In magnetron sputtering, chamber pressure is a primary control knob for determining the final quality of your thin film. Lowering the process pressure increases the mean free path of the sputtered atoms, which means they travel from the target to your substrate with fewer gas-phase collisions. This allows them to retain more of their initial energy, resulting in films that are denser, smoother, and have superior adhesion.

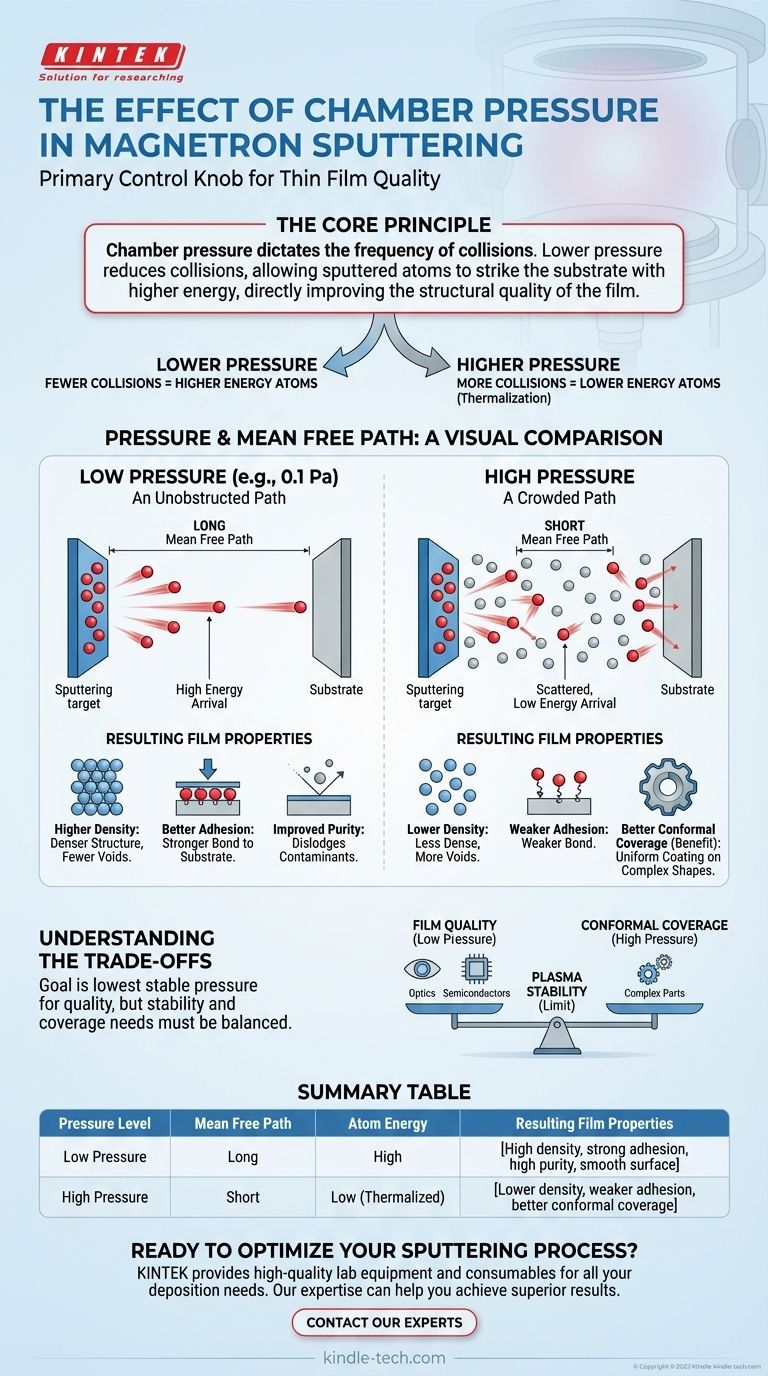

The core principle to understand is that chamber pressure dictates the frequency of collisions. Lower pressure reduces collisions, allowing sputtered atoms to strike the substrate with higher energy, directly improving the structural quality of the film.

The Physics of Pressure: Mean Free Path and Energy

The entire effect of pressure revolves around a single concept: the mean free path. This is the average distance a particle, such as a sputtered atom, can travel before it collides with another particle, like an atom of the inert process gas (e.g., Argon).

At Low Pressure: An Unobstructed Path

When you operate at a lower working pressure (e.g., 0.1 Pa), the chamber contains fewer gas atoms. This significantly increases the mean free path.

Think of it as atoms traveling through a nearly empty hallway. They can move from one end to the other without bumping into anyone, arriving quickly and with all their initial energy.

This high-energy arrival at the substrate surface leads to several desirable film properties:

- Higher Density: The energetic atoms have more mobility on the surface, allowing them to find and fill voids, resulting in a denser film structure.

- Better Adhesion: Higher impact energy can help implant the initial atomic layers into the substrate, creating a stronger bond.

- Improved Purity: A higher-energy deposition process can help dislodge loosely bonded contaminants from the growing film surface.

At High Pressure: A Crowded Path

Conversely, a higher working pressure means the chamber is more crowded with gas atoms. This decreases the mean free path dramatically.

This is like trying to run through a packed concert crowd. The sputtered atoms undergo numerous collisions with gas atoms during their transit.

Each collision robs the sputtered atom of some of its kinetic energy, a process known as thermalization. It also scatters the atom, randomizing its direction. This results in atoms arriving at the substrate with low energy and from many different angles.

Understanding the Trade-offs

While lower pressure generally yields higher-quality films, the choice is not always simple. There are critical trade-offs to consider based on your equipment and deposition goals.

The Clear Benefit of Low Pressure: Film Quality

For applications demanding the highest possible film integrity—such as in optics, semiconductors, or hard coatings—operating at the lowest stable pressure is almost always the goal. The resulting high-energy deposition is the most direct path to superior film density and adhesion.

The Practical Limit: Plasma Stability

The sputtering process requires a stable plasma, which is created by ionizing the inert process gas. If the pressure is too low, there may not be enough gas atoms present to reliably sustain the plasma discharge.

Most systems have a practical lower limit for pressure below which the process becomes unstable or impossible to run. Finding this "sweet spot" of the lowest stable pressure is key.

The Niche Case for High Pressure: Conformal Coverage

In some cases, the scattering effect of high pressure can be beneficial. When coating a complex, three-dimensional object with intricate features, the randomized arrival angles of scattered atoms can help the film deposit more uniformly over all surfaces. This is known as conformal coating.

However, this improved coverage comes at the cost of lower film density and adhesion.

Making the Right Choice for Your Goal

Your optimal chamber pressure is directly tied to the desired outcome for your thin film.

- If your primary focus is achieving maximum film density, purity, and adhesion: Operate at the lowest pressure your system can stably maintain to maximize the energy of the depositing atoms.

- If your primary focus is coating a complex part with non-flat surfaces: You may need to use a slightly higher pressure to induce gas scattering and improve conformal coverage, accepting the trade-off of a less dense film.

- If your primary focus is balancing deposition rate and film quality: You will need to experiment within your system's stable pressure window, as deposition rates can also be affected by pressure and plasma density.

Ultimately, mastering pressure control is fundamental to mastering the magnetron sputtering process itself.

Summary Table:

| Pressure Level | Mean Free Path | Atom Energy | Resulting Film Properties |

|---|---|---|---|

| Low Pressure | Long | High | High density, strong adhesion, high purity, smooth surface |

| High Pressure | Short | Low (Thermalized) | Lower density, weaker adhesion, but better conformal coverage on complex shapes |

Ready to Optimize Your Sputtering Process?

The precise control of chamber pressure is just one factor in achieving perfect thin films. At KINTEK, we specialize in providing high-quality lab equipment and consumables for all your deposition needs. Whether you are developing advanced semiconductors, optical coatings, or hard protective layers, our expertise can help you achieve superior results.

Contact our experts today to discuss how our solutions can enhance your laboratory's capabilities and streamline your research and production workflows.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- How to start a lab-grown diamonds business? Choose Your Path to Success

- What are the structures of molds? Discover the Microscopic Filaments That Build a Colony

- What is argon gas used for? Unlock the Power of Inertness for Welding, Lighting & More

- What are graphite grades? Find the Right Material for Your Industrial Application

- What are the technical requirements for vacuum chambers in desalination? Boost Efficiency with Graphene Technology

- What is the source of energy for pyrolysis? From External Heat to Self-Sustaining Systems

- What are the advantages of pyrolysis plant? Turn Waste into Profit with Advanced Recycling

- What is the science behind sintering? Mastering the Thermal Process for Stronger Materials