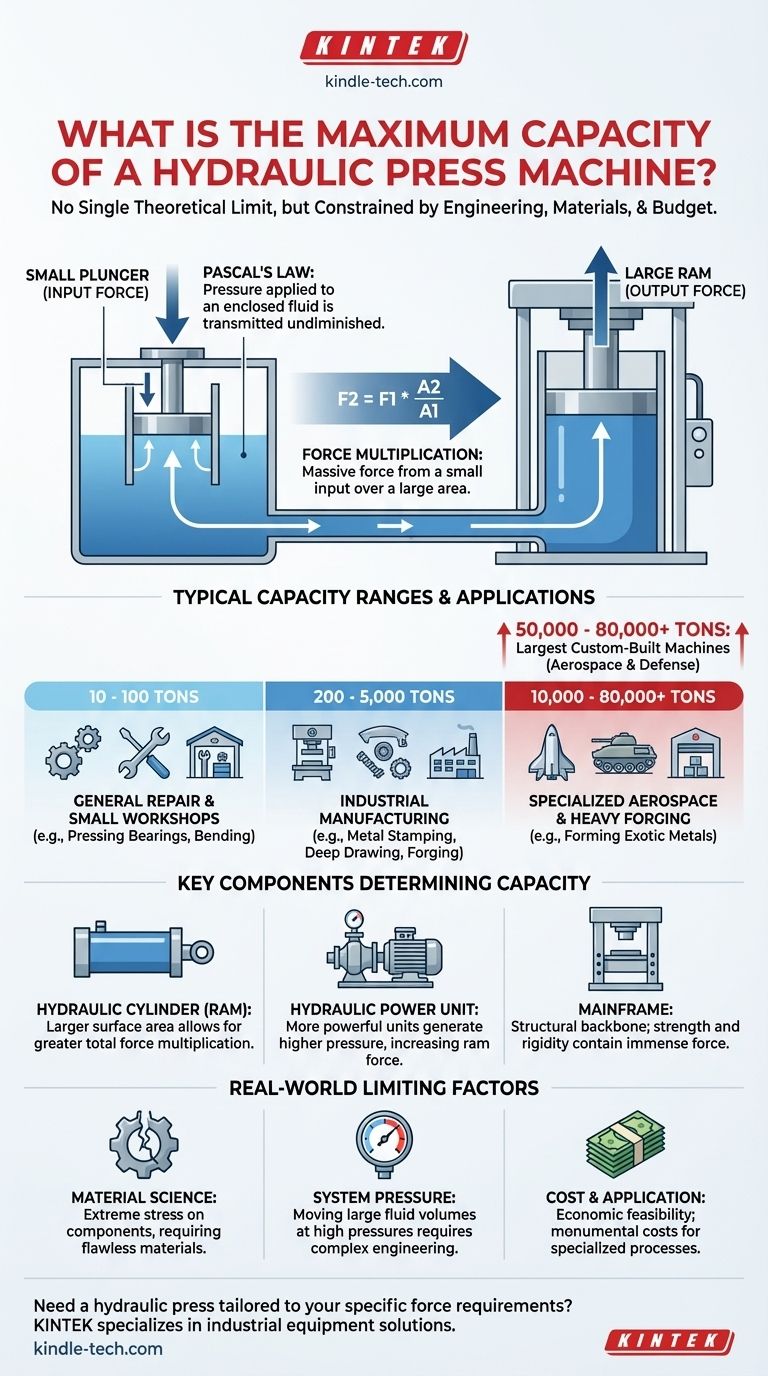

In short, there is no single theoretical maximum capacity for a hydraulic press machine. While common industrial presses range from 20 to 2,000 tons, the largest custom-built machines, designed for specialized aerospace and defense manufacturing, can exceed 50,000 and even approach 80,000 tons of force. The ultimate capacity is not a fixed limit of the technology but is instead constrained by engineering design, material science, and project budget.

The core principle to understand is that a hydraulic press's capacity is a function of its design, not an inherent technological ceiling. The immense force is achieved by multiplying a small initial force over a large area, a concept limited only by the strength of the materials used to build the machine and the power of its hydraulic system.

How Hydraulic Presses Achieve Immense Force

The remarkable capacity of a hydraulic press is not based on complex machinery with numerous moving parts, but on a straightforward principle of fluid dynamics. This simplicity is a key advantage, allowing for the generation of massive force in a relatively compact and efficient design.

The Core Principle: Pascal's Law

A hydraulic press operates on Pascal's Law, which states that pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

The system uses two interconnected cylinders of different sizes, each filled with hydraulic fluid. One cylinder, the Plunger, is smaller, while the larger one is known as the Ram.

When a small force is applied to the Plunger, it creates pressure in the fluid. This pressure acts equally across the entire system, including the much larger surface area of the Ram, multiplying the initial force exponentially.

Key Components That Determine Capacity

Several critical components work together to generate and contain this force. The design and robustness of these parts directly determine the press's maximum tonnage.

- Hydraulic Cylinder (Ram): The diameter of the Ram is the single most important factor. A larger surface area allows the system pressure to be multiplied into a greater total force.

- Hydraulic Power Unit: This includes the pump and motor that generate the high-pressure hydraulic fluid. A more powerful unit can create higher pressures, thus increasing the force generated by the Ram.

- Mainframe: This is the structural backbone of the press. Its strength and rigidity are paramount, as it must safely contain and oppose the immense force being generated by the hydraulic system without deforming.

Understanding the Real-World Limiting Factors

If the principle is simple, one might ask why we don't build million-ton presses. The answer lies in the practical challenges of engineering, materials, and cost that create a point of diminishing returns.

Material Science and Engineering

The sheer force generated by a large-tonnage press places incredible stress on its components. The mainframe must be massive and flawlessly constructed to avoid catastrophic failure. The seals within the hydraulic cylinder must withstand extreme pressures without leaking. The cost and complexity of manufacturing components of this size and strength are significant limitations.

System Pressure and Fluid Dynamics

Generating thousands of tons of force requires moving large volumes of hydraulic fluid at very high pressures. The pumps, valves, and piping must be engineered to handle this flow reliably and safely. As capacity increases, the power requirements and complexity of the hydraulic control system grow exponentially.

Cost and Application

Ultimately, the most significant limiting factor is economic. A 50,000-ton press is a monumental piece of infrastructure, costing hundreds of millions of dollars to build, install, and operate. Such an investment is only justifiable for a handful of highly specialized manufacturing processes, such as forging critical airframe components from titanium or high-strength alloys.

Making the Right Choice for Your Goal

The "maximum capacity" is less important than the appropriate capacity for a given task. Understanding the typical ranges helps put the numbers in context.

- If your primary focus is general repair or a small workshop: Presses in the 10 to 100-ton range offer more than enough force for tasks like pressing bearings, bending metal, or custom fabrication.

- If your primary focus is industrial manufacturing: Presses from 200 to 5,000 tons are common for processes like metal stamping, deep drawing, forging, and molding.

- If your primary focus is specialized aerospace or heavy forging: Capacities exceeding 10,000 tons are required for forming large, single-piece components from exotic metals.

The true strength of hydraulic press technology lies in its remarkable scalability to meet nearly any industrial need.

Summary Table:

| Typical Use Case | Common Capacity Range |

|---|---|

| General Repair & Small Workshops | 10 - 100 tons |

| Industrial Manufacturing (Stamping, Forging) | 200 - 5,000 tons |

| Specialized Aerospace & Heavy Forging | 10,000 - 80,000+ tons |

Need a hydraulic press tailored to your specific force requirements? KINTEK specializes in industrial equipment solutions, providing reliable hydraulic presses for workshops, manufacturing facilities, and specialized applications. Our experts will help you select the perfect machine to enhance your productivity and precision. Contact us today to discuss your project needs!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis