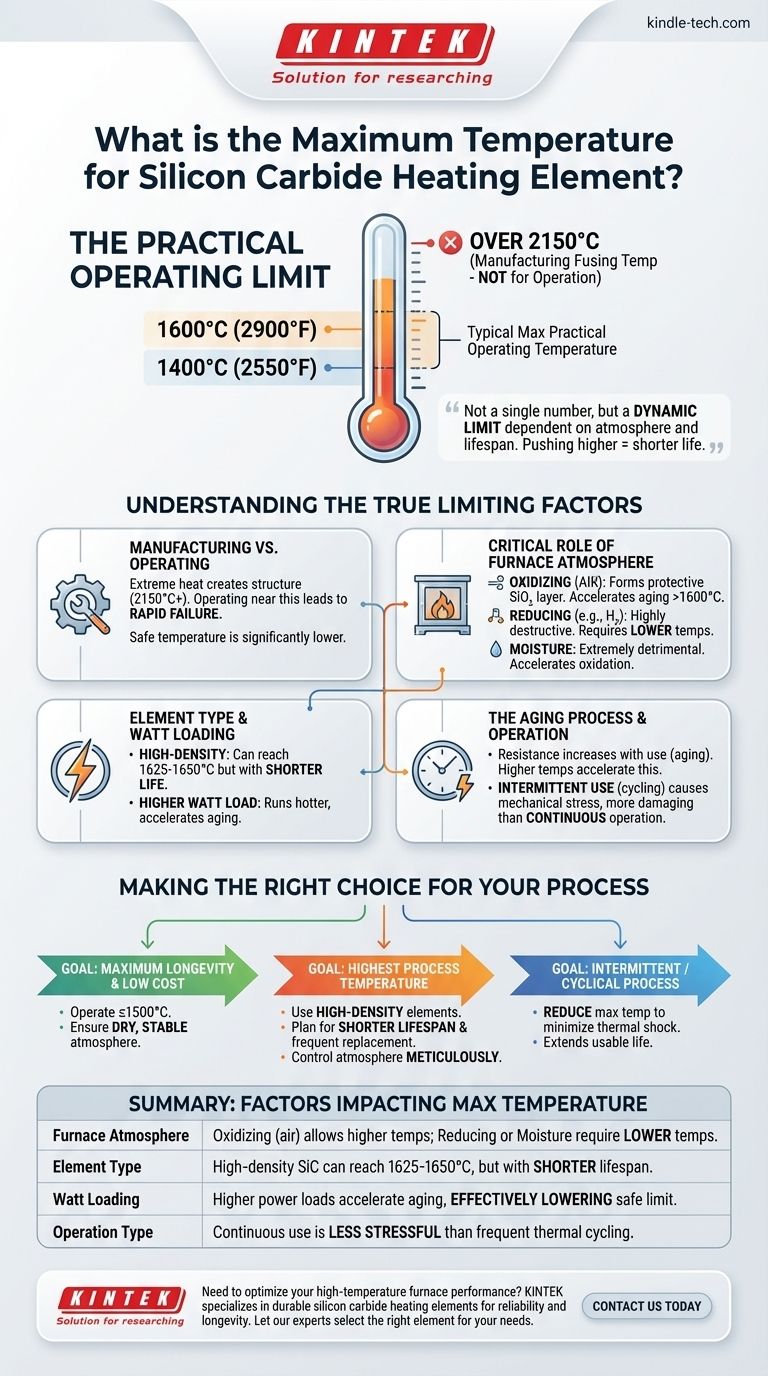

The maximum practical operating temperature for a standard silicon carbide (SiC) heating element is typically between 1400°C and 1600°C (2550°F to 2900°F). While the material itself is fused at over 2150°C during manufacturing, operating anywhere near this temperature is impossible and will lead to immediate failure. The element's true maximum temperature is determined by the furnace atmosphere, its power load, and your tolerance for a shortened lifespan.

The maximum temperature of a silicon carbide heating element is not a single number, but a dynamic limit heavily dependent on the furnace atmosphere and desired element lifespan. Pushing for higher temperatures almost always results in a significantly shorter operational life.

Understanding the True Limiting Factors

To operate a high-temperature furnace effectively, you must understand the variables that dictate the element's performance and longevity. The catalog number is only the beginning of the story.

The Difference Between Manufacturing and Operating Temperature

The reference to fusing SiC grains at over 2150°C describes the manufacturing process, not the operational limit. This extreme temperature creates the element's strong, recrystallized structure.

Attempting to operate an element near this temperature would cause rapid degradation and failure. The safe operating temperature is always significantly lower.

The Critical Role of Furnace Atmosphere

The environment inside the furnace is the single most important factor determining the element's maximum safe temperature and lifespan.

-

In an oxidizing atmosphere (like air): The element forms a thin, protective layer of silicon dioxide (SiO₂). This layer is what allows it to survive at high temperatures, but it also slowly increases the element's electrical resistance over time—a process known as aging. At extreme temperatures (above 1600°C), this process accelerates dramatically.

-

In a reducing atmosphere (like hydrogen): These atmospheres can be highly destructive to SiC elements and require you to significantly lower the maximum operating temperature.

-

Presence of Water Vapor: Moisture is extremely detrimental. It accelerates the oxidation process, leading to premature aging and failure. A dry atmosphere is critical for longevity.

Element Type and Watt Loading

Different grades of SiC elements exist. High-density elements are designed to better withstand high temperatures and can sometimes be pushed to 1625°C or even 1650°C, but always at the cost of a shorter life.

Watt loading—the amount of power dissipated per square centimeter of the element's surface—also plays a key role. Higher watt loads make the element run hotter, which accelerates aging and shortens its life, even if the furnace's chamber temperature is the same.

Understanding the Trade-offs: Temperature vs. Lifespan

Every decision about operating temperature is a trade-off between process speed and equipment cost. Understanding these compromises is essential for efficient and predictable furnace operation.

The Aging Process

All SiC elements age. Their electrical resistance gradually increases with use, especially at high temperatures. To maintain the same heat output, you must steadily increase the voltage supplied to the element.

Running an element at its absolute maximum temperature dramatically accelerates this aging. You may reach the end of your power supply's voltage range much faster, forcing a costly replacement.

Continuous vs. Intermittent Operation

Thermal cycling is a major source of stress. Heating an element from room temperature to its operating point and back down again (intermittent use) is often more damaging than running it continuously at a stable high temperature.

Each cycle introduces mechanical stress as the material expands and contracts. If your process requires frequent cycling, you may benefit from operating at a more conservative temperature to prolong element life.

Making the Right Choice for Your Process

There is no single "best" temperature; there is only the best temperature for your specific goal. Use these guidelines to make an informed decision.

- If your primary focus is maximum element longevity and low cost: Operate your elements at or below 1500°C and ensure your furnace atmosphere is dry and stable.

- If your primary focus is achieving the highest possible process temperature: Use high-density SiC elements, plan for a significantly shorter lifespan and higher replacement frequency, and meticulously control the furnace atmosphere.

- If your primary focus is running an intermittent or cyclical process: Reduce your maximum operating temperature to minimize the thermal shock from each cycle, which will extend the element's usable life.

Ultimately, treating the maximum temperature as a hard limit to be avoided, rather than a target to be reached, is the key to reliable and cost-effective operation.

Summary Table:

| Factor | Impact on Maximum Temperature |

|---|---|

| Furnace Atmosphere | Oxidizing (air) allows higher temps; reducing atmospheres or moisture require lower temps. |

| Element Type | High-density SiC can reach 1625-1650°C, but with a shorter lifespan. |

| Watt Loading | Higher power loads accelerate aging, effectively lowering the safe operating limit. |

| Operation Type | Continuous use is less stressful than frequent thermal cycling (intermittent use). |

Need to optimize your high-temperature furnace performance? KINTEK specializes in lab equipment and consumables, including durable silicon carbide heating elements designed for reliability and longevity. Our experts can help you select the right element for your specific furnace atmosphere and temperature requirements, ensuring cost-effective and efficient operation. Contact us today to discuss your laboratory heating needs!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

People Also Ask

- How do multiple cartridge heaters and K-type thermocouples work together? Achieve Optimal Temperature Uniformity

- How does a heating element heat up? The Science of Joule Heating Explained

- What is a thermocouple and how does it function in a sintering furnace? Master Precise High-Temp Control

- What is the advantage of molybdenum? Unlock Superior High-Temperature Performance

- What should heating element be made of? A Guide to High-Temp, Durable Materials

- How are PTC cartridge heaters used? Self-Regulating Precision for Direct Immersion and Contact Heating

- How does an electric oven heating element work? The Science of Resistive Heating Explained

- What is the best material for high temperature furnace elements to be used in oxidizing atmospheres? Choose the Right Element for Your Lab