At its core, a muffle furnace operates by converting electrical energy into thermal energy through a process known as resistance heating. An electric current is passed through specialized, high-resistance heating coils embedded within the furnace walls. These elements glow hot and heat the internal chamber indirectly, ensuring the sample is heated in a clean, controlled, and uniform environment without any contact with the heating source itself.

The defining mechanism of a muffle furnace is its use of an isolated chamber (the "muffle"). Electrical resistance elements heat the walls of this chamber, which then transfer heat to the sample primarily through thermal radiation, ensuring uniform heating without contamination.

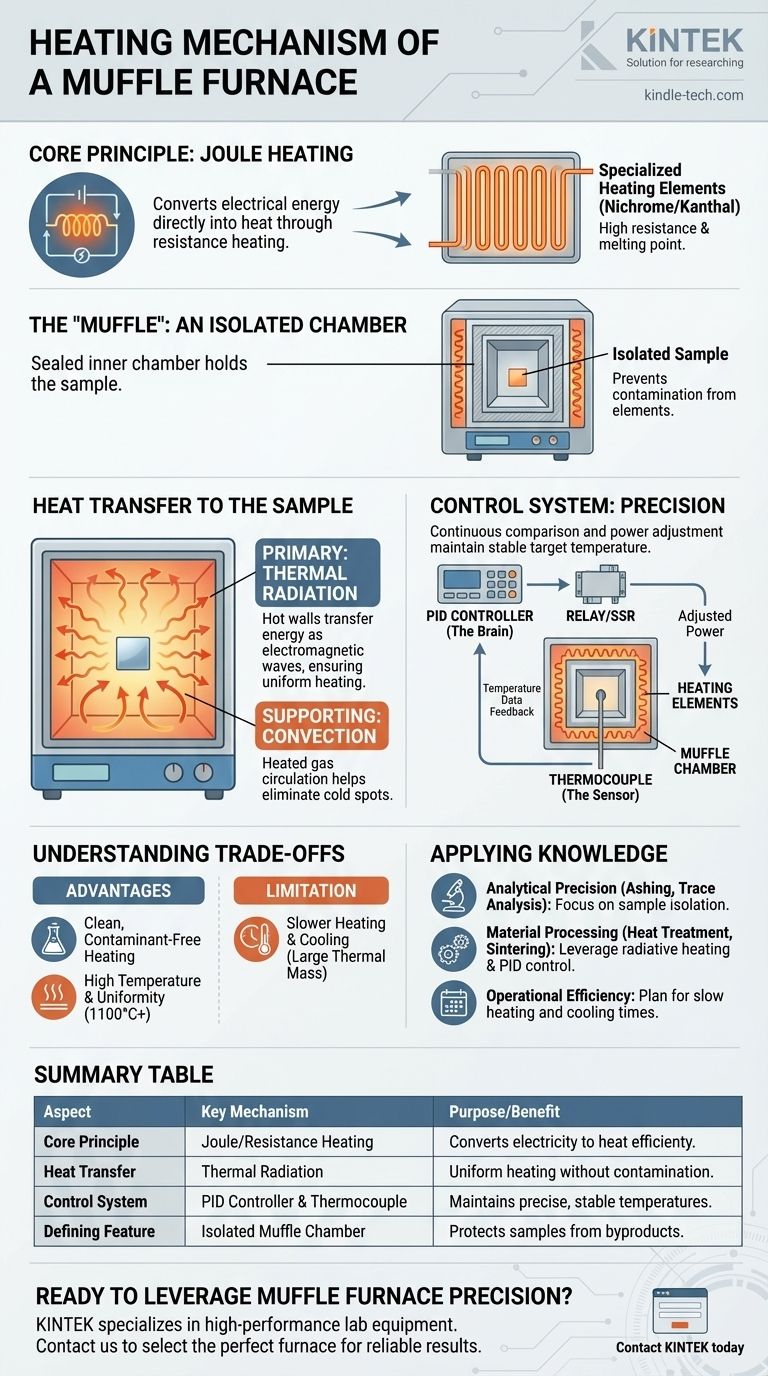

The Core Principle: From Electricity to Heat

A muffle furnace's operation is a direct application of fundamental physics. It is designed to create a stable, high-temperature environment by precisely controlling the conversion of electrical energy into heat.

Joule Heating: The Engine of the Furnace

The primary principle is Joule heating, also known as resistance heating. When an electric current flows through a material that resists its passage, electrical energy is converted directly into heat.

Think of the filament in a classic toaster. As electricity struggles to pass through the thin wires, they glow red-hot. A muffle furnace uses this exact same effect, but on a much more powerful and controlled scale.

The Role of Heating Elements

The "wires" in a muffle furnace are specialized heating elements, typically made from alloys like Nichrome or Kanthal. These materials are chosen for two critical properties:

- High electrical resistance to generate heat efficiently.

- A very high melting point and resistance to oxidation, allowing them to operate at extreme temperatures for long periods.

These elements are strategically placed within the furnace's insulation, usually surrounding the central chamber.

How Heat Reaches the Sample

Simply generating heat is not enough; the furnace must deliver it to the sample uniformly and cleanly. This is where the "muffle" design becomes critical.

The "Muffle": An Isolated Chamber

The term "muffle" refers to the sealed, inner chamber that holds the sample. This chamber is separated from the actual heating elements.

This design is crucial because it isolates the sample from any potential contaminants. In modern electric furnaces, it prevents any particles from the degrading elements from reaching the sample. In older, fuel-fired designs, it separated the sample from the byproducts of combustion.

Radiation: The Primary Heat Transfer

The heating elements heat the interior walls of the muffle chamber to a very high temperature. These hot walls then transfer thermal energy into the chamber's open space primarily through thermal radiation.

This energy travels as electromagnetic waves and is absorbed by the sample, heating it from all sides simultaneously. This is the key to the exceptionally uniform temperature environment inside a muffle furnace.

Convection: A Supporting Role

As the internal chamber heats up, the air or atmosphere inside also becomes hot. This heated gas circulates via natural convection, further helping to distribute heat and stabilize the temperature throughout the chamber. While radiation is the dominant force, convection helps eliminate any potential cold spots.

The Control System: Achieving Precision

A muffle furnace is not just a hot box; it is a precision instrument. This precision is achieved through a closed-loop control system.

The Thermocouple: The Sensor

A thermocouple is a robust temperature sensor placed inside the chamber. It constantly measures the actual internal temperature and sends this information back to the controller.

The PID Controller: The Brain

The furnace is governed by a PID (Proportional-Integral-Derivative) controller. This digital controller continuously compares the temperature measured by the thermocouple to the target temperature you have set.

Based on any difference, it intelligently adjusts the amount of power sent to the heating elements via a relay or SSR (Solid State Relay). This constant feedback and adjustment allow the furnace to maintain a highly stable temperature with minimal fluctuation.

Understanding the Trade-offs

While powerful, the design of a muffle furnace comes with specific characteristics that are important to understand for practical use.

Advantage: Clean, Contaminant-Free Heating

The physical separation between the heating elements and the sample is the furnace's greatest strength. It is essential for applications like ashing chemical samples or testing material purity, where any external contamination would invalidate the results.

Advantage: High Temperature and Uniformity

The insulated, radiative design allows the furnace to achieve very high temperatures (often over 1100°C) and maintain excellent temperature uniformity across the entire sample, which is critical for consistent material processing.

Limitation: Slower Heating and Cooling

The furnace's walls and insulation represent a large thermal mass that must be heated. Consequently, muffle furnaces can take a significant amount of time to reach their target temperature and, more importantly, a very long time to cool down safely.

Applying This Knowledge in Practice

Understanding the heating mechanism helps you use the furnace more effectively and troubleshoot potential issues.

- If your primary focus is analytical precision (e.g., ashing, trace analysis): The key is the "muffle" design, which isolates your sample from heating element contamination and ensures the integrity of your results.

- If your primary focus is material processing (e.g., heat treatment, sintering): The combination of radiative heating and PID control provides the highly uniform and stable high-temperature environment crucial for predictable material transformations.

- If your primary focus is operational efficiency: Recognize that the furnace's high thermal mass means it heats and cools slowly, so you must plan your lab work and cooldown procedures accordingly.

By understanding that a muffle furnace is a precision instrument based on controlled electrical resistance and radiative heat transfer, you can better leverage its power for reliable and repeatable results.

Summary Table:

| Aspect | Key Mechanism | Purpose/Benefit |

|---|---|---|

| Core Principle | Joule/Resistance Heating | Converts electricity into heat efficiently |

| Heat Transfer | Primarily Thermal Radiation | Ensures uniform heating without contamination |

| Control System | PID Controller & Thermocouple | Maintains precise, stable target temperatures |

| Defining Feature | Isolated Muffle Chamber | Protects samples from heating element byproducts |

Ready to leverage the precision of a muffle furnace in your lab? KINTEK specializes in high-performance lab equipment, including durable muffle furnaces designed for contaminant-free ashing, heat treatment, and material processing. Our experts can help you select the perfect furnace to ensure reliable, repeatable results for your specific application. Contact KINTEL today to discuss your laboratory needs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How do you handle a muffle furnace? A Step-by-Step Guide for Safe & Accurate Operation

- Does heat capacity affect melting point? Unraveling the Key Differences in Thermal Properties

- Is a muffle furnace an oven? A Guide to High-Temperature vs. Low-Temperature Heating

- What temperature does steel liquify? Understanding the Melting Range for Your Applications

- How do you check the temperature of a muffle furnace? A Guide to Precise Monitoring