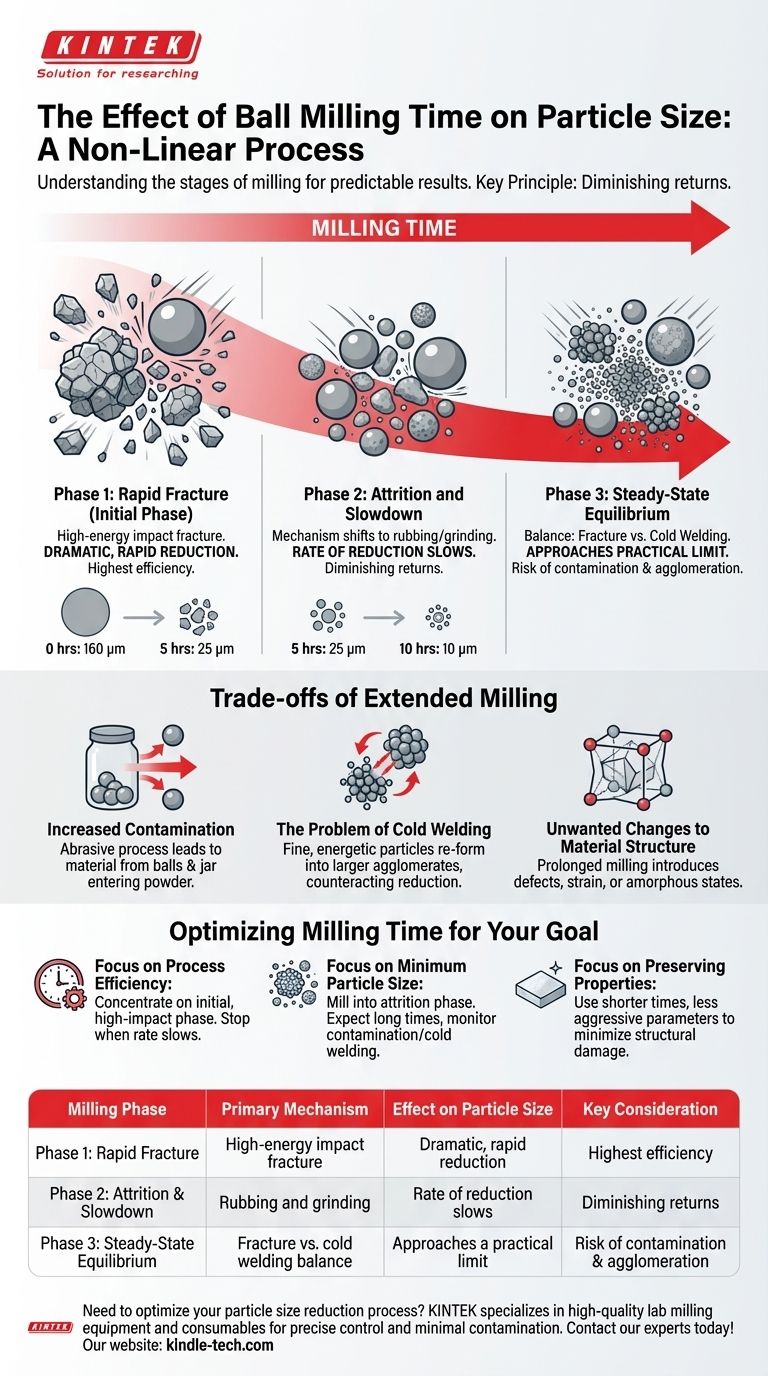

In short, increasing ball milling time progressively reduces particle size, but this effect is not linear. The most dramatic size reduction occurs during the initial phase of milling. As time goes on, the rate of reduction slows significantly until it approaches a practical limit. For instance, an initial 5 hours of milling might reduce a particle from 160 μm down to 25 μm, while the next 5 hours might only reduce it further to 10 μm.

The core principle to understand is that ball milling is a process of diminishing returns. The greatest efficiency is found in the initial hours, after which longer milling times yield progressively smaller gains while introducing potential negative side effects.

The Mechanics of Particle Size Reduction

To control your outcome, you must understand the distinct phases of the milling process. The relationship between time and size is governed by the changing mechanics of how particles interact with the grinding media.

Phase 1: Rapid Fracture

In the beginning, the powder consists of large, often brittle particles. The high-energy impacts from the milling balls easily exceed the particles' fracture strength.

This stage is characterized by rapid and efficient size reduction. Each collision effectively shatters large particles into many smaller ones, as seen in the initial 1-5 hour period where the most significant change occurs.

Phase 2: Attrition and Slowdown

As particles become smaller and more numerous, the nature of the process changes. The energy from a single ball impact is now distributed across many fine particles rather than a few large ones.

The primary mechanism shifts from fracture to attrition (rubbing and grinding). This is a much less efficient method of size reduction, which is why the rate slows down dramatically after the initial phase.

Phase 3: The Steady-State Equilibrium

Eventually, the process reaches a point of equilibrium. The energy supplied by the mill becomes just enough to fracture particles, but the newly created, highly reactive surfaces also begin to re-weld to each other.

This balance between particle fracture and cold welding establishes a practical lower limit on the particle size that can be achieved under specific milling conditions. Milling beyond this point provides little to no further size reduction.

Understanding the Trade-offs of Extended Milling

Simply running the mill for longer is not always the best strategy. It's crucial to be aware of the associated trade-offs that can impact your final material quality.

Increased Contamination

The milling process is inherently abrasive. Longer milling times mean more contact and wear between the grinding media (balls) and the jar walls.

This inevitably leads to increased contamination of your powder with material from the balls and jar. For sensitive applications, this can be a critical disqualifying factor.

The Problem of Cold Welding

As particles become nano-scale, they have a very high surface-area-to-volume ratio and are highly energetic. This makes them prone to agglomerating or sticking together.

Extended milling can exacerbate this cold welding effect, where fine particles re-form into larger agglomerates, counteracting the goal of size reduction.

Unwanted Changes to Material Structure

The intense mechanical energy of milling doesn't just reduce size; it can also alter the material itself.

Prolonged milling can introduce defects, strain, or even change the material's crystal structure, sometimes leading to an amorphous (non-crystalline) state. While this is sometimes desired, it is often an unintended and detrimental side effect.

Optimizing Milling Time for Your Goal

The "correct" milling time is entirely dependent on your objective. Use these principles to guide your process development.

- If your primary focus is process efficiency: Concentrate on the initial, high-impact phase. Stop the process once the rate of size reduction begins to slow significantly to save time and energy.

- If your primary focus is achieving the minimum possible particle size: You must mill into the attrition phase, but be prepared for long process times and diminishing returns. It is critical to monitor for contamination and the onset of cold welding.

- If your primary focus is preserving the material's original properties: Use shorter milling times and less aggressive parameters to minimize structural damage and contamination.

Understanding milling time as a tool to navigate these distinct phases is the key to achieving predictable and repeatable results.

Summary Table:

| Milling Phase | Primary Mechanism | Effect on Particle Size | Key Consideration |

|---|---|---|---|

| Phase 1: Rapid Fracture | High-energy impact fracture | Dramatic, rapid reduction | Highest efficiency |

| Phase 2: Attrition & Slowdown | Rubbing and grinding | Rate of reduction slows | Diminishing returns |

| Phase 3: Steady-State Equilibrium | Fracture vs. cold welding balance | Approaches a practical limit | Risk of contamination & agglomeration |

Need to optimize your particle size reduction process? KINTEK specializes in high-quality lab milling equipment and consumables designed for precise control and minimal contamination. Whether you're focused on efficiency, achieving nano-scale particles, or preserving material integrity, our solutions are tailored to your laboratory's specific needs. Contact our experts today to discuss how we can help you achieve predictable and repeatable milling results!

Visual Guide

Related Products

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the specific role of ball milling equipment in the SIP process? Enhance UHTCMC Infiltration and Homogeneity

- What is the role of a ball mill in UHMWPE/DB composite prep? Achieve High-Energy Uniform Dispersion

- How does the ball mill work? Master the Mechanics of Efficient Grinding and Size Reduction

- How do laboratory ball mills contribute to MOF-confined catalysts? Efficient Green Synthesis for High-Performance R&D

- Why is a planetary ball mill required for sulfide solid electrolytes? Essential Tools for Anode-Free Battery Synthesis

- How does a dry impact-blending device compare to a planetary ball mill? Optimize Your Solid-State Battery Composites

- How does a planetary ball mill contribute to the refinement of LATP glass powder? Optimize Your Material Synthesis

- How does ball milling improve all-solid-state Li-S battery cathodes? Engineering the 3D Transport Network