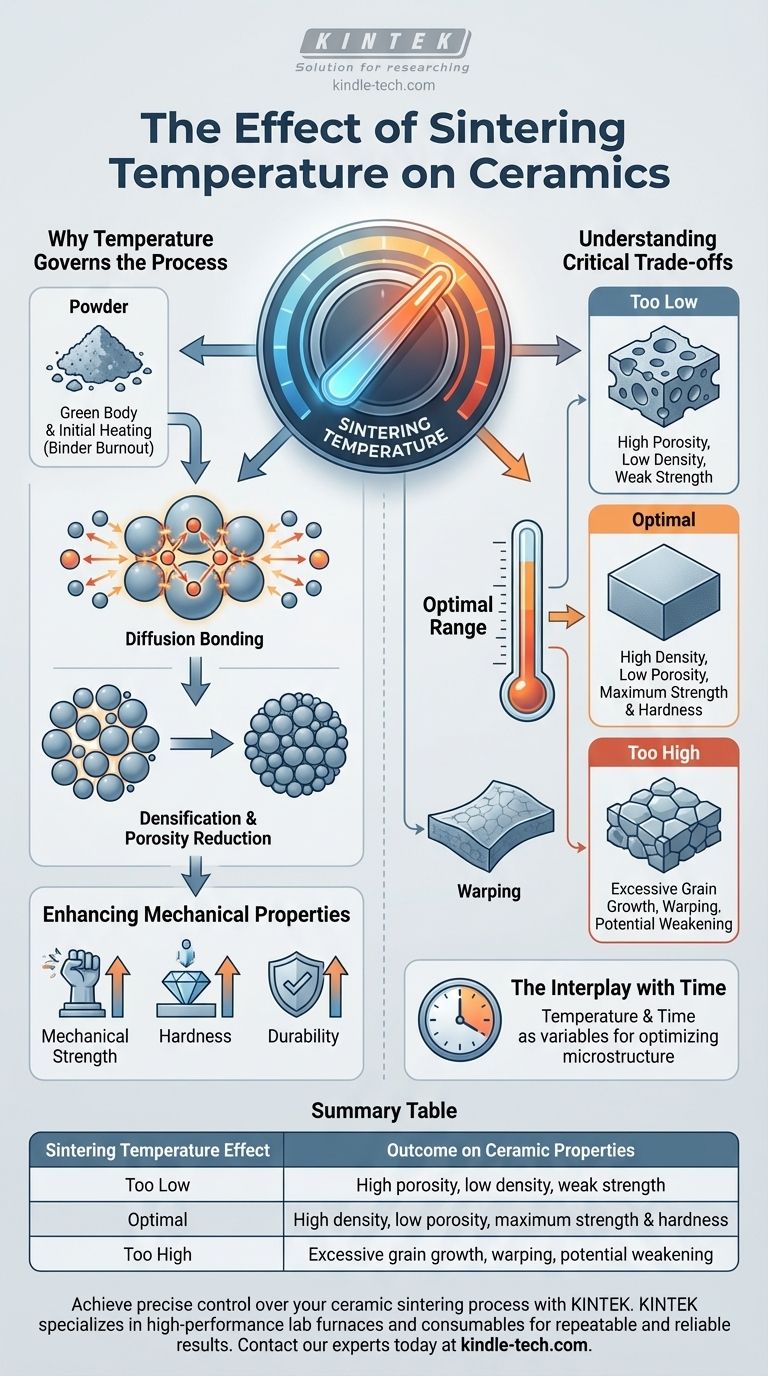

Sintering temperature is the primary control lever for determining the final properties of a ceramic component. It directly governs the transformation of loose powder into a dense, solid material, critically affecting its final density, porosity, strength, and hardness. The correct temperature creates a strong, durable part, while incorrect temperatures can result in a weak, porous product or even a warped, unusable defect.

The core function of sintering temperature is to provide the thermal energy necessary for atoms to diffuse between powder particles. This atomic movement eliminates the voids between particles, increasing the material's density and strength. The central challenge is finding the precise temperature that maximizes this densification without causing negative effects like excessive grain growth or physical distortion.

Why Temperature Governs the Sintering Process

Sintering is fundamentally a process of thermal transformation. Temperature isn't just a setting; it's the energy that drives the entire physical change from a fragile powder compact (a "green body") into a robust polycrystalline ceramic.

The Mechanism: From Powder to Solid

At lower temperatures during the initial heating phase, any residual organic binders used to shape the part are burned away.

As the temperature rises significantly, it energizes the atoms within the ceramic powder. This energy allows them to move and bond with atoms from adjacent particles at their points of contact, a process known as diffusion bonding.

Driving Densification and Reducing Porosity

This atomic diffusion is the engine of densification. As particles bond, the contact area between them grows, pulling the centers of the particles closer together.

This action systematically closes the gaps and channels (pores) that existed in the initial powder compact. The result is a significant reduction in porosity and a corresponding increase in density, causing the entire component to shrink.

Enhancing Mechanical Properties

The final physical properties of the ceramic are a direct consequence of this densification process.

A well-sintered part with low porosity and high density will exhibit superior mechanical strength, hardness, and durability. In contrast, a part with high residual porosity will be mechanically weak and prone to failure.

Understanding the Critical Trade-offs

The ideal sintering temperature is not simply the highest possible heat. It is a carefully optimized point within a specific range, where positive outcomes are maximized and negative effects are avoided.

The Risk of Insufficient Temperature

If the sintering temperature is too low, there isn't enough thermal energy to drive sufficient atomic diffusion.

This results in an under-sintered part. The ceramic will retain high porosity, exhibit low density, and possess poor mechanical properties, rendering it fragile and ineffective for its intended application.

The Danger of Excessive Temperature

Conversely, if the temperature is too high or held for too long, new problems emerge. The process can lead to rapid and uncontrolled grain growth, where smaller grains merge into larger ones, which can surprisingly weaken the final material.

Extreme heat can also cause the component to warp, slump, or even partially melt, a defect sometimes referred to as scorching. This destroys the part's dimensional accuracy and structural integrity.

The Interplay with Time

Sintering is a function of both temperature and time. A slightly lower temperature for a longer duration can sometimes achieve a similar level of densification as a higher temperature for a shorter time. Optimizing both variables is key to achieving a uniform and stable microstructure.

Making the Right Choice for Your Goal

The optimal sintering temperature is entirely dependent on the specific ceramic material and the desired properties of the final component. Your target determines your strategy.

- If your primary focus is maximum density and strength: You must operate near the upper limit of the material's sintering window, carefully controlling the temperature profile to achieve full densification without overheating.

- If your primary focus is maintaining a fine-grained microstructure: You may need to use a slightly lower temperature for a longer duration or employ advanced techniques like pressure-assisted sintering to limit grain growth.

- If your primary focus is dimensional accuracy: You must precisely control the entire thermal cycle—heating rate, hold time, and cooling rate—to ensure shrinkage is uniform and predictable, thus preventing warpage.

Ultimately, mastering sintering temperature is the key to transforming a simple powder into a high-performance ceramic component engineered for its purpose.

Summary Table:

| Sintering Temperature Effect | Outcome on Ceramic Properties |

|---|---|

| Too Low | High porosity, low density, weak strength |

| Optimal | High density, low porosity, maximum strength & hardness |

| Too High | Excessive grain growth, warping, potential weakening |

Achieve precise control over your ceramic sintering process with KINTEK.

Whether you're developing advanced ceramics for maximum strength or require fine-grained microstructures for specific applications, the right laboratory equipment is critical. KINTEK specializes in high-performance lab furnaces and consumables that deliver the exact, uniform heating necessary for repeatable and reliable results.

Contact our experts today to discuss your ceramic sintering requirements. Let us help you select the ideal equipment to optimize density, enhance mechanical properties, and ensure the success of your materials development.

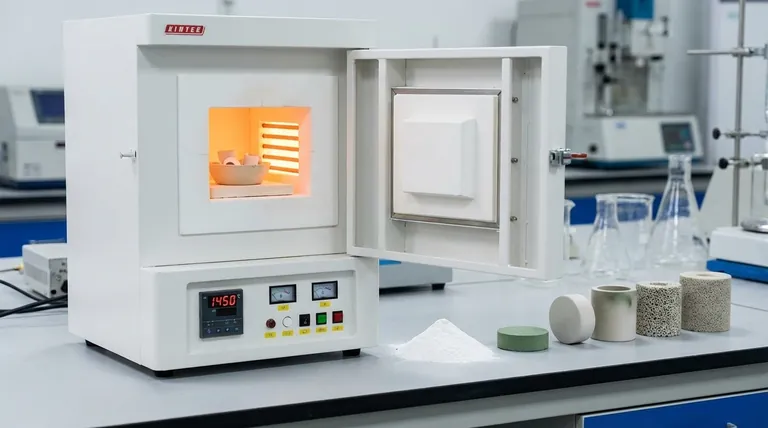

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

People Also Ask

- What specific conditions do high-temperature test furnaces provide for evaluating the corrosion resistance of C/C-SiC composites?

- What is the primary function of a box furnace for Inconel 625? Mastering Heat Treatment and Microstructural Control

- What is the muffle furnace 1800 degree? High-Temp Precision for Advanced Materials

- Why is precise heating rate control critical for tungsten oxide annealing? Preserve Delicate Nanostructures

- What is the function of an external heating high-temperature furnace in SCWG? Optimize Your Biomass Gasification Research

- What is the function of industrial box resistance furnaces in 3D printing post-processing? Optimize Metal AM Parts

- Why is a muffle furnace or oven used for calcining quartz wafer substrates at 500°C? Achieve Perfect Catalyst Adhesion

- What is the primary function of a high-temperature furnace in KIT-6 preparation? Unlock Mesoporous Silica Potential