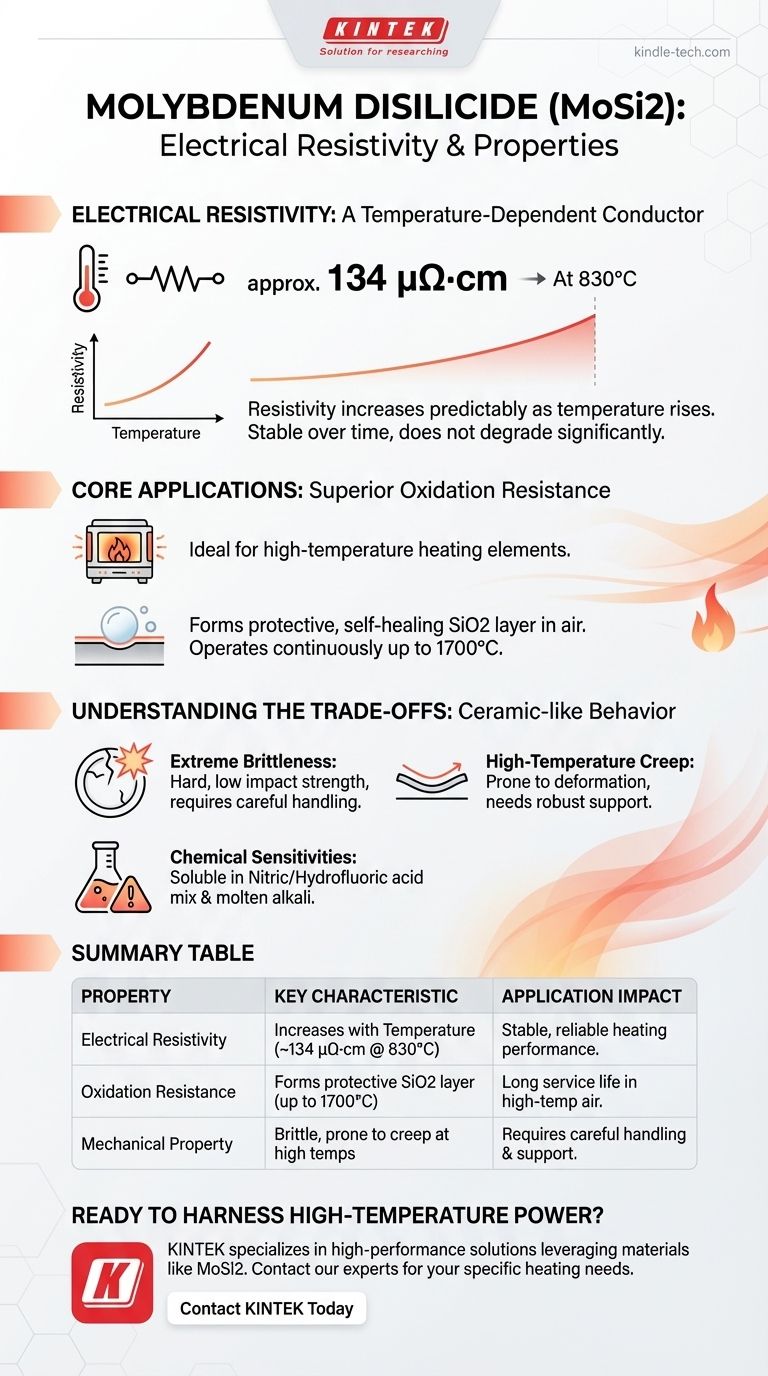

At a temperature of 830°C, the electrical resistivity of molybdenum disilicide (MoSi2) in thin film form is approximately 134 µΩ·cm. However, this single value is only part of the story. The most critical characteristic of this material is that its resistivity increases predictably as its temperature rises, a property that defines its primary applications.

The practical value of molybdenum disilicide is not found in a static resistivity number, but in its dynamic relationship with temperature. This electrical behavior, combined with its outstanding oxidation resistance, makes it a premier material for high-temperature heating elements, though this performance must be carefully balanced against its ceramic-like mechanical fragility.

The Core Electrical Properties of MoSi2

Molybdenum disilicide's electrical behavior is what makes it uniquely suited for creating extreme heat. It acts as a metallic conductor, but with properties optimized for thermal applications.

A Temperature-Dependent Conductor

The most important electrical property of MoSi2 is that its resistivity increases as temperature increases. This relationship is stable and predictable, allowing for reliable performance in heating elements.

Stability Over Time

Under normal operating conditions, the resistance of a molybdenum disilicide heating element is highly stable. It does not degrade or change significantly over its operational lifetime, which is a critical factor for industrial furnaces and processes requiring consistent output.

Why Resistivity Matters: MoSi2 in Application

The unique combination of electrical and chemical properties allows MoSi2 to function in environments where most metals would quickly fail.

Superior Oxidation Resistance

MoSi2 has exceptional resistance to oxidation at high temperatures. When heated in air, it forms a protective, self-healing layer of silicon dioxide (SiO2) on its surface. This glassy layer prevents further oxidation of the material beneath, allowing for continuous use at temperatures up to 1700°C.

High-Temperature Operation

With a melting point of 2030°C, MoSi2 is designed for extreme heat. The formation of its protective layer ensures it can operate for thousands of hours without deep oxidation, making it a workhorse for industrial and laboratory furnaces.

Understanding the Trade-offs

While its thermal and electrical performance is excellent, MoSi2 presents significant mechanical challenges. Its properties are much closer to those of a ceramic than a typical metal.

Extreme Brittleness

The material is hard but very brittle, with low impact strength. This makes MoSi2 components susceptible to fracture from mechanical shock during shipping, installation, or operation if not handled and installed with extreme care.

High-Temperature Creep

At elevated temperatures, molybdenum disilicide is prone to deformation and creep under its own weight or external loads. This means heating elements must be properly supported in their design to prevent sagging and premature failure.

Chemical Sensitivities

While it resists most inorganic acids, MoSi2 is soluble in a mixture of nitric and hydrofluoric acid as well as molten alkali. Its suitability must be confirmed in environments where these chemicals may be present.

Making the Right Choice for Your Application

Your final decision depends on balancing the material's unparalleled heating capability with its significant mechanical limitations.

- If your primary focus is reliable, high-temperature electric heating: MoSi2 is an exceptional choice due to its stable, temperature-dependent resistivity and world-class oxidation resistance.

- If your application involves mechanical stress or impact risk: You must design robust support structures to mitigate MoSi2's inherent brittleness and its tendency to creep at high temperatures.

- If you are operating in a chemically aggressive environment: Ensure your process is free from molten alkali or specific acid mixtures that are known to attack the material.

Understanding these interconnected properties is the key to successfully leveraging molybdenum disilicide in demanding high-temperature environments.

Summary Table:

| Property | Key Characteristic | Application Impact |

|---|---|---|

| Electrical Resistivity | Increases predictably with temperature (~134 µΩ·cm at 830°C) | Enables stable, reliable heating element performance |

| Oxidation Resistance | Forms protective SiO2 layer; usable up to 1700°C | Long service life in high-temperature air environments |

| Mechanical Property | Brittle, prone to creep at high temperatures | Requires careful handling and robust support design |

Ready to harness the power of molybdenum disilicide for your high-temperature processes?

KINTEK specializes in providing high-performance lab equipment and consumables, including solutions that leverage materials like MoSi2 for superior heating. Our expertise ensures you get the right equipment for reliable, high-temperature applications.

Contact our experts today to discuss how we can support your laboratory's specific heating needs!

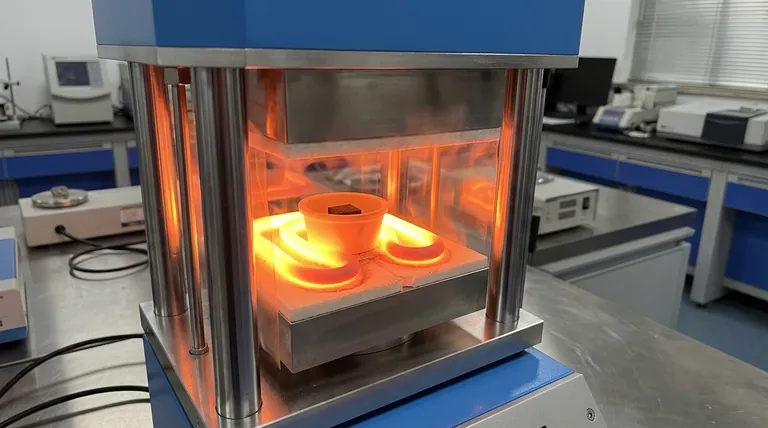

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What determines the size of a heating element? Key Factors for Optimal Performance & Lifespan

- Why does the temperature of the heating element increase? To Drive Efficient Heat Transfer

- Does molybdenum conduct heat? Unlocking Its Role in High-Temperature Applications

- What are the disadvantages of tungsten? Navigating its brittleness and high fabrication costs

- What are the advantages of using tungsten? Achieve Unmatched Performance in Extreme Environments

- Where are heating elements located within a hot zone? Expert Guide on Placement for Optimal Uniformity

- Is tungsten a good heating element? Unlock Extreme Temperatures in Vacuum Environments

- How do you know if the heating element has gone? Diagnose Common Heating Issues Quickly