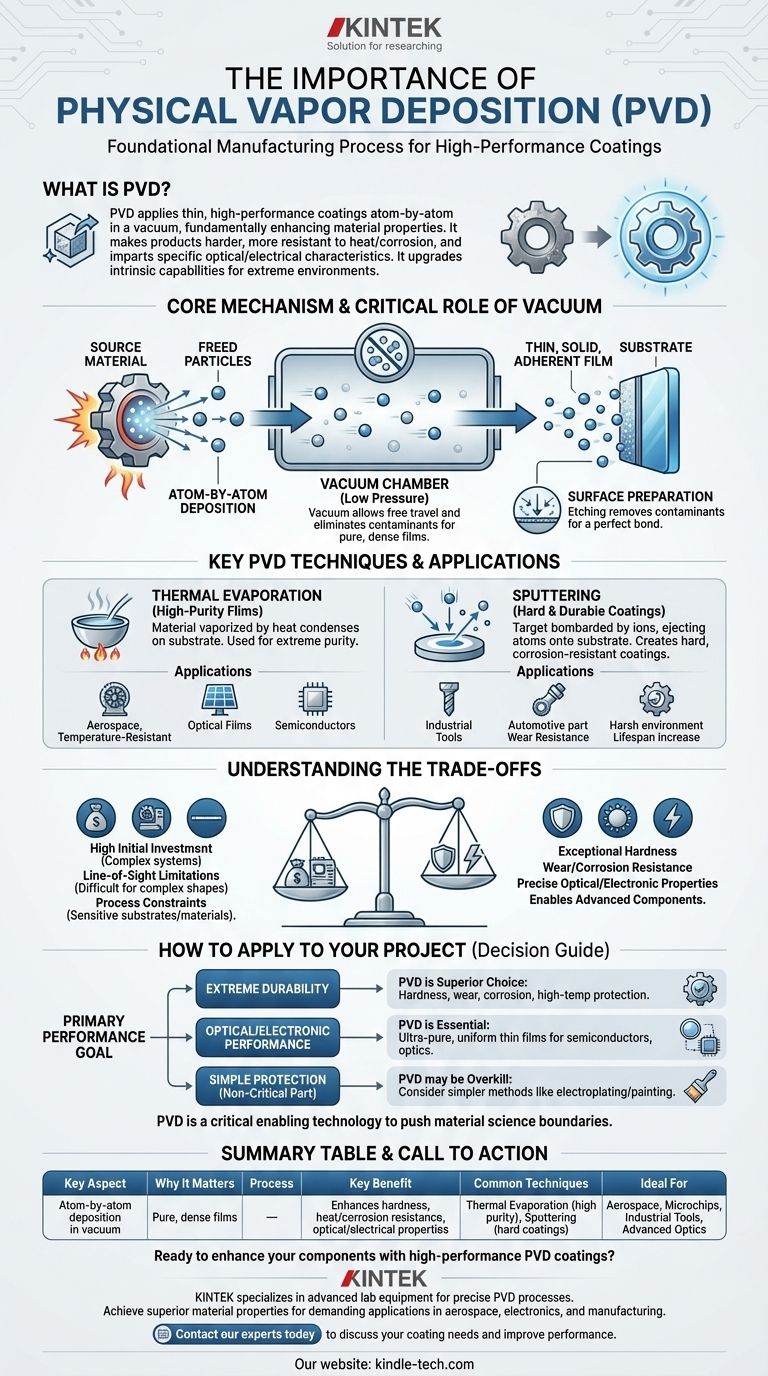

In short, physical vapor deposition (PVD) is important because it is a foundational manufacturing process for applying thin, high-performance coatings that fundamentally enhance the properties of a material. By depositing films atom-by-atom in a vacuum, PVD can make products harder, more resistant to heat and corrosion, or give them specific optical or electrical characteristics that are otherwise unattainable.

The true significance of PVD is not just in applying a coating, but in upgrading a material's intrinsic capabilities. It enables the creation of advanced components—from jet engine turbines to microchips—that can function and survive in extreme environments.

How PVD Fundamentally Alters a Material's Surface

To understand the importance of PVD, you must first understand its core mechanism. It is not like painting; it is a process of building a new surface layer molecule by molecule.

The Core Principle: Atom-by-Atom Deposition

The process begins by placing a source material (the desired coating) into an energetic environment inside a vacuum chamber. This energy, often from heat or ion bombardment, causes individual atoms or molecules to "escape" the surface of the source material.

These freed particles then travel through the vacuum and strike a target object, known as the substrate. Upon impact with the cooler substrate, the particles condense and form a thin, solid, and highly adherent film.

The Critical Role of the Vacuum

The entire process must occur in a low-pressure vacuum for two critical reasons. First, it ensures there are no other gas molecules to collide with, allowing the coating particles to travel freely and directly from the source to the substrate.

Second, the vacuum eliminates airborne contaminants. This pristine environment is essential for creating a pure, dense film and achieving a strong bond between the coating and the substrate.

Ensuring a Perfect Bond: Surface Preparation

For the coating to perform its function, it must adhere perfectly. Before deposition begins, an etching process is often used on the substrate's surface.

This pre-treatment step uses ions to scour the surface, removing microscopic oxides and contaminants. This ensures the deposited film bonds directly to the base material, maximizing adhesion and overall durability.

Key PVD Techniques and Their Applications

Different PVD methods are suited for different outcomes. The two most common are thermal evaporation and sputtering, each with distinct industrial applications.

Thermal Evaporation for High-Purity Films

Thermal evaporation involves heating a material until it vaporizes. This vapor then travels through the vacuum and condenses onto the substrate.

This technique is crucial for applications demanding high purity. Aerospace companies use it to apply dense, temperature-resistant coatings to components like turbine blades, enabling them to withstand extreme operational heat. It is also used to create precise optical films for solar panels and semiconductors.

Sputtering for Hard and Durable Coatings

Sputtering is a more forceful process. Here, a target of the coating material is bombarded with high-energy ions, which physically knock atoms off the target. These ejected atoms then deposit onto the substrate.

This method excels at creating exceptionally hard and corrosion-resistant coatings. It is the standard for protecting industrial tools, drill bits, and other components used in harsh environments, dramatically increasing their lifespan and performance.

Understanding the Trade-offs

While powerful, PVD is not a universal solution. Acknowledging its limitations is key to using it effectively.

High Initial Investment

PVD systems require vacuum chambers, high-energy sources, and precise controls. This makes the equipment complex and expensive, representing a significant capital investment compared to simpler coating methods.

Line-of-Sight Limitations

In most PVD processes, the coating material travels in a straight line from the source to the substrate. This line-of-sight nature can make it difficult to uniformly coat complex, three-dimensional shapes with hidden surfaces or deep cavities.

Process and Material Constraints

The high temperatures or ion bombardment involved in PVD can damage sensitive substrates. Furthermore, not all materials can be effectively vaporized or sputtered, limiting the available coating options for certain applications.

How to Apply This to Your Project

Your choice to use PVD should be driven entirely by your primary performance goal.

- If your primary focus is extreme durability: PVD is the superior choice for creating coatings that provide exceptional hardness, wear resistance, and protection against corrosion and high temperatures.

- If your primary focus is optical or electronic performance: PVD is essential for depositing the ultra-pure, uniform, and precise thin films required for semiconductors, solar cells, and advanced optics.

- If your primary focus is simple corrosion protection on a non-critical part: PVD may be overkill; simpler, less expensive methods like electroplating or painting might be more cost-effective.

Ultimately, physical vapor deposition is a critical enabling technology that allows engineers to push the boundaries of material science.

Summary Table:

| Key Aspect | Why It Matters |

|---|---|

| Process | Atom-by-atom deposition in a vacuum for pure, dense films. |

| Key Benefit | Enhances hardness, heat/corrosion resistance, and optical/electrical properties. |

| Common Techniques | Thermal Evaporation (high purity), Sputtering (hard coatings). |

| Ideal For | Aerospace components, microchips, industrial tools, and advanced optics. |

Ready to enhance your components with high-performance PVD coatings?

KINTEK specializes in advanced lab equipment and consumables for precise PVD processes. Our solutions help you achieve superior material properties for demanding applications in aerospace, electronics, and manufacturing.

Contact our experts today to discuss how we can support your coating needs and improve your product's performance and durability.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is the plasma CVD process? Achieve Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition