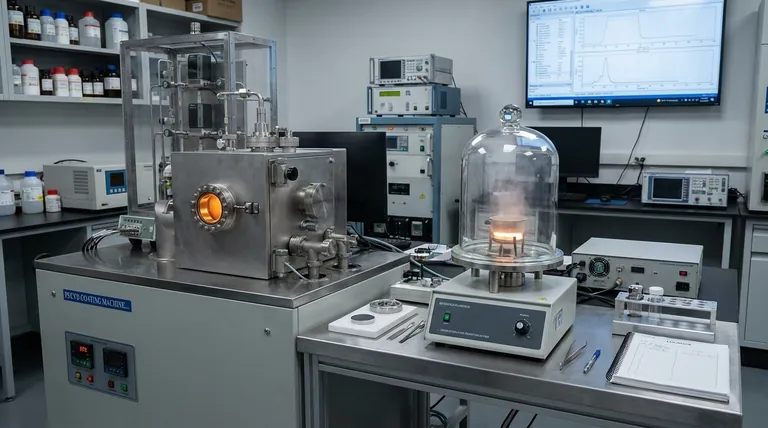

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Custom CVD Diamond Coating for Lab Applications

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What materials can evaporate? Master Thin-Film Deposition with the Right Materials

- What materials are used in e-beam evaporation? From Pure Metals to High-Temp Ceramics

- What is thermal evaporation of organic materials? The Gentle Method for OLED & Electronics

- What is the principle of electron beam deposition? A Guide to High-Speed, Versatile Thin Films

- What is the difference between thermal evaporation and magnetron sputtering? Choose the Right PVD Coating Method

- What is the difference between e-beam and thermal evaporation? Choose the Right PVD Method for Your Materials

- What is the voltage of e-beam evaporation? Achieve Precise Thin-Film Deposition

- What is the evaporation method? A Guide to High-Purity Thin Film Deposition