High-speed sintering dramatically accelerates the transformation of zirconia from a porous, chalk-like state into a dense, high-strength ceramic. The primary effect is achieving the necessary material densification and strength in a fraction of the time required by conventional methods, typically reducing a process of several hours to under an hour. This is accomplished through very rapid heating and cooling cycles.

The core effect of high-speed sintering is a significant reduction in processing time. However, this speed introduces a critical trade-off: the process must be precisely controlled to ensure uniform heating and cooling, which is essential for achieving the same density, strength, and structural integrity as traditional, slower methods.

The Goal of Sintering: From Powder to Solid

Sintering is the fundamental process that gives zirconia its final, robust properties. Understanding the conventional process is key to grasping the effects of accelerating it.

What is Sintering?

Sintering is a thermal treatment that fuses ceramic particles into a solid, coherent mass. This is achieved by applying heat below the material's melting point, causing the individual grains to bond together.

This critical step is what transforms the pre-sintered, "green state" zirconia into a functional, load-bearing material. The final mechanical properties are almost entirely dictated by the success of this stage.

The Role of Microscopic Changes

At a microscopic level, sintering is driven by reducing the surface energy of fine powder particles. The high surface area of these small particles creates a powerful incentive for them to bond, reducing the overall energy of the system.

During this process, atoms diffuse across the boundaries of the particles, filling the voids (pores) between them. This material transfer is what causes the object to become denser and stronger.

Key Outcomes: Density and Shrinkage

The most visible effect of sintering is significant shrinkage, as the space once occupied by pores is eliminated.

This reduction in porosity directly leads to an increase in density. A properly sintered zirconia part will have very few internal voids, which is essential for its high mechanical strength and fracture resistance.

The Impact of High-Speed Cycles

High-speed sintering aims to achieve the same endpoint as conventional sintering but on a much shorter timeline. This acceleration has direct consequences on the material.

The Time Factor

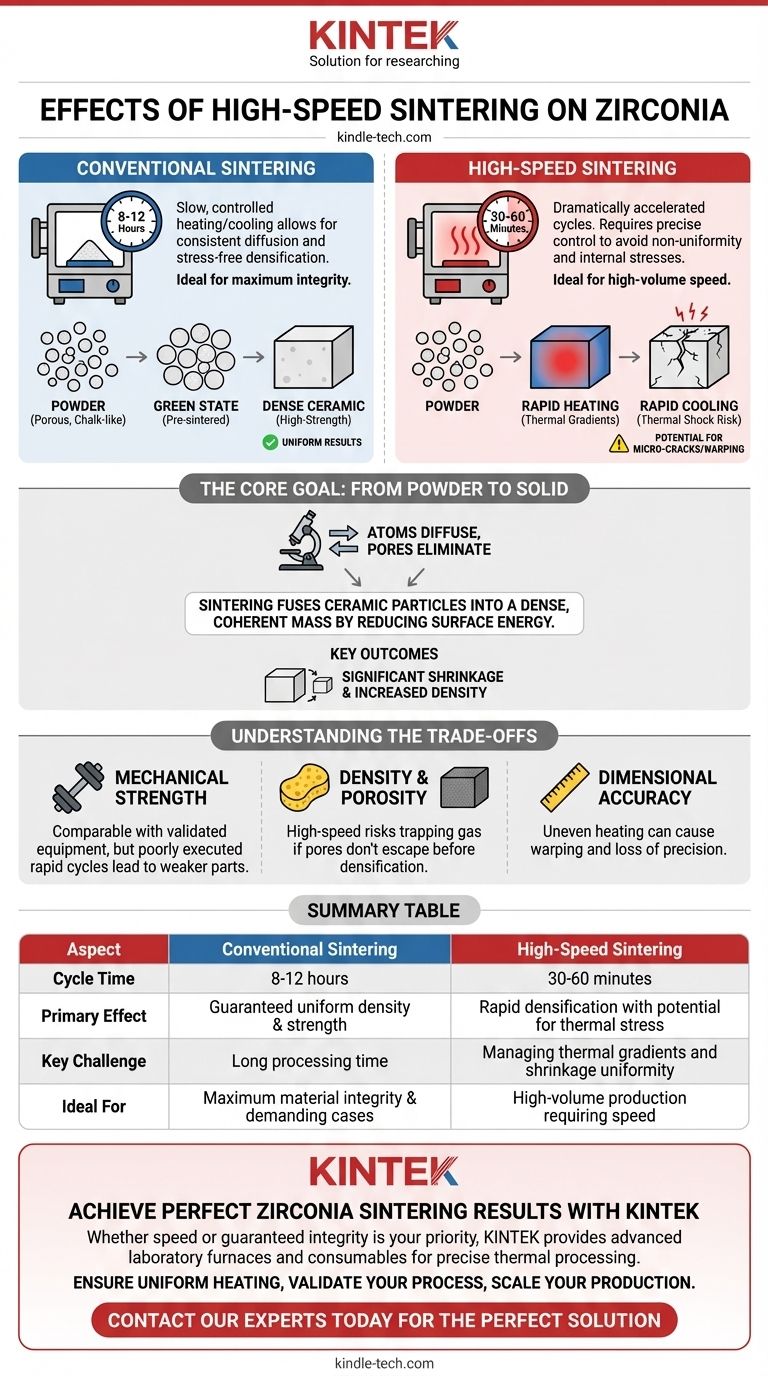

The most significant effect is the dramatic reduction in cycle time. A conventional sintering process can take 8-12 hours, while a high-speed cycle can be completed in as little as 30-60 minutes. This provides a massive efficiency gain in production environments like dental labs.

The Challenge of Rapid Heating

To achieve this speed, the furnace must heat the zirconia very quickly. If not managed perfectly, this can create a significant temperature difference between the surface and the core of the material.

This thermal gradient can lead to incomplete sintering in the center, resulting in a weaker, less dense final product.

The Risk of Thermal Shock

Just as important is the cooling phase. Rapid cooling can introduce internal stresses into the ceramic structure.

In extreme cases, this can lead to thermal shock, causing micro-cracks that compromise the material's long-term durability and structural integrity, even if they aren't visible.

Understanding the Trade-offs of Speed

While high-speed sintering is effective, it is not without compromises. The success of the process depends entirely on the quality of the equipment and the specific formulation of the zirconia material.

Mechanical Strength

When performed correctly with validated equipment and materials, high-speed sintering can produce zirconia with mechanical strength comparable to that achieved through conventional methods. However, a poorly executed rapid cycle is far more likely to result in a weaker part than a poor conventional cycle.

Density and Porosity

The primary goal of eliminating porosity remains the same. The challenge with high-speed cycles is allowing enough time for gas trapped in pores to escape before the material fully densifies around them. Modern, high-quality zirconia blocks are formulated to facilitate this rapid densification.

Dimensional Accuracy

Shrinkage is an inevitable and calculated part of the process. The main risk with high-speed sintering is non-uniform shrinkage due to uneven heating. This can lead to warping or a loss of precision, which is a critical failure for applications requiring exact dimensions, like dental crowns or bridges.

Making the Right Choice for Your Application

Choosing the appropriate sintering method depends on balancing the need for speed with the demand for material quality and consistency.

- If your primary focus is maximum production speed: High-speed sintering is the clear choice, but you must use a furnace and zirconia materials that have been specifically designed and validated to work together for these rapid cycles.

- If your primary focus is absolute material integrity for the most demanding cases: Conventional, slow sintering remains the gold standard for guaranteeing uniform, stress-free results, although the gap in quality is narrowing with modern technology.

- If you are experiencing inconsistent results like chipping or fractures: Your first step should be to verify that your furnace's high-speed cycle is perfectly calibrated and that the zirconia you are using is explicitly approved for that cycle by the manufacturer.

Ultimately, successful high-speed sintering relies on a precisely controlled system where the material, equipment, and process are validated to work in harmony.

Summary Table:

| Aspect | Conventional Sintering | High-Speed Sintering |

|---|---|---|

| Cycle Time | 8-12 hours | 30-60 minutes |

| Primary Effect | Guaranteed uniform density & strength | Rapid densification with potential for thermal stress |

| Key Challenge | Long processing time | Managing thermal gradients and shrinkage uniformity |

| Ideal For | Maximum material integrity & demanding cases | High-volume production requiring speed |

Achieve Perfect Zirconia Sintering Results with KINTEK

Whether your lab prioritizes the speed of high-speed sintering or the guaranteed integrity of conventional cycles, the right equipment is critical. KINTEK specializes in advanced laboratory furnaces and consumables designed for precise thermal processing.

We provide solutions that help dental labs and material scientists:

- Ensure Uniform Heating: Prevent internal stresses and micro-cracks with precisely controlled furnaces.

- Validate Your Process: Use equipment and materials validated to work in harmony for consistent, high-strength results.

- Scale Your Production: Increase throughput without sacrificing the final quality of your zirconia components.

Don't let sintering challenges limit your lab's potential. Contact our experts today via our form to find the perfect sintering solution for your specific zirconia materials and application requirements.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Spark Plasma Sintering Furnace SPS Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What makes zirconia translucent? The Science Behind Modern Dental Aesthetics

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag

- What are the white spots on zirconia after sintering? A Guide to Diagnosing and Preventing Defects