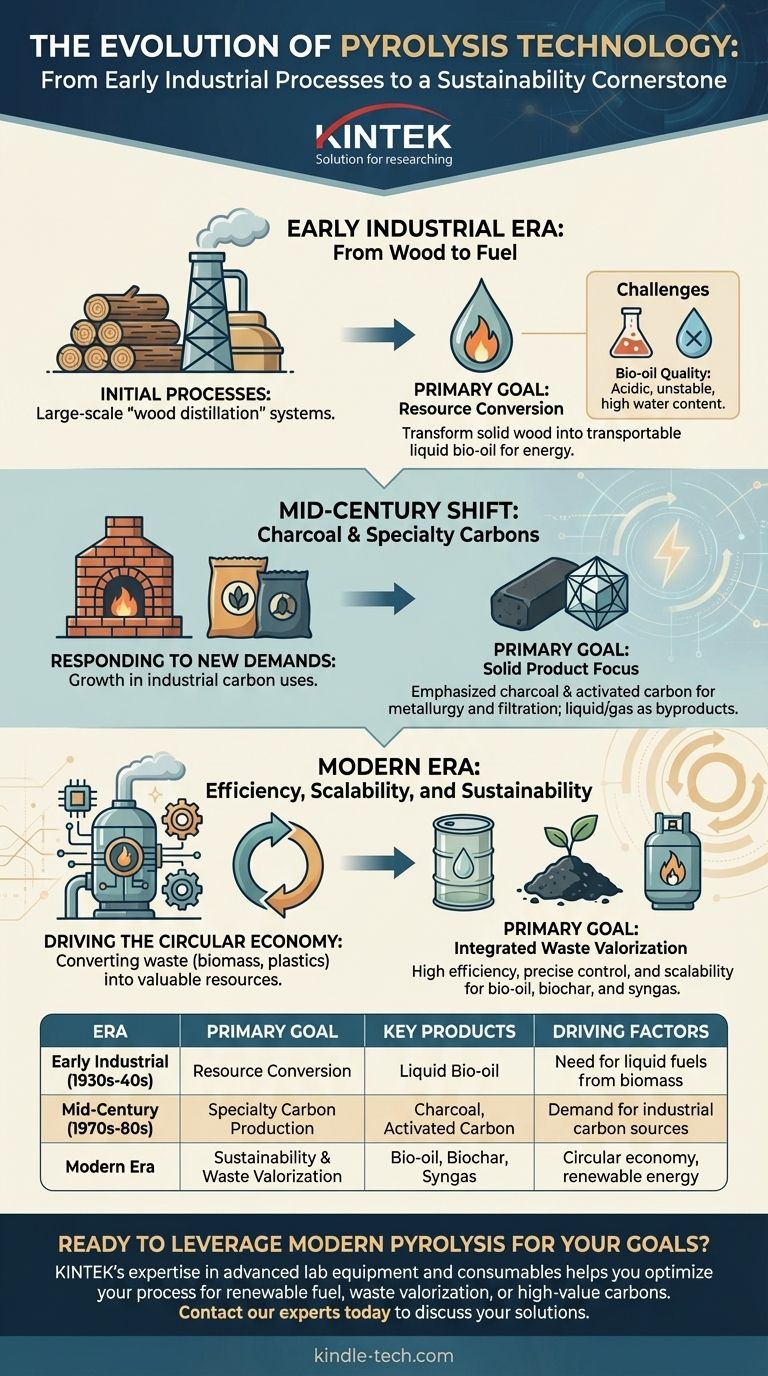

The history of pyrolysis technology is one of continuous adaptation, evolving from early industrial processes for chemical production into a sophisticated tool for sustainability and waste management. Its development accelerated in the 1930s and 40s with methods to convert wood into liquid fuel, shifted focus in the 1970s and 80s toward producing charcoal and activated carbon, and has now entered a modern era defined by high efficiency and a wide range of applications.

The core takeaway from the history of pyrolysis is its evolution from a simple thermal decomposition method into a refined technology driven by changing needs. Initially used for bulk resource conversion, it is now a cornerstone technology for the circular economy, aimed at creating high-value products from waste streams.

The Early Industrial Era: From Wood to Fuel

The first significant industrial applications of pyrolysis emerged in the early-to-mid 20th century, driven by the need to create liquid fuels and chemical feedstocks from abundant biomass like wood.

Initial Industrial Processes

Around the 1930s and 1940s, large-scale systems were developed specifically to convert wood into liquid products. This process, often called "wood distillation," was a foundational step in chemical engineering.

The Primary Goal: Resource Conversion

The motivation during this period was straightforward: transform a solid, low-density resource (wood) into a more energy-dense and transportable liquid fuel. The primary output of value was the liquid bio-oil.

A Mid-Century Shift: The Rise of Charcoal and Specialty Carbons

By the 1970s and 1980s, global economic and industrial priorities had changed. This prompted a significant shift in how pyrolysis technology was applied, moving the focus from the liquid output to the solid output.

Responding to New Demands

The emphasis moved toward producing charcoal and activated carbon. These materials had growing applications in metallurgy, water filtration, and other industrial processes that required high-purity carbon sources.

A Focus on the Solid Product

In these applications, the solid biochar was the main product, while the liquid and gas fractions were often seen as secondary byproducts, sometimes used simply to provide energy for the process itself. This marked a fundamental change in the economic model of pyrolysis operations.

The Modern Era: Efficiency, Scalability, and Sustainability

Recent advancements in pyrolysis have been transformational, driven by the urgent global need for renewable energy and sustainable waste management. The technology is now more precise, efficient, and scalable than ever before.

Driving the Circular Economy

Today, pyrolysis is a key technology for converting waste biomass, plastics, and other materials into valuable resources. This aligns perfectly with the principles of a circular economy, where waste is eliminated and resources are continually reused.

Key Technological Leaps

Modern pyrolysis systems feature vastly improved efficiency through better heat transfer and process control. This allows for precise tuning of the process to maximize the yield of desired products—whether it's bio-oil, biochar, or syngas.

These improvements have also enabled incredible scalability. Pyrolysis is now used in everything from small, decentralized heating systems to massive industrial plants that process thousands of tons of feedstock per day.

Understanding the Trade-offs and Historical Hurdles

The evolution of pyrolysis was not seamless. Its history is shaped by efforts to overcome persistent technical challenges that limited its widespread adoption for decades.

The Challenge of Bio-oil Quality

Historically, the bio-oil produced through pyrolysis was often acidic, unstable, and contained high levels of water and oxygen. This made it difficult to use as a drop-in fuel without extensive and costly upgrading, which was a major barrier in its early history.

The Efficiency and Yield Problem

Early reactors were often inefficient, leading to lower-than-desired yields of the target product. Much of the recent innovation has focused on reactor design and catalysts to control the chemical reactions and maximize the output of valuable products while minimizing waste.

Making the Right Choice for Your Goal

The historical context of pyrolysis helps clarify its modern applications. Your approach depends entirely on your end goal.

- If your primary focus is creating soil amendments or specialty carbons: You are following the path established in the 1970s, but with modern technology that gives you precise control over the quality and properties of the final biochar.

- If your primary focus is producing renewable fuels: You are building on the original 1930s goal, but leveraging recent advancements in catalytic pyrolysis and oil upgrading to create stable, high-energy-density liquid fuels.

- If your primary focus is waste valorization: You are embracing the modern, integrated approach, where all products (oil, char, and gas) are seen as valuable outputs in a circular economic model.

Understanding this technological journey is the key to effectively applying pyrolysis as a powerful solution for today's energy and environmental challenges.

Summary Table:

| Era | Primary Goal | Key Products | Driving Factors |

|---|---|---|---|

| Early Industrial (1930s-40s) | Resource Conversion | Liquid Bio-oil | Need for liquid fuels from biomass |

| Mid-Century (1970s-80s) | Specialty Carbon Production | Charcoal, Activated Carbon | Demand for industrial carbon sources |

| Modern Era | Sustainability & Waste Valorization | Bio-oil, Biochar, Syngas | Circular economy, renewable energy, advanced process control |

Ready to leverage modern pyrolysis technology for your sustainability goals?

The history of pyrolysis shows a technology refined for efficiency and specific outcomes. Whether your goal is renewable fuel production, waste valorization, or creating high-value carbon products, KINTEK's expertise in advanced lab equipment and consumables can help you optimize your process.

Contact our experts today to discuss how our solutions can support your research and development in pyrolysis and the circular economy.

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Is pyrolysis good for the Environment? Unlocking Its Potential for Waste & Carbon Reduction

- What does the pyrolysis of wood release? Unlocking Biochar, Bio-Oil, and Syngas

- What are the emissions from pyrolysis of wood? Understanding VOC and Particulate Matter Risks

- What are the benefits of pyrolysis plastic? Transform Waste into Fuel & New Materials

- What is the purpose of pyrolysis plant? Convert Waste into Valuable Resources

- Which catalyst used in biomass pyrolysis for production of bio-oil? Select the Right Catalyst for Your Bio-Oil

- What are the components of a pyrolysis machine? A Complete Breakdown of the Core System

- What are the benefits of biomass pyrolysis? Transform Waste into Sustainable Energy & Economic Assets