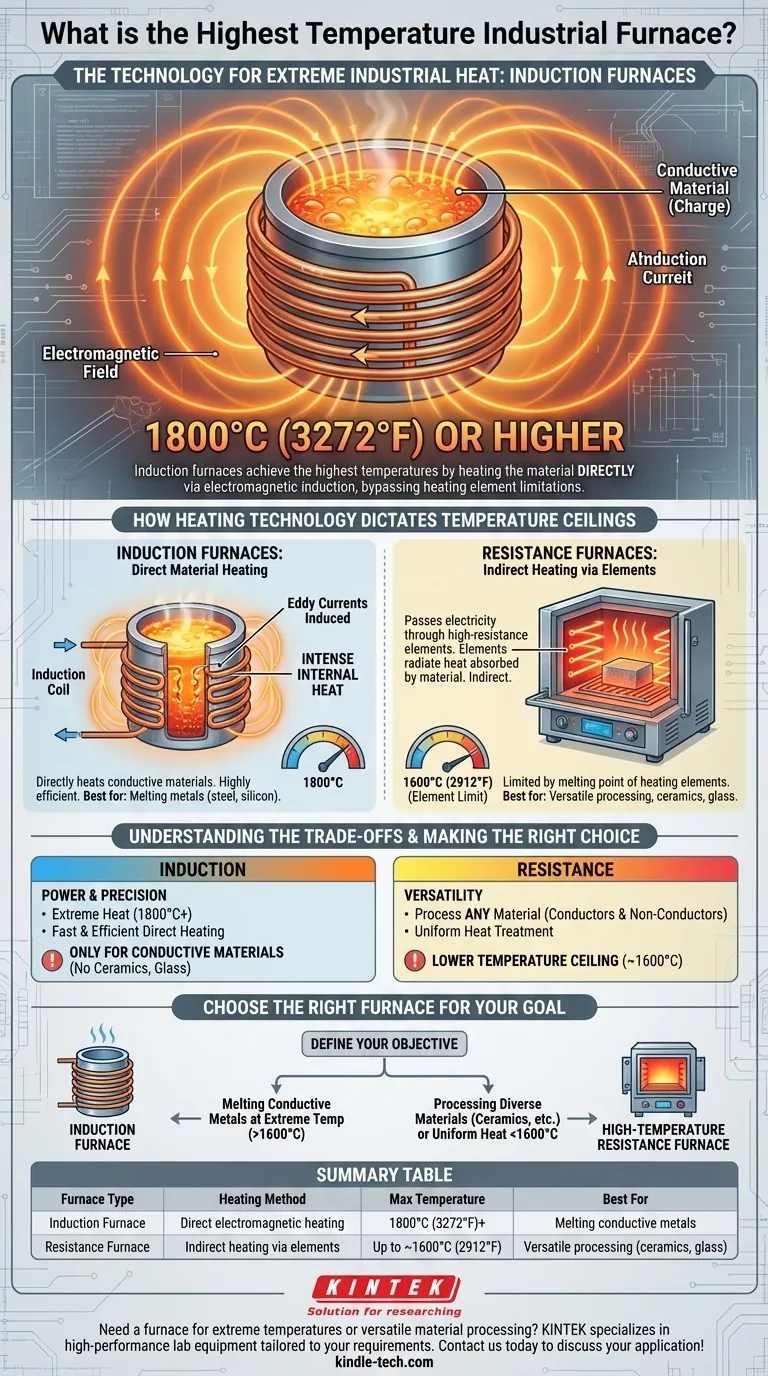

For the highest industrial temperatures, the technology that stands out is the induction furnace. Based on the inductive coupling between the coil and the charge materials, these specialized furnaces can reach temperatures of 1800°C (3272°F) or higher, exceeding the capabilities of many other furnace types.

The maximum temperature of an industrial furnace is not a single number but is defined by its underlying heating technology. Induction furnaces achieve the highest temperatures by heating the material directly, bypassing the physical limitations of traditional resistance heating elements.

How Heating Technology Dictates Temperature Ceilings

The core difference between the highest-temperature furnaces and more common variants lies in how they generate heat. This distinction directly impacts their operational limits.

Induction Furnaces: Direct Material Heating

An induction furnace does not use conventional heating elements. Instead, it uses a powerful alternating current passed through a copper coil to create a strong electromagnetic field.

This field induces eddy currents directly within the conductive material (the "charge") placed inside the furnace. This process generates intense heat from within the material itself, allowing it to reach extreme temperatures like 1800°C.

Resistance Furnaces: Indirect Heating via Elements

Most other industrial furnaces, such as a bottom-loading furnace, are resistance furnaces. They operate by passing electricity through high-resistance heating elements.

These elements glow hot and radiate heat, which is then absorbed by the material inside the furnace. This method is effective and versatile but is limited by the melting point of the heating elements themselves, often capping the maximum temperature around 1600°C (2912°F).

Understanding the Trade-offs

Choosing a furnace is not just about finding the highest possible temperature. The right choice depends on the material being processed and the specific application goal. Each technology comes with a distinct set of advantages and limitations.

The Power and Precision of Induction

Induction furnaces are the clear choice for processes requiring extreme heat, such as melting steel, silicon, or other conductive metals. The direct heating method is incredibly fast and efficient.

However, their primary limitation is that they can only heat electrically conductive materials. They are less suitable for processing ceramics, glass, or other insulators.

The Versatility of High-Temperature Resistance

Resistance furnaces offer far greater versatility. Because they heat materials indirectly through radiation and convection, they can process nearly any material, including non-conductors like ceramics.

Their main trade-off is the temperature ceiling. While advanced models can reach high temperatures, they cannot match the extreme capabilities of induction technology due to the physical limits of their heating elements.

Making the Right Choice for Your Goal

To select the appropriate technology, you must first define your primary objective.

- If your primary focus is melting metals or other conductive materials at extreme temperatures (>1600°C): An induction furnace is the superior and often only choice for the application.

- If your primary focus is processing diverse materials, including non-conductors like ceramics, or achieving uniform heat treatment below 1600°C: A high-temperature resistance furnace provides the necessary versatility and control.

Ultimately, understanding the fundamental heating mechanism is the key to selecting the right tool for your high-temperature application.

Summary Table:

| Furnace Type | Heating Method | Max Temperature | Best For |

|---|---|---|---|

| Induction Furnace | Direct heating via electromagnetic field | 1800°C (3272°F) or higher | Melting conductive metals (steel, silicon) |

| Resistance Furnace | Indirect heating via elements | Up to ~1600°C (2912°F) | Versatile processing of ceramics, glass, and other materials |

Need a furnace for extreme temperatures or versatile material processing? KINTEK specializes in high-performance lab equipment, including industrial furnaces tailored to your specific material and temperature requirements. Whether you're melting metals or processing ceramics, our experts will help you select the right technology for maximum efficiency and results. Contact us today to discuss your high-temperature application!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?