The efficiency of a rotary kiln is not a single, fixed number. Instead, it is a dynamic outcome determined by a precise combination of design choices and operational parameters. The key factors influencing its performance include the kiln’s temperature profile, rotation speed, inclination angle, and the rate at which material is fed and discharged.

A rotary kiln’s efficiency is best understood not as a static rating, but as a measure of how effectively it balances heat transfer, material residence time, and energy containment for a specific thermal process. Achieving high efficiency is a function of tailored engineering and disciplined operational control.

How a Rotary Kiln Achieves Its Goal

A rotary kiln is fundamentally a sophisticated heat exchanger designed to process solid materials at extremely high temperatures. Its purpose is to induce a physical change or chemical reaction, such as drying, calcination, or sintering.

The Core Function: A Cascading Heat Exchanger

The heart of the system is the long, cylindrical rotating shell, which is slightly inclined. As the kiln rotates, the material inside is continuously lifted by the kiln's rotation and cascades down, mixing thoroughly.

This tumbling action maximizes the material's exposure to the hot gases and radiant heat, ensuring uniform and efficient heat transfer throughout the bed of material.

Key Mechanical Components and Their Role

Several components are critical to this function. The shell provides the structure, while the refractory lining inside is essential for containing the intense heat, protecting the shell, and minimizing thermal loss to the environment.

Support tyres (riding rings) and rollers allow the massive shell to rotate smoothly, while the drive gear controls the rotational speed. The entire system is engineered to handle the specific material being processed.

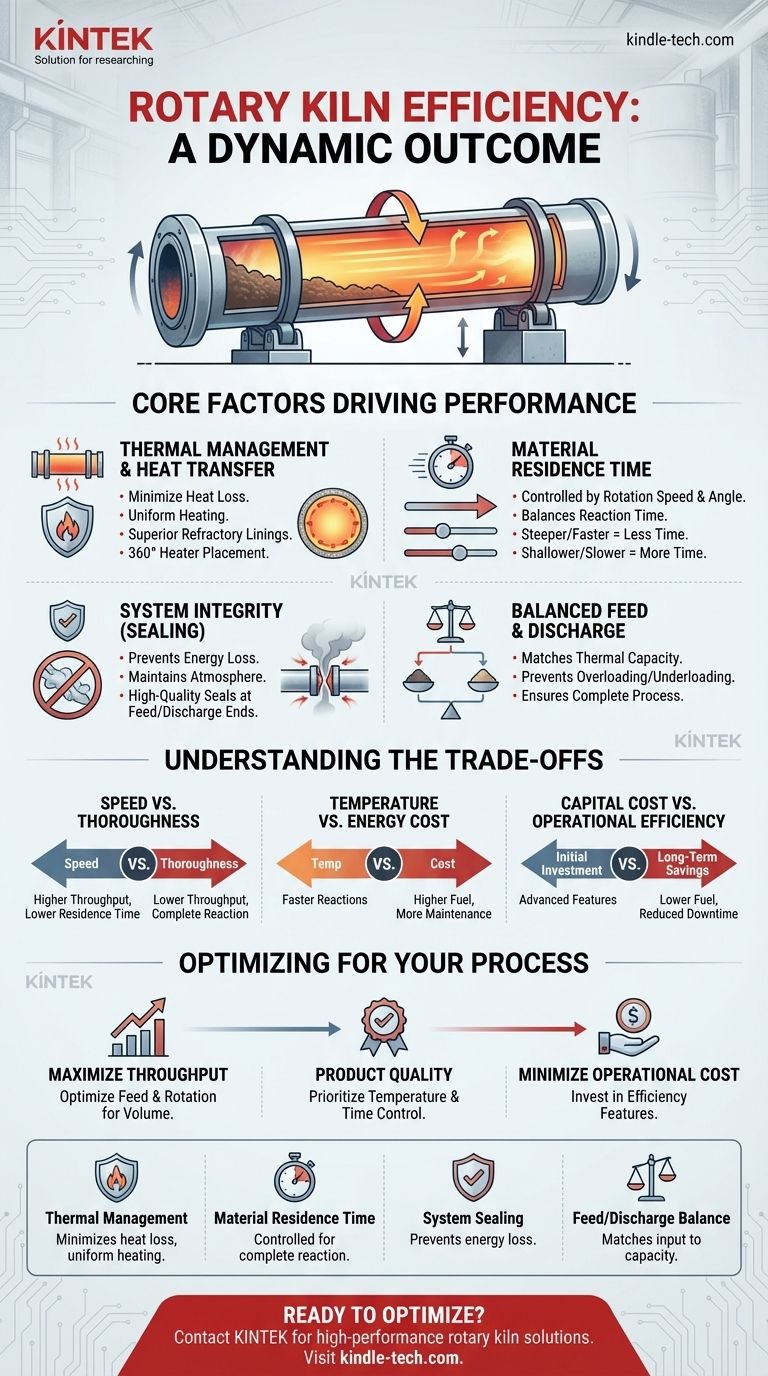

The Core Factors Driving Efficiency

True efficiency is a result of several interconnected variables working in harmony. Optimizing one factor often impacts the others, requiring a holistic approach to design and operation.

Thermal Management and Heat Transfer

The most efficient kilns feature superior refractory linings to minimize heat loss through the shell. Modern designs often use 360° heater placement to ensure even heat transmission directly to the material bed, preventing hot spots and wasted energy.

Material Residence Time

The amount of time the material spends inside the kiln is critical. This is controlled by two main parameters: the inclination angle of the kiln and its rotation speed. A steeper angle or faster rotation reduces residence time, while a shallower angle or slower rotation increases it. Efficiency is achieved when the residence time is just long enough for the desired reaction to complete, but no longer.

Sealing and System Integrity

Any uncontrolled air leaking into the kiln or hot gas leaking out represents a significant energy loss. High-quality seals at the feed and discharge ends are crucial for maintaining airtightness, ensuring a stable internal atmosphere, and preventing heat from escaping the system.

Balanced Feed and Discharge

The rate at which raw material is fed into the kiln must be matched to its thermal capacity. Overloading the kiln prevents material from reaching the target temperature, leading to an incomplete process and inefficiency. Under-loading it means heat is wasted on an empty or partially full chamber.

Understanding the Trade-offs

Designing and operating a rotary kiln involves balancing competing priorities. Understanding these trade-offs is key to making informed decisions.

Speed vs. Thoroughness

Increasing the rotation speed can boost throughput, but it reduces the material's residence time. If the material exits before the thermal process is complete, the entire operation is inefficient, producing off-spec product and wasting fuel.

Temperature vs. Energy Cost

Higher operating temperatures can accelerate chemical reactions, but they come at a significant cost. Fuel consumption rises dramatically with temperature, as does the thermal stress on the refractory lining and steel shell, potentially leading to more frequent and costly maintenance.

Capital Cost vs. Operational Efficiency

Investing in advanced features like superior refractory materials, high-performance seals, and sophisticated process control systems increases the initial capital expenditure. However, these features directly reduce long-term operational costs by minimizing fuel consumption and maintenance downtime.

Optimizing Efficiency for Your Process

The "right" approach depends entirely on your primary objective. The definition of an efficient operation changes based on whether you prioritize throughput, quality, or cost.

- If your primary focus is maximizing throughput: Your goal is to optimize the feed rate and rotation speed to process the most material possible while still meeting minimum quality specifications.

- If your primary focus is product quality and consistency: You must prioritize precise control over the kiln's temperature profile and the material's residence time, even if it results in a lower overall throughput.

- If your primary focus is minimizing operational cost: Your investment should be in high-quality refractory linings, effective seals, and advanced heat recovery systems to minimize fuel waste over the long term.

Ultimately, rotary kiln efficiency is not a feature you buy, but a result you achieve through expert design and disciplined operation.

Summary Table:

| Key Factor | Impact on Efficiency |

|---|---|

| Thermal Management | Minimizes heat loss, ensures uniform heating |

| Material Residence Time | Controlled by rotation speed & angle for complete reaction |

| System Sealing | Prevents energy loss from air/gas leaks |

| Feed/Discharge Balance | Matches material input to kiln's thermal capacity |

Ready to optimize your thermal processing efficiency?

At KINTEK, we specialize in designing and supplying high-performance rotary kilns and lab equipment tailored to your specific needs. Whether your priority is maximizing throughput, ensuring product quality, or reducing operational costs, our expertise can help you achieve it.

We provide robust solutions with superior refractory linings, effective seals, and precise control systems to enhance your kiln's performance and longevity.

Contact us today to discuss how we can support your laboratory's thermal processing challenges and help you achieve peak efficiency. Get in touch with our experts now!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is a rotary kiln? A Guide to High-Temperature Material Processing

- What is the regeneration of carbon? Restore Your Spent Activated Carbon for Reuse

- What is a furnace for firing pottery called? Discover the Kiln: Your Key to Perfect Ceramics

- What is continuous furnace in heat treatment? Achieve High-Volume, Consistent Heat Treatment

- What is the residence time of microwave pyrolysis? Achieve Fast, Efficient Biomass Conversion

- What is a fluidized bed chemical reaction? A Guide to Superior Heat Transfer & Continuous Processing

- What is the technique of pyrolysis? A Guide to Thermal Decomposition Without Oxygen

- What is the historical origin and evolution of the rotary kiln? From 1885 Patent to Modern Industrial Giant