While there is no single maximum pressure for all hydraulic presses, a specific model might have a maximum allowable system pressure of around 400 kg/cm² (kilograms per square centimeter). This internal system pressure is a design limit. The true power of a hydraulic press, however, is not the pressure itself but how that pressure is multiplied into a much larger output force, often measured in tons.

The most critical concept to understand is that the "highest pressure" is a system rating, but the immense force a press generates is the result of that pressure being applied over a large surface area, a principle known as Pascal's Law. This distinction between internal pressure and output force is key.

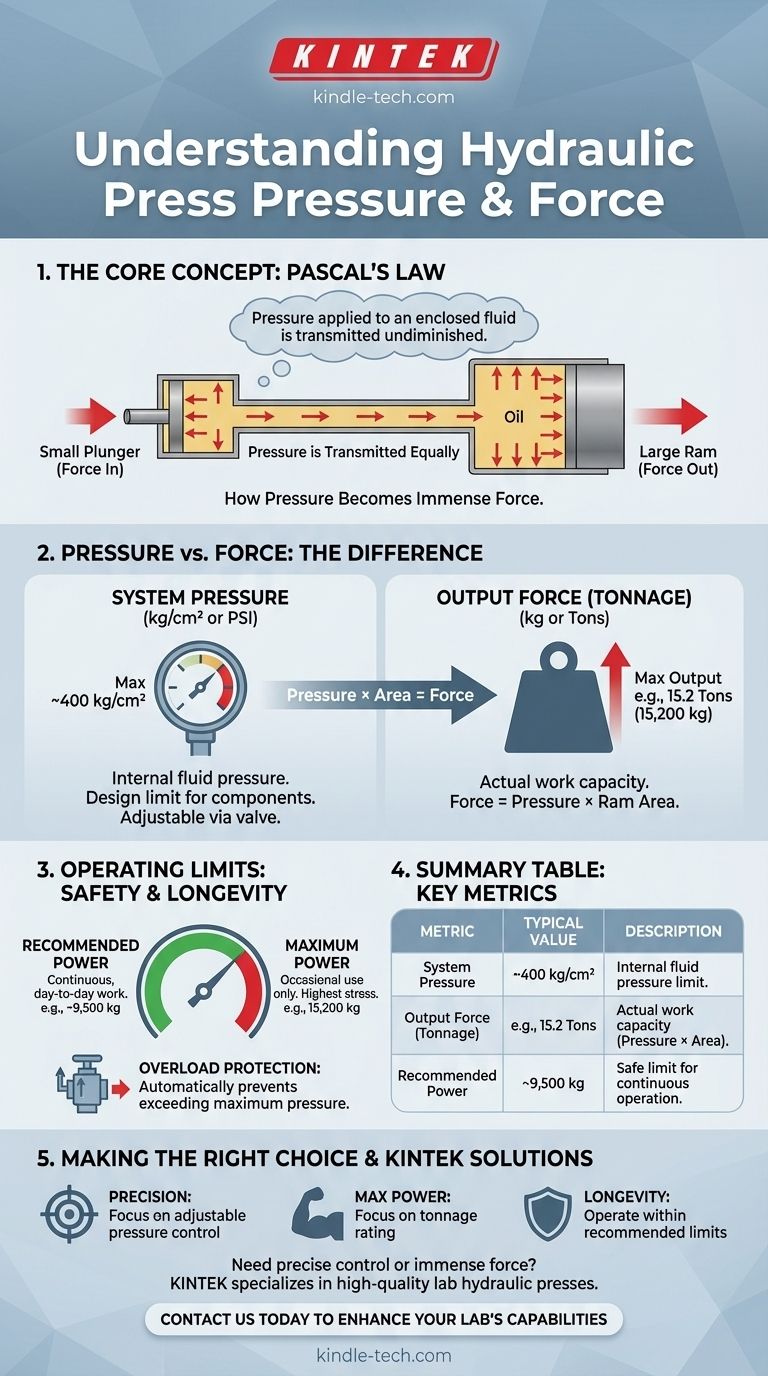

The Principle: How Pressure Becomes Force

A hydraulic press operates on a simple yet powerful principle that allows it to multiply force significantly.

The Core Concept: Pascal's Law

Pascal's Law states that when pressure is applied to an enclosed fluid, that pressure is transmitted equally and undiminished to every part of the fluid and the walls of the container.

In a press, this fluid is typically oil. This means the pressure created by the pump is felt uniformly throughout the entire hydraulic system.

From Pressure to Force: The Two-Cylinder System

A press consists of two main cylinders of different sizes connected by this fluid: a small plunger and a large ram.

When a small force is applied to the small plunger, it creates pressure in the fluid (Pressure = Force / Area). Because this pressure is transmitted equally, the same pressure now pushes up on the much larger ram.

Since the ram has a much larger surface area, the resulting output force is magnified enormously. This is why a small effort on a hand pump can generate tons of force at the workpiece.

Decoding the Specifications: Pressure vs. Force

It's easy to confuse the internal pressure of a press with its output force or tonnage. They are related but distinct metrics.

System Pressure (kg/cm² or PSI)

This is the amount of force exerted on every square centimeter (or square inch) of the hydraulic fluid. In the reference example, the maximum allowed pressure is 400 kg/cm².

This value is determined by the strength of the pump, hoses, seals, and cylinder walls. An adjustable valve allows the operator to control this pressure for different tasks.

Output Force or Tonnage (kg or Tons)

This is the actual work capacity of the press—the total force the ram can exert on an object. This is the number most users care about (e.g., a "20-ton press").

This force is the product of the system pressure and the area of the ram's piston. The 15,200 kg (15.2 metric tons) rating in the specifications is the maximum output force, which is achieved when the system reaches its maximum pressure of 400 kg/cm².

Understanding the Operational Limits

Knowing the difference between maximum and recommended ratings is crucial for both safety and the longevity of the machine.

Maximum vs. Recommended Power

The reference lists a maximum allowed power of 15,200 kg and a maximum recommended power of 9,500 kg.

Operating at the absolute maximum limit should be done sparingly. It places the highest stress on all components and can lead to premature wear. The "recommended" power is the limit for continuous, day-to-day work to ensure a long service life.

Built-in Overload Protection

Most hydraulic presses include a pressure relief valve. This is a critical safety feature that automatically prevents the system from exceeding its maximum designed pressure, protecting the machine from damage and the operator from potential failure.

Making the Right Choice for Your Goal

Your focus should be on the metric that best aligns with your application's needs.

- If your primary focus is repeatable precision: Concentrate on finding a press with a high-quality, adjustable pressure control valve. The ability to set and reproduce a specific system pressure is more important than the absolute maximum force.

- If your primary focus is maximum forming or crushing power: Look at the tonnage rating (e.g., 15 tons, 50 tons, 100 tons). This number is the direct measure of the press's work capacity.

- If your primary focus is longevity and safety: Always operate within the manufacturer's "recommended" pressure and force range, reserving the "maximum" capacity for only occasional needs.

By understanding the relationship between internal pressure and output force, you can leverage the full power of a hydraulic press with both precision and confidence.

Summary Table:

| Metric | Typical Value | Description |

|---|---|---|

| System Pressure | ~400 kg/cm² | Internal fluid pressure, a design limit for the pump and hoses. |

| Output Force (Tonnage) | e.g., 15.2 Tons | The actual work capacity, calculated as Pressure × Ram Area. |

| Recommended Power | ~9,500 kg | The safe limit for continuous, day-to-day operation. |

Need precise control or immense force for your laboratory tasks? KINTEK specializes in high-quality lab equipment, including hydraulic presses designed for reliability, safety, and performance. Our experts can help you select the perfect press to meet your specific application needs, ensuring you get the right balance of precision and power. Contact us today to enhance your lab's capabilities with KINTEK!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

People Also Ask

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy