The fundamental difference between Atomic Layer Deposition (ALD) and Chemical Vapor Deposition (CVD) lies in their reaction mechanisms. ALD builds films one atomic layer at a time through sequential, self-limiting chemical reactions, offering unparalleled precision. CVD, in contrast, uses a continuous, simultaneous reaction of precursor gases, enabling much faster deposition rates.

The choice between ALD and CVD hinges on a critical trade-off: precision versus speed. ALD provides atomic-level control for complex and ultrathin films, while CVD offers higher throughput for thicker layers where absolute precision is less critical.

The Mechanics of Deposition: Sequential vs. Continuous

To understand the practical differences, we must first examine how each process works at a fundamental level. The core distinction is whether the chemical reactions happen sequentially or all at once.

How CVD Works: A Continuous Reaction

In a Chemical Vapor Deposition (CVD) process, all precursor gases are introduced into the reaction chamber simultaneously.

These gases react together on and above the heated substrate, leading to a continuous deposition of the desired thin film. This process is fast and efficient for growing relatively thick layers of material.

How ALD Works: A Separated, Self-Limiting Process

Atomic Layer Deposition (ALD) is a more controlled, cyclical variant of CVD. It breaks the overall reaction into two or more separate half-reactions.

First, one precursor gas is pulsed into the chamber, where it forms a single, self-limiting atomic layer on the substrate. Any excess gas is purged. Then, a second precursor is pulsed in to react with the first layer, completing the material deposition for that cycle before it too is purged. This cycle repeats to build the film layer by atomic layer.

Key Differentiators in Practice

The mechanical differences between these two methods lead to distinct outcomes in film quality, coverage, and speed.

Film Thickness and Control

ALD offers atomic-level precision in controlling film thickness. Because the film is built one monolayer at a time, you can achieve a specific thickness with extreme accuracy, making it ideal for the ultrathin films (10-50 nm) required in modern electronics.

CVD provides less granular control but is perfectly suitable for applications requiring thicker films where nanometer-level precision is unnecessary.

Conformality and Coverage

Conformality refers to a film's ability to coat uneven surfaces and complex 3D structures uniformly.

ALD provides near-perfect, isotropic conformality. Its self-limiting nature ensures that every surface, including deep trenches and high-aspect-ratio structures, is coated evenly. This is a significant advantage over "line-of-sight" methods like physical vapor deposition (PVD).

While CVD offers good conformality, it can struggle to maintain uniform thickness inside very complex or deep structures compared to ALD.

Deposition Rate

The most significant advantage of CVD is its high deposition rate. Since the reaction is continuous, films can be grown much more quickly.

ALD is an inherently slow process. The repeated cycles of pulsing and purging limit its throughput, making it less practical for applications demanding thick films or high-volume production.

Understanding the Trade-offs

Choosing between ALD and CVD requires weighing their respective strengths and weaknesses against your specific goals.

The Precision of ALD

The primary advantage of ALD is its unparalleled control over film thickness, density, and uniformity. This precision is non-negotiable for fabricating advanced semiconductor devices and other nanoscale technologies.

The Speed of CVD

The main benefit of CVD is its speed and efficiency, which translates to higher throughput and often lower cost. It is the workhorse for many industrial applications where thick, functional coatings are needed without atomic-level specifications.

Material and Process Complexity

CVD technology is generally more mature, with a wider range of established precursors and processes for various materials. Developing a new ALD process can be more complex and time-consuming due to the precise requirements of its self-limiting chemistry.

Making the Right Choice for Your Application

Your decision will be dictated by the specific technical and economic requirements of your project.

- If your primary focus is ultrathin, perfectly uniform films on complex 3D structures: ALD is the superior and often the only viable choice due to its atomic-level control.

- If your primary focus is depositing thicker films quickly and economically: CVD offers the necessary speed, efficiency, and scalability for the job.

- If your project requires a balance of good coverage and reasonable speed: CVD is frequently the more practical and cost-effective starting point for films thicker than 50-100 nm.

Understanding this fundamental difference between sequential precision and continuous speed empowers you to select the optimal deposition technique for your goal.

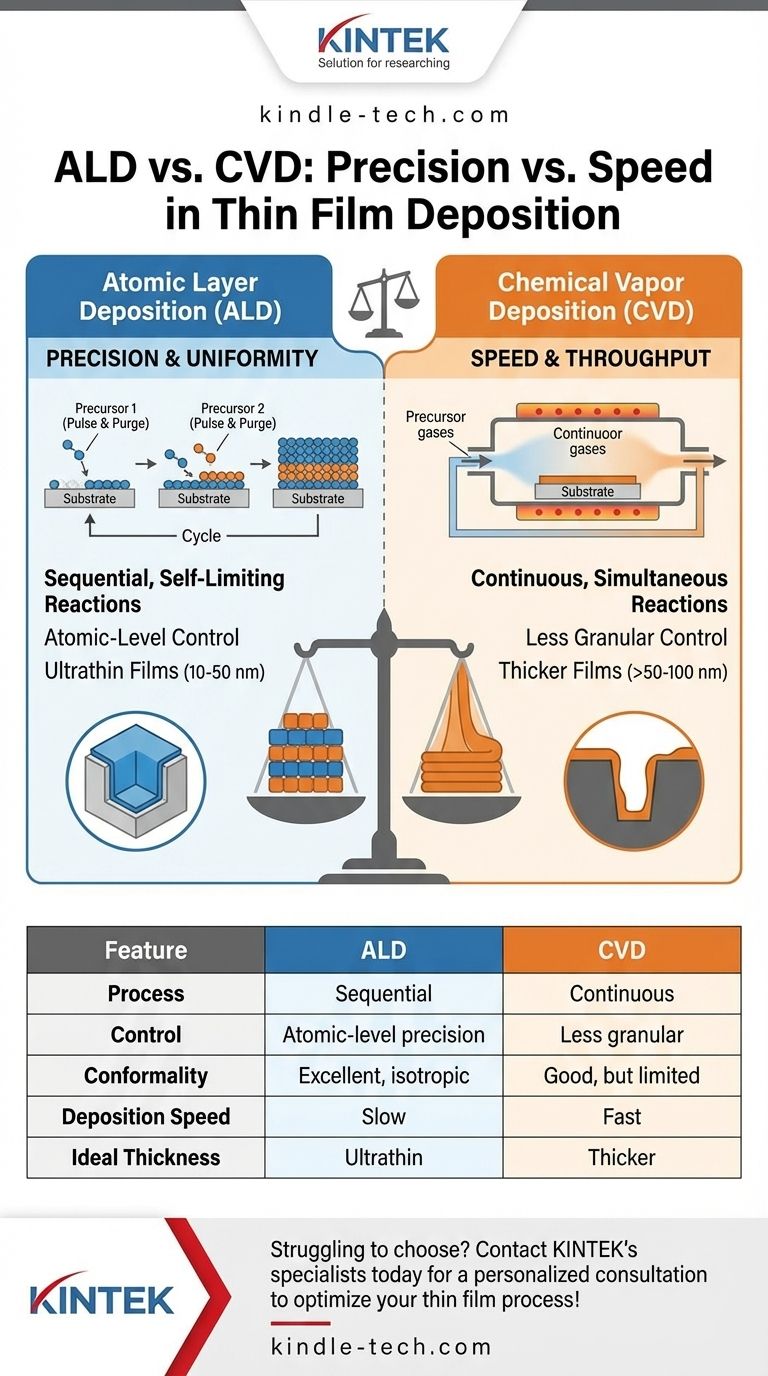

Summary Table:

| Feature | Atomic Layer Deposition (ALD) | Chemical Vapor Deposition (CVD) |

|---|---|---|

| Process | Sequential, self-limiting reactions | Continuous, simultaneous reactions |

| Control | Atomic-level precision | Less granular control |

| Conformality | Excellent, isotropic (uniform on complex 3D structures) | Good, but can struggle with high-aspect-ratio structures |

| Deposition Speed | Slow (layer-by-layer) | Fast (continuous) |

| Ideal Film Thickness | Ultrathin films (10-50 nm) | Thicker films (>50-100 nm) |

| Primary Advantage | Precision and uniformity | Speed and throughput |

Struggling to choose the right deposition technique for your lab's specific needs? The choice between ALD's atomic-level precision and CVD's high-speed deposition is critical for your research and production outcomes. At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to your laboratory's unique requirements. Our experts can help you select the ideal system to achieve perfect film uniformity or maximize your throughput. Let's optimize your thin film process together – contact our specialists today for a personalized consultation!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is chemical vapour deposition process? A Guide to High-Purity, Conformal Thin Films

- What is the role of substrate in CVD? The Blueprint for High-Quality Thin Films

- What are the advantages of low pressure CVD? Achieve Superior Film Uniformity and Purity

- What is the principle of CVD process? Growing High-Performance Materials from Gas

- What does the CVD stand for? A Guide to Chemical Vapor Deposition Technology

- What role does a resistance heating furnace play in CVD tantalum coating? Master Thermal Precision in CVD Systems

- What is vacuum vapor deposition of gold? A Guide to CVD vs. PVD Methods

- Why do we use chemical vapor deposition? For Unmatched Purity and Conformal Coatings