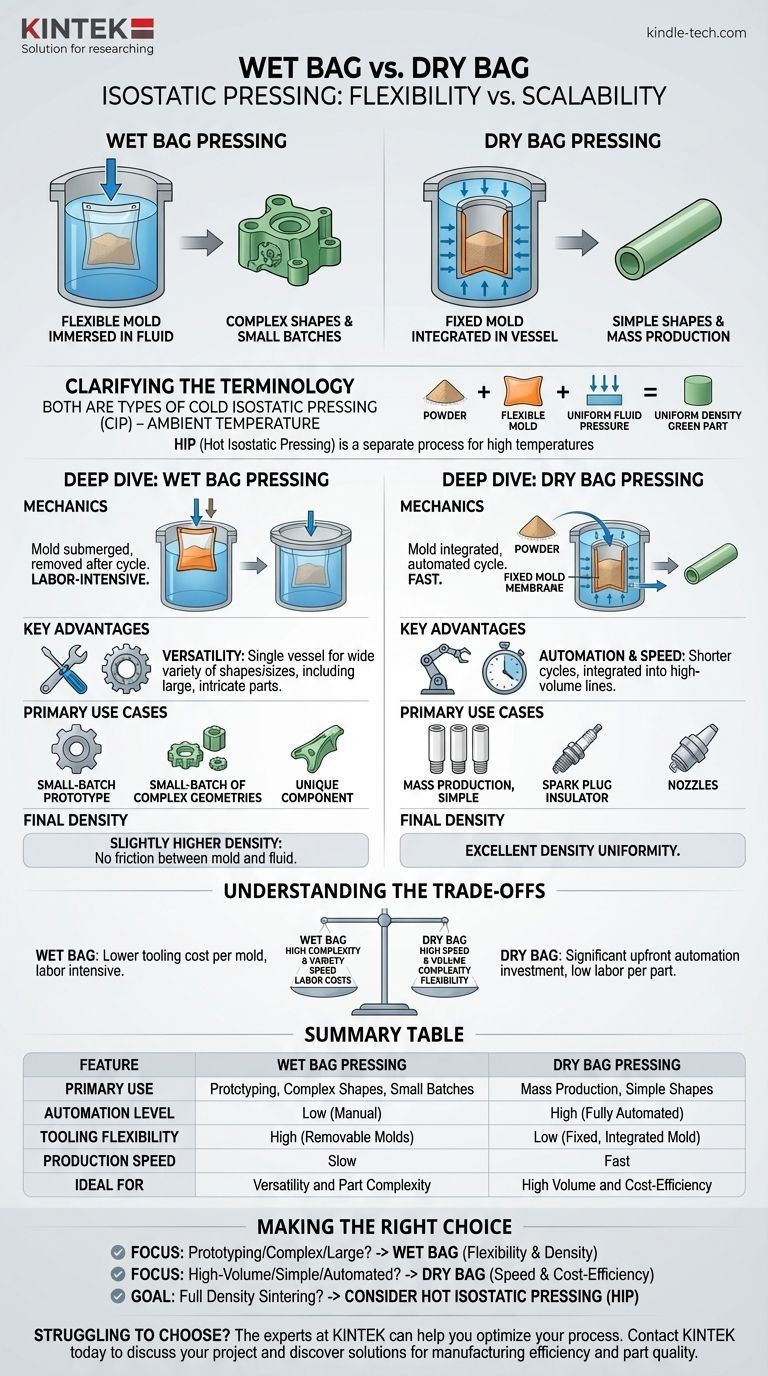

The fundamental difference between wet bag and dry bag isostatic pressing lies in the tooling setup and its resulting production scalability. Wet bag pressing uses a flexible, removable mold immersed in a pressure fluid, making it ideal for complex shapes and small batches. In contrast, dry bag pressing integrates the mold directly into the pressure vessel, a design that enables high-speed, automated production of simpler parts.

The choice between wet and dry bag methods is a strategic decision between manufacturing flexibility and production volume. While both are types of Cold Isostatic Pressing (CIP), wet bag offers versatility for prototypes and complex components, whereas dry bag provides the efficiency required for mass production.

Clarifying the Terminology: A Critical Distinction

A Common Point of Confusion

Before comparing methods, it's crucial to understand their place in the broader context. The terms "wet bag" and "dry bag" refer to two distinct tooling methodologies used within Cold Isostatic Pressing (CIP), which occurs at ambient temperatures.

This is often confused with the primary categories of isostatic pressing: Cold Isostatic Pressing (CIP) and Hot Isostatic Pressing (HIP). HIP is a separate process used to fully consolidate parts at high temperatures and pressures, often to eliminate final porosity after sintering.

The Core Principle of Isostatic Pressing

Both wet and dry bag CIP operate on the same principle: a powdered material is placed in a flexible mold, and uniform ("isostatic") pressure is applied through a fluid. This omnidirectional pressure compacts the powder into a solid "green" part with highly consistent density.

Deep Dive: Wet Bag Isostatic Pressing

The Mechanics

In wet bag pressing, the powder is filled into a flexible, sealed mold. This entire mold is then submerged in a high-pressure vessel filled with a fluid, typically water or oil. Once the pressure cycle is complete, the mold is manually removed from the vessel.

Key Advantages

The primary advantage of the wet bag method is its versatility. Because the mold is not a permanent part of the machinery, a single pressure vessel can be used to produce a wide variety of shapes and sizes, including large and intricate components.

Primary Use Cases

This method is best suited for small-batch production, prototyping, and manufacturing parts with complex geometries that would be difficult or impossible to create with other methods.

Deep Dive: Dry Bag Isostatic Pressing

The Mechanics

In dry bag pressing, the flexible mold is permanently integrated into the pressure vessel itself. The "bag" is a fixed membrane that separates the powder from the pressurizing fluid. Powder is loaded into the cavity, pressure is applied, and the compacted part is ejected, often automatically.

Key Advantages

The defining advantage of dry bag pressing is its suitability for automation and speed. The fixed tooling and streamlined process allow for much shorter cycle times and integration into high-volume production lines.

Primary Use Cases

This method excels at the mass production of parts with relatively simple, consistent shapes, such as ceramic tubes, nozzles, or spark plug insulators.

Understanding the Trade-offs

Production Volume vs. Part Complexity

This is the central trade-off. Wet bag pressing sacrifices speed for the ability to handle high complexity and varied parts. Dry bag pressing sacrifices complexity and flexibility for immense gains in production speed and volume.

Tooling and Setup

Wet bag tooling is generally simpler and less expensive on a per-mold basis. Dry bag systems require a more significant upfront investment in dedicated, automated machinery for a specific part design.

Labor and Automation

The manual loading and unloading of molds make wet bag pressing a labor-intensive process. Dry bag pressing is designed for full automation, dramatically reducing labor costs per part in a mass-production environment.

Final Density

While both methods produce parts with excellent density uniformity, wet bag pressing can achieve slightly higher green densities. This is because there is virtually no friction between the powder-filled mold and the surrounding fluid.

Making the Right Choice for Your Goal

Selecting the appropriate method depends entirely on your production requirements, part geometry, and budget.

- If your primary focus is prototyping or producing complex, large-scale components: Wet bag pressing offers the necessary design flexibility and superior density for specialized, low-volume runs.

- If your primary focus is high-volume, automated manufacturing of simple parts: Dry bag pressing is the clear choice for its high production rate, consistency, and lower cost per unit.

- If your goal is to eliminate residual porosity and achieve full density in a sintered part: Neither CIP method is the final step; you should investigate Hot Isostatic Pressing (HIP) as a subsequent process.

Ultimately, understanding this distinction between flexibility and scalability is the key to leveraging isostatic pressing effectively in your manufacturing process.

Summary Table:

| Feature | Wet Bag Pressing | Dry Bag Pressing |

|---|---|---|

| Primary Use | Prototyping, Complex Shapes, Small Batches | Mass Production, Simple Shapes |

| Automation Level | Low (Manual) | High (Fully Automated) |

| Tooling Flexibility | High (Removable Molds) | Low (Fixed, Integrated Mold) |

| Production Speed | Slow | Fast |

| Ideal For | Versatility and Part Complexity | High Volume and Cost-Efficiency |

Struggling to choose the right isostatic pressing method for your lab's materials? The experts at KINTEK can help you optimize your process. Whether you need the flexibility of wet bag pressing for complex prototypes or the high-volume efficiency of dry bag systems, we provide the precise lab equipment and consumables to meet your specific laboratory needs.

Contact KINTEK today to discuss your project and discover how our solutions can enhance your manufacturing efficiency and part quality.

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the purpose of stainless steel cans in the HIP treatment? Achieve Full Densification of AlFeTiCrZnCu Alloys

- What does hot isostatic pressing do? Eliminate Internal Flaws for Superior Part Performance

- What are the examples of cold working metals? Key Processes for Stronger, Precision Parts

- What is the isostatic pressing method for producing ceramic products? Achieve Uniform, High-Density Ceramic Components

- What is the dry bag process? A Guide to High-Speed Isostatic Pressing

- What is the critical role of a Cold Isostatic Press (CIP)? Enhance LSTH Perovskite Solid Electrolyte Densification

- Why is a Cold Isostatic Press (CIP) Required for NaSICON? Achieve Maximum Green Density and Ionic Conductivity

- What are the advantages of isostatic pressing? Achieve Superior Material Integrity and Design Freedom