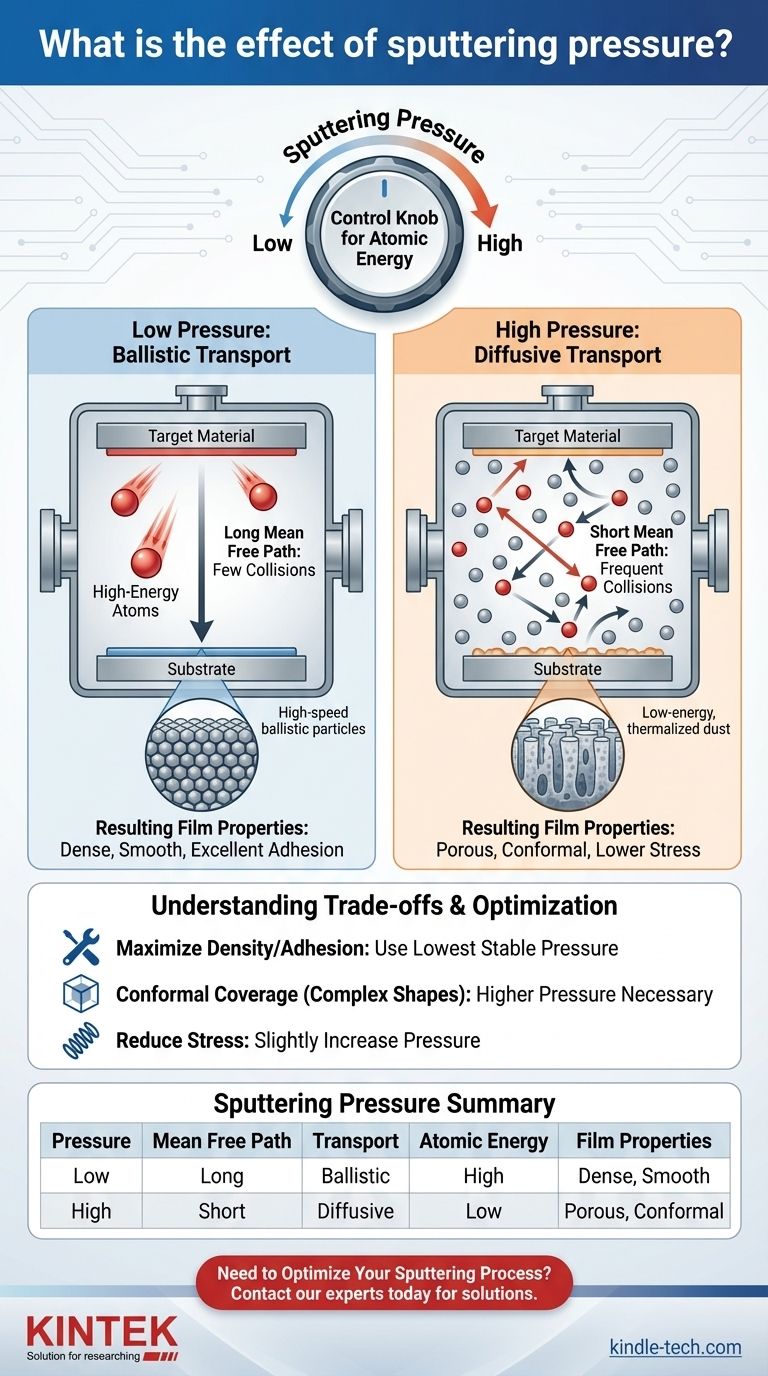

Sputtering pressure is the single most important parameter for controlling the energy of atoms as they deposit onto your substrate. In short, the gas pressure in your vacuum chamber dictates the frequency of collisions between sputtered atoms and background gas atoms. Lower pressure reduces collisions, resulting in high-energy deposition and denser films, while higher pressure increases collisions, leading to low-energy deposition and more porous films.

The core principle to understand is that sputtering pressure acts as a control knob for atomic energy. By adjusting the pressure, you are deciding whether atoms arrive at your substrate like high-speed ballistic particles or like low-energy, thermalized dust. This choice directly determines the final density, adhesion, stress, and structure of your thin film.

The Physics of Pressure: Mean Free Path and Collisions

What is Sputtering Pressure?

Sputtering pressure refers to the quantity of inert gas, typically argon, maintained within the vacuum chamber during the deposition process.

It is not a measure of the plasma's force, but rather the density of gas atoms available to sustain the plasma and interact with the sputtered material.

The Concept of Mean Free Path

The mean free path is the most critical concept to grasp. It defines the average distance a particle—in this case, a sputtered atom—can travel before it collides with another particle, such as an argon gas atom.

Think of it as the "personal space" for each atom. More space means fewer interruptions.

How Pressure Dictates Mean Free Path

A low sputtering pressure means there are fewer gas atoms in the chamber. This creates a long mean free path, allowing sputtered atoms to travel a significant distance without collision.

Conversely, a high sputtering pressure means the chamber is more crowded with gas atoms. This creates a very short mean free path, causing sputtered atoms to collide many times before reaching the substrate.

The Impact of Low Sputtering Pressure

Ballistic Transport

At low pressures, the long mean free path allows sputtered atoms to travel directly from the target to the substrate with few or no collisions. This is called ballistic transport.

These atoms retain a large portion of the high initial energy they received when they were ejected from the target material.

Resulting Film Properties: Dense and Adherent

When these high-energy atoms strike the substrate, they act like tiny hammers, physically packing themselves into a dense, tightly-bound structure.

This energetic bombardment displaces loosely bound atoms, fills voids, and promotes strong bonding with the substrate, resulting in a film with high density and excellent adhesion.

Smoother Surfaces

The high kinetic energy of the arriving atoms also gives them more surface mobility. They can move around on the substrate surface to find the most stable, low-energy positions, leading to a smoother and more uniform film.

The Impact of High Sputtering Pressure

Diffusive Transport

At high pressures, the short mean free path forces sputtered atoms into a series of collisions with the background gas. This process is called diffusive transport or a "random walk."

With each collision, the sputtered atom loses energy and changes direction. It effectively drifts toward the substrate rather than flying directly to it.

Resulting Film Properties: Porous and Less Stressed

These low-energy, or thermalized, atoms arrive at the substrate gently, like snowflakes settling on the ground. They have little energy to rearrange themselves, leading to a more columnar, less dense, and often porous film structure.

While often less desirable, this gentle deposition can be beneficial for reducing the intrinsic compressive stress that is common in sputtered films.

Conformal Coating Benefits

The random, multi-directional arrival of thermalized atoms can be a significant advantage when coating complex, three-dimensional shapes.

Because atoms arrive from many angles, a high-pressure process can produce a more conformal coating that covers sidewalls and steps more uniformly than a line-of-sight low-pressure process.

Understanding the Trade-offs

Why Not Always Use the Lowest Pressure?

While low pressure often produces the highest quality films, there are limits. If the pressure is too low, it can become difficult to ignite or sustain a stable plasma, leading to an unstable process.

Furthermore, the high energy associated with low-pressure deposition can create very high compressive stress in some materials, which may cause the film to peel or crack.

High Pressure for Complex Geometries

The primary reason to deliberately use higher pressure is for conformal coverage. If you need to coat the inside of a trench or a non-flat surface, the diffusive transport at high pressure is essential. The trade-off is a less dense film.

Pressure vs. Plasma and Ionization

Sputtering pressure also influences the plasma itself. Higher pressures generally lead to a denser plasma but reduce the energy of the ions bombarding the target. This creates a complex interplay that affects the overall deposition rate and process stability.

Optimizing Pressure for Your Goal

By understanding the direct link between pressure, atomic energy, and film structure, you can select the right conditions for your specific application.

- If your primary focus is maximum film density, adhesion, and smoothness: Use the lowest process pressure that allows for a stable plasma.

- If your primary focus is coating a complex, 3D surface uniformly: A higher pressure is likely necessary to promote diffusive transport and achieve conformal coverage.

- If your primary focus is reducing high compressive film stress: Experiment with slightly increasing the pressure to lower the energy of depositing atoms.

By mastering pressure as a tool to control atomic energy, you can precisely engineer the properties of your thin films to meet any requirement.

Summary Table:

| Sputtering Pressure | Mean Free Path | Transport Type | Atomic Energy | Resulting Film Properties |

|---|---|---|---|---|

| Low Pressure | Long | Ballistic | High | Dense, smooth, excellent adhesion |

| High Pressure | Short | Diffusive | Low (Thermalized) | Porous, conformal, lower stress |

Need to Optimize Your Sputtering Process?

Mastering sputtering pressure is key to achieving the precise film properties your research or production requires. Whether you need high-density coatings for superior performance or conformal films for complex 3D structures, KINTEK's expertise in lab equipment and consumables can help.

We specialize in providing solutions for laboratory thin-film deposition, offering the right tools and consumables to control every parameter perfectly.

Contact our experts today to discuss how we can help you engineer the perfect thin films for your specific application.

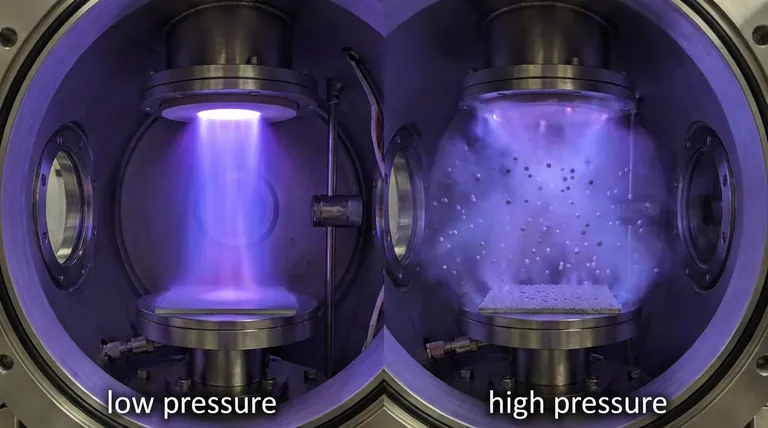

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

People Also Ask

- What is the difference between wiped film and thin film? Unlock the Right Distillation Method for Your Process

- How do you evaporate ethyl acetate? Master Safe & Efficient Solvent Removal with Rotary Evaporation

- What is the thermal stability of graphene? A Guide to Temperature Limits and Material Selection

- What is the advantage of sintered glass filter? Achieve Superior Purity and Precision in Your Lab Filtration

- Why KBr is used for FTIR? Achieve Clear, Accurate Solid-Sample Analysis

- How do precision dripping systems or syringes contribute to sodium alginate bead formation? Achieve Scientific Uniformity

- Which of the following property is affected by heat treatment? A Guide to Tailoring Material Performance

- How do you heat treat aluminium castings? A 3-Step Guide to Boost Strength & Durability