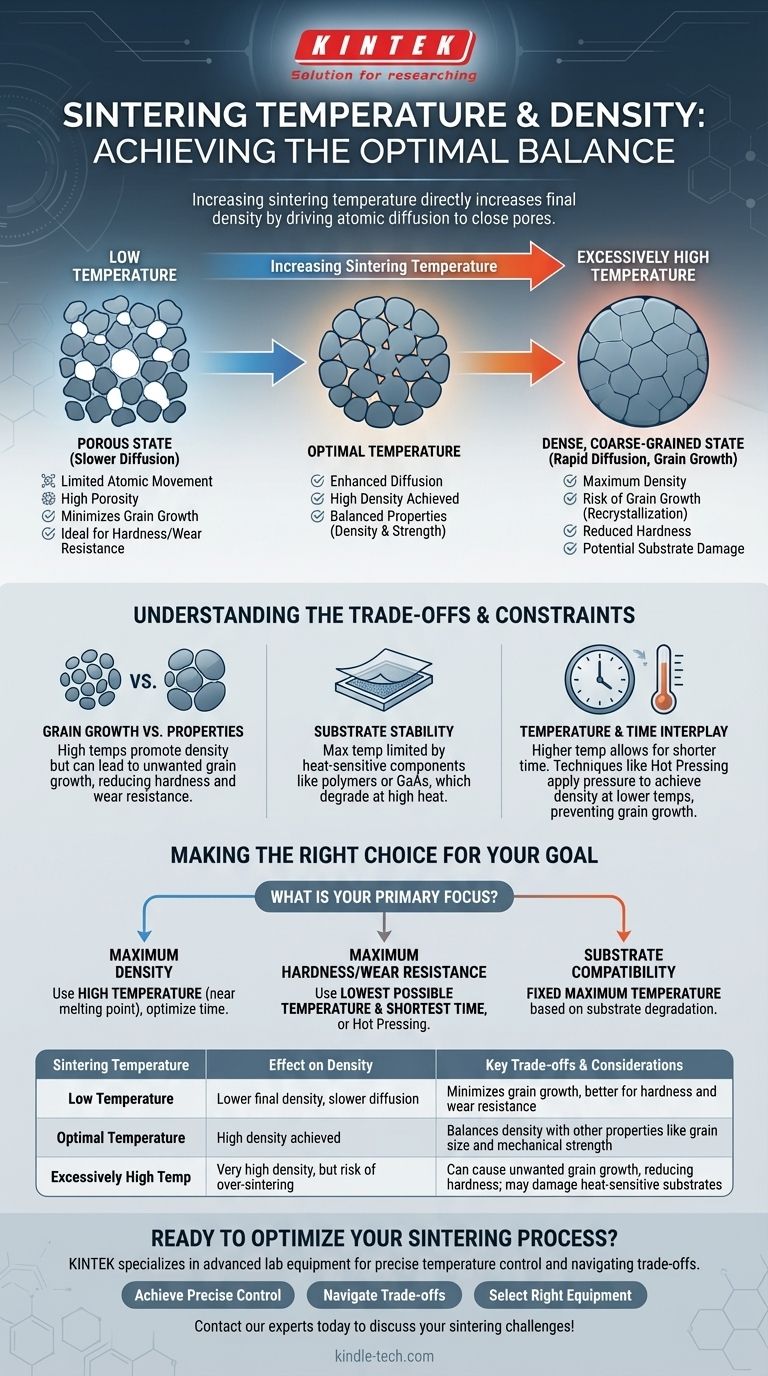

In principle, increasing the sintering temperature directly increases the final density of a material. This occurs because higher temperatures provide the thermal energy needed to drive diffusion, the atomic-level process that closes the pores between initial particles and fuses them into a solid mass. The goal is often to reach a density that is as close as possible to the material's theoretical maximum.

While higher temperatures promote higher density, the central challenge is not simply maximizing temperature. It is about finding the optimal thermal point that achieves the desired density without sacrificing other critical material properties or violating system constraints.

The Fundamental Role of Temperature in Sintering

Sintering is fundamentally a process of reducing a material's surface energy by bonding particles together. Temperature is the primary catalyst for this transformation.

Driving Atomic Diffusion

Atoms within a solid are not static. Temperature provides the kinetic energy that allows them to move, or diffuse. During sintering, this diffusion allows material to move from the bulk of the particles to the necks forming between them, and to fill the voids or pores left from the initial packing.

This process relies on mechanisms like bulk diffusion (atoms moving through the particle) and grain boundary diffusion (atoms moving along the interface between particles). Both are heavily dependent on temperature; a higher temperature means exponentially faster diffusion and, therefore, faster densification.

Reducing Porosity to Increase Density

The direct result of atomic diffusion is the gradual elimination of pores within the material. As these voids shrink and close, the overall volume of the component decreases, and its density increases.

For many high-performance applications, the objective is to achieve a density greater than 99% of the material's theoretical maximum, creating a product with extremely low porosity.

Understanding the Trade-offs of Higher Temperatures

Simply increasing the temperature indefinitely is not a viable strategy. There are critical trade-offs and constraints that dictate the practical temperature limits for any given process.

The Risk of Unwanted Grain Growth

While a high temperature promotes densification, if held for too long it can also lead to recrystallization, or grain growth. This is a process where smaller crystal grains merge to form larger ones.

For many applications, this is undesirable. Finer grains often result in superior mechanical properties, such as higher hardness and wear resistance. A key goal of a well-controlled sintering process is to achieve full density while preventing or minimizing this grain growth.

Process Constraints and Substrate Stability

The maximum allowable temperature is often dictated by the components of the system, not just the material being sintered. Many advanced applications involve depositing films onto substrates that cannot withstand high heat.

For example, flexible electronics built on polymeric substrates or devices using compound semiconductors like Gallium Arsenide (GaAs) will degrade or be destroyed at the high temperatures required for traditional ceramic sintering.

The Interplay of Temperature and Time

Temperature does not act in isolation; its effect is coupled with processing time. A shorter duration at a very high temperature can achieve a similar density to a longer duration at a lower temperature.

Specialized techniques like hot pressing leverage this relationship. By applying external pressure alongside heat, densification can be achieved more quickly and at a lower temperature, which is highly effective at preventing grain growth and producing fine-grained, high-hardness parts.

Making the Right Choice for Your Goal

Selecting the correct sintering temperature is a balancing act between achieving density and meeting other performance and system requirements.

- If your primary focus is achieving maximum possible density: You will need to use a high temperature, approaching the material's melting point, while carefully optimizing the time to minimize excessive grain growth.

- If your primary focus is maximizing hardness and wear resistance: You should use the lowest possible temperature and shortest time that achieves your target density, or consider advanced methods like hot pressing to preserve a fine grain structure.

- If your primary focus is compatibility with a heat-sensitive substrate: Your maximum temperature is fixed by the substrate's degradation point, and you must work within that thermal budget, potentially exploring alternative low-temperature consolidation methods.

Ultimately, mastering the effect of temperature empowers you to precisely control the final properties of your material.

Summary Table:

| Sintering Temperature | Effect on Density | Key Trade-offs & Considerations |

|---|---|---|

| Low Temperature | Lower final density, slower diffusion | Minimizes grain growth, better for hardness and wear resistance |

| Optimal Temperature | High density achieved | Balances density with other properties like grain size and mechanical strength |

| Excessively High Temperature | Very high density, but risk of over-sintering | Can cause unwanted grain growth, reducing hardness; may damage heat-sensitive substrates |

Ready to optimize your sintering process for maximum density and performance?

KINTEK specializes in providing advanced lab equipment and consumables for materials research and development. Whether you are working with ceramics, metals, or composites, our expertise can help you:

- Achieve precise temperature control for consistent, high-density results.

- Navigate the trade-offs between density, grain growth, and mechanical properties.

- Select the right equipment for your specific material and substrate requirements.

Let our solutions enhance your lab's capabilities. Contact our experts today to discuss your sintering challenges and goals!

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What are the physical properties of nitrogen gas? A Guide to Its Power and Invisible Dangers

- What is the future scope of pyrolysis oil? A Key Feedstock for Sustainable Fuels and Chemicals

- What are some challenges of using waste biomass for energy? Navigating Logistics, Cost, and Efficiency Hurdles

- What equation do you use to calculate the heat required to melt a sample? Master the Heat of Fusion Formula

- What is the function of temperature control during the drying stage of the biomass gasification process? Optimize Yield

- Which is better carbon or graphite? Choose the Right Material for Your Application

- Are biomass fuels sustainable? Uncover the truth behind carbon neutrality and lifecycle impacts.

- What is the primary function of a vacuum pump? Remove Gas Molecules to Create a Controlled Vacuum