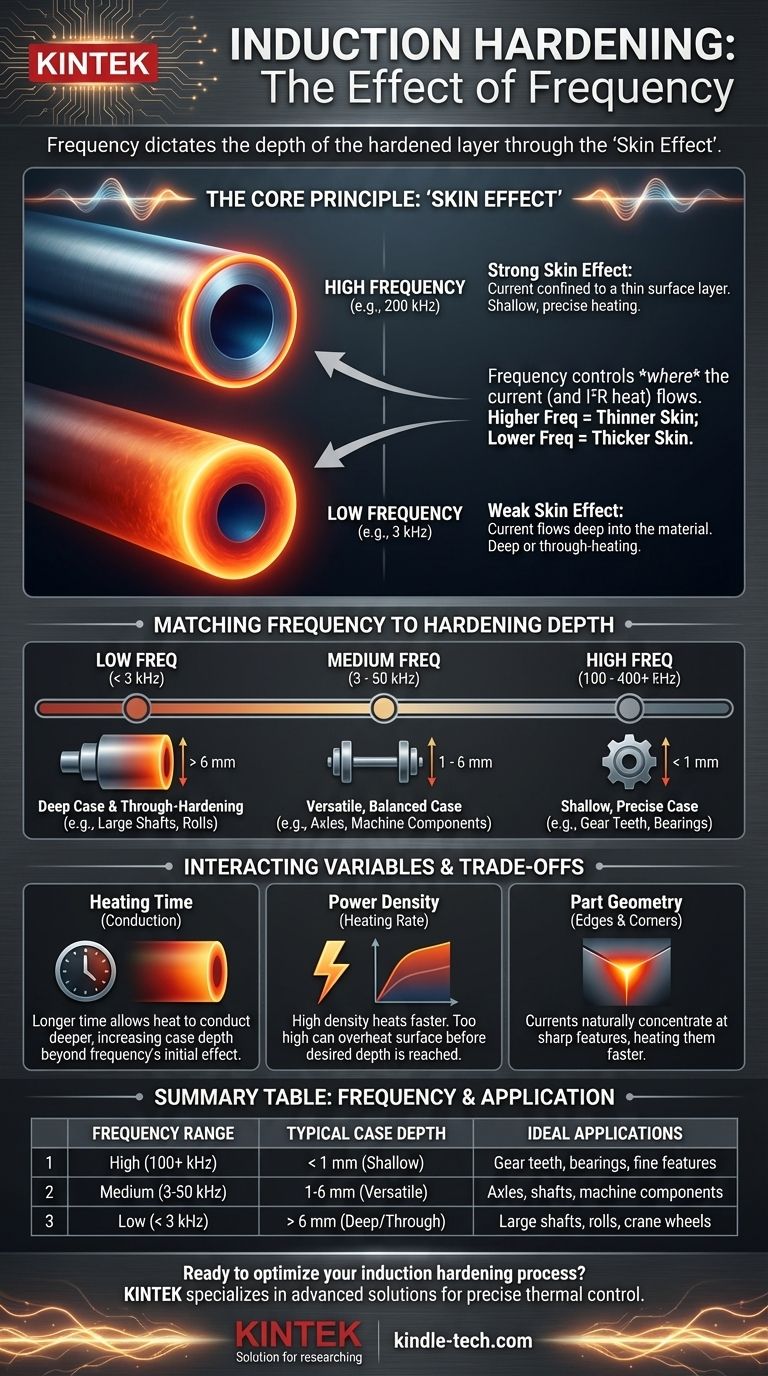

In short, frequency is the primary control for determining the depth of the hardened layer in induction hardening. A higher frequency concentrates the heating effect on the very surface of the part, creating a shallow, hard case. Conversely, a lower frequency allows the heating effect to penetrate deeper into the material, resulting in a much deeper case or even through-hardening.

The core principle to grasp is the "skin effect." The frequency of the alternating current dictates how deep the induced electrical current—and therefore the heat—penetrates the workpiece. This makes frequency the most critical variable for controlling the final case depth of your component.

The Core Principle: Understanding the "Skin Effect"

To understand induction hardening, you must first understand the physics of how alternating current behaves in a conductor. This is governed by a phenomenon known as the skin effect.

What is the Skin Effect?

When an alternating current (AC) flows through a conductor, it doesn't use the entire cross-section uniformly. The current density is highest at the surface and decreases exponentially toward the center.

Essentially, the AC "hugs" the surface, or "skin," of the material. The heat generated by this current is therefore also concentrated at the surface.

How Frequency Controls the Skin Effect

The thickness of this current-carrying skin is directly controlled by the frequency of the AC. The relationship is inverse.

High frequencies (e.g., 200 kHz) cause a very strong skin effect, forcing the current into an extremely thin layer. Low frequencies (e.g., 3 kHz) result in a weak skin effect, allowing the current to flow much deeper into the part.

From Current to Heat

Induction hardening generates heat through electrical resistance (I²R losses). Since the frequency determines where the current flows, it also determines where the heat is initially generated.

This gives you direct, predictable control over the depth of the layer that reaches the critical transformation temperature required for hardening.

Matching Frequency to Hardening Depth

The selection of an operating frequency is not arbitrary; it is a deliberate engineering choice based on the desired metallurgical outcome for a specific part.

High Frequencies (100 kHz - 400 kHz+) for Shallow Cases

High frequencies are used when you need a very hard, thin wear-resistant surface while maintaining a soft, ductile core. The heating is rapid and highly localized.

This is ideal for small parts or parts with fine features, such as gear teeth, saw blades, threads, and bearings, where the required case depth is often less than 1 mm.

Medium Frequencies (3 kHz - 50 kHz) for Versatility

This is the most common range for a wide variety of components. It provides a good balance, creating case depths typically ranging from 1 mm to 6 mm.

Medium frequencies are the workhorse for hardening axles, shafts, and many other machine components that require a substantial hardened layer for both wear resistance and fatigue strength.

Low Frequencies (< 3 kHz) for Deep Cases & Through-Hardening

When a component must withstand extreme torsional or bending loads, a very deep case is required. Low frequencies push the heating effect deep into the material's core.

This range is used for large, heavy-section parts like large-diameter shafts, crane wheels, or rolls. In some cases, the goal is to heat the entire cross-section for through-hardening.

Understanding the Trade-offs and Interacting Variables

Frequency is the most important factor for case depth, but it does not work in isolation. Other process parameters interact with it and must be managed for a successful outcome.

Frequency vs. Heating Time

While a high frequency generates heat in a thin layer, a long heating time will allow that heat to conduct deeper into the part via thermal conduction.

This means you can achieve a slightly deeper case with a higher frequency by simply increasing the heating time. However, using the correct frequency for the target depth is always more efficient and provides better process control.

The Impact of Power Density

Power density (the amount of power applied per unit of surface area) controls the rate of heating. High power density leads to very rapid heating.

Rapid heating can refine the grain structure of the steel, improving toughness. However, if power is too high for the chosen frequency, you risk overheating or even melting the surface before the desired depth is reached.

Considerations for Part Geometry

The induced currents will naturally concentrate at sharp corners, edges, or small radii. These areas will always heat much faster than flat surfaces.

Using too high a frequency on a part with sharp features can cause these areas to overheat and crack before the main body of the part reaches the correct temperature. A lower frequency can sometimes provide more uniform heating on complex geometries.

How to Select the Right Frequency for Your Application

Choosing the correct frequency is a critical step in designing a robust and repeatable induction hardening process. Your decision should be guided by the part's geometry and its final service requirements.

- If your primary focus is a very hard, thin surface layer (< 1 mm) for wear resistance: Use a high frequency (100 kHz+) to precisely control a shallow, localized case.

- If your primary focus is a general-purpose, moderately deep case (1-6 mm) for strength and fatigue life: A medium frequency (3-50 kHz) provides the best balance of depth control and efficiency.

- If your primary focus is deep structural hardening (> 6 mm) or through-hardening of large parts: A low frequency (< 3 kHz) is necessary to drive the heat deep into the core of the material.

By mastering the relationship between frequency and heat penetration, you gain precise control over the final performance of your hardened components.

Summary Table:

| Frequency Range | Typical Case Depth | Ideal Applications |

|---|---|---|

| High (100+ kHz) | < 1 mm (Shallow) | Gear teeth, bearings, fine features |

| Medium (3-50 kHz) | 1-6 mm (Versatile) | Axles, shafts, machine components |

| Low (< 3 kHz) | > 6 mm (Deep/Through) | Large shafts, rolls, crane wheels |

Ready to optimize your induction hardening process? KINTEK specializes in advanced lab equipment and consumables for precise thermal processing. Whether you're working on small components requiring shallow cases or large parts needing deep hardening, our solutions ensure superior control and repeatability. Contact us today to discuss how we can enhance your laboratory's capabilities and achieve your specific hardening goals.

Visual Guide

Related Products

- Automatic Laboratory Heat Press Machine

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Three-dimensional electromagnetic sieving instrument

- Double Plate Heating Press Mold for Lab

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- Why is a laboratory hot press required for Oxygen Depolarized Cathodes? Ensure Precision Molding and Conductivity.

- Why is a laboratory hot press necessary for the production of plastic crystal polymer electrolyte reinforced membranes?

- What role does a laboratory plate hot press play in the vulcanization and molding of fluorosilicone rubber (F-LSR)?

- Why is a laboratory precision hot press necessary for processing high-performance composite solid-state electrolyte membranes?

- What are the advantages of using a hot press for Li7P2S8I0.5Cl0.5? Boost Conductivity with Precision Densification