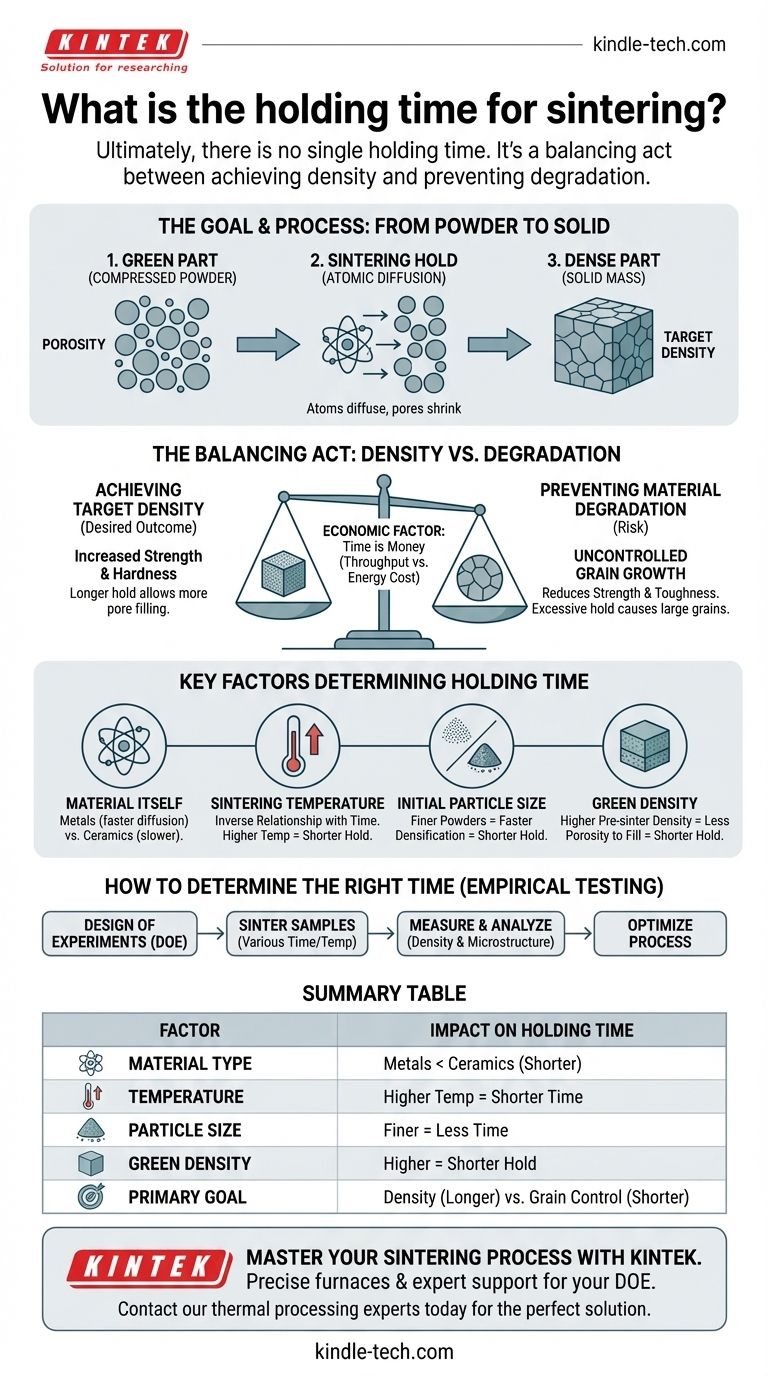

Ultimately, there is no single holding time for sintering. The correct duration is not a fixed number but a variable that depends entirely on your material, your equipment, and your desired outcome. While typical holding times range from 30 minutes to several hours, this value is the result of a careful balancing act between achieving density and preventing material degradation.

The core challenge is not finding a magic number for holding time, but understanding it as a tool. Your goal is to provide just enough time for atomic diffusion to eliminate porosity and create a dense part, but not so much time that you cause excessive grain growth, which can weaken the final component.

What is the Goal of the Sintering Hold?

The holding period, also known as the "soak time," is the critical phase where the actual consolidation of the material occurs. It happens after the furnace has ramped up to the target sintering temperature.

From Powder to Solid

Sintering is a thermal process that bonds powder particles together into a solid mass at a temperature below the material's melting point. The hold time is the period you allow this bonding to take place.

Initially, you have a "green" part made of compressed powder with significant empty space (porosity) between particles. The goal of the hold is to reduce or eliminate this porosity.

The Role of Atomic Diffusion

During the hold, atoms move or diffuse from the points of contact between particles to fill the voids. This process is what causes the part to shrink and become denser.

Time is the variable that allows this diffusion to progress. Insufficient time means diffusion is incomplete, leaving behind pores and resulting in a weak, under-dense part.

Key Factors That Determine Holding Time

Holding time is intrinsically linked to several other process variables. You cannot define one without considering the others.

The Material Itself

Different materials have vastly different diffusion rates. Metals, with their metallic bonds, generally allow for faster diffusion and can often be sintered in shorter times than ceramics, which have strong covalent or ionic bonds that make atomic movement more difficult.

Sintering Temperature

Temperature is the most powerful lever you can pull. Higher temperatures dramatically accelerate the rate of atomic diffusion.

Therefore, holding time and temperature have an inverse relationship. You can often achieve the same level of densification by using a shorter hold at a higher temperature, or a longer hold at a lower temperature.

Initial Particle Size and Shape

Finer powders, with their higher surface area-to-volume ratio, have a greater thermodynamic driving force for sintering. They will densify faster than coarser powders, allowing for a shorter holding time.

"Green" Density and Preparation

The density of your part before sintering is critical. A part that has been compacted to a higher green density already has less pore volume to eliminate. This requires less material transport and can significantly shorten the necessary hold time.

Understanding the Trade-offs: Density vs. Degradation

Optimizing holding time is a classic engineering trade-off. You are balancing a desired outcome against potential negative consequences.

The Primary Goal: Achieving Target Density

The main reason for the hold is to achieve the target density, which is directly related to the mechanical properties of the final part, such as strength and hardness. The longer the hold, the more time for pores to be filled and density to increase.

The Primary Risk: Uncontrolled Grain Growth

While atoms are filling pores, they are also rearranging themselves into larger crystal structures, a process called grain growth. If the hold is too long, these grains can become excessively large.

Large grains can be detrimental, often reducing the material's strength, toughness, and fracture resistance. The final stage of sintering is a race between eliminating the last few pores and preventing runaway grain growth.

The Economic Factor: Throughput and Energy Cost

From an industrial perspective, time is money. Longer holding times mean higher energy consumption per part and lower furnace throughput. Finding the shortest possible time that still meets the quality specification is a major economic driver.

How to Determine the Right Holding Time

There is no substitute for empirical testing. The ideal method is to conduct a design of experiments (DOE) where you sinter samples at various time and temperature combinations, then measure their density and analyze their microstructure (grain size).

- If your primary focus is achieving maximum theoretical density: You may need to explore longer holding times at slightly lower temperatures to allow for full densification while carefully limiting grain growth.

- If your primary focus is high-volume manufacturing: You will likely prioritize shorter cycle times by using the highest temperature possible that doesn't cause thermal shock or unacceptable grain growth.

- If your primary focus is process development for a new material: Start with a sintering study. Create a matrix of tests with varying hold times (e.g., 30, 60, 120, 240 minutes) at a fixed temperature to understand how density and grain size evolve over time.

Mastering holding time is about controlling a dynamic process, not just setting a timer.

Summary Table:

| Factor | Impact on Holding Time |

|---|---|

| Material Type | Metals typically require shorter times than ceramics. |

| Sintering Temperature | Higher temperature allows for shorter hold time. |

| Particle Size | Finer powders generally require less time. |

| Green Density | Higher pre-sinter density can shorten the hold. |

| Primary Goal | Longer holds increase density but risk grain growth. |

Master Your Sintering Process with KINTEK

Determining the precise holding time is critical for achieving the mechanical properties and density you need in your final components. At KINTEK, we specialize in providing the high-quality lab furnaces and expert support necessary for precise thermal processing.

Our sintering furnaces offer the precise temperature control and uniformity required to run your design of experiments (DOE) and optimize your hold time for any material, from metals to advanced ceramics.

Let us help you enhance your production efficiency and part quality.

Contact our thermal processing experts today to discuss your specific application and find the perfect furnace solution for your laboratory.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia

- What makes zirconia translucent? The Science Behind Modern Dental Aesthetics

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations