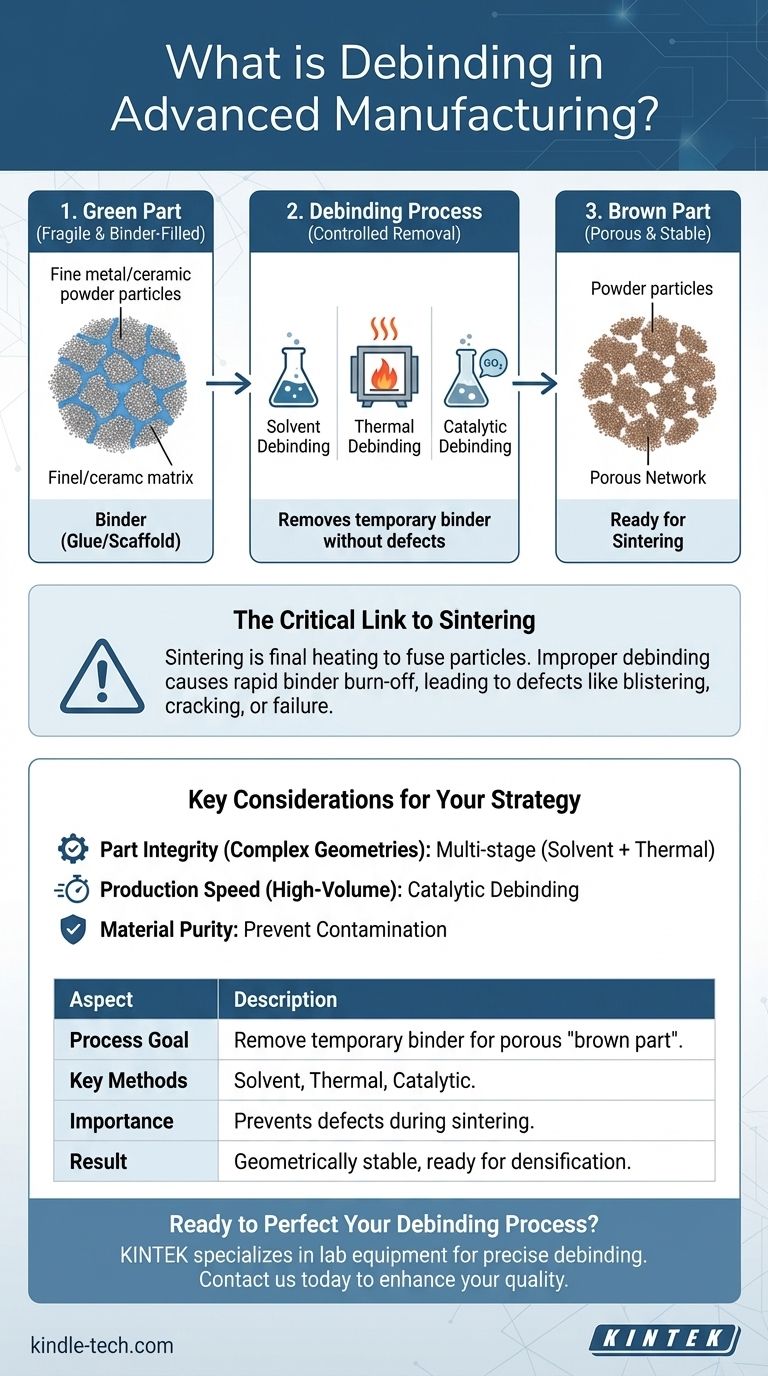

In advanced manufacturing, debinding is the critical process of systematically removing the temporary binding material, or "glue," from a newly molded or printed component. This component, known as a "green part," is a fragile mixture of fine metal or ceramic powder held together by this binder. Debinding carefully prepares the part for the final, high-temperature sintering stage where it gains its final strength and density.

The core purpose of debinding is to transform a fragile, binder-filled "green part" into a porous but geometrically stable "brown part." This transition must be executed perfectly to avoid defects, as the success of the entire manufacturing process hinges on the complete and controlled removal of this temporary scaffold.

The Role of the Binder: From Powder to "Green" Part

Why Binders are Necessary

Fine metal or ceramic powders cannot hold a complex shape on their own. They behave more like sand than a solid.

A binder, typically a mixture of polymers, waxes, and other agents, acts as a temporary scaffold. It allows the powder to be precisely molded, extruded, or printed into a detailed shape, creating what is known as the green part.

The Composition of the "Green" Part

The green part is mostly composed of the final metal or ceramic powder, but a significant portion of its volume is the binder system. This binder provides handling strength but must be removed before the final step.

The Debinding Process: From "Green" to "Brown" Part

The Core Objective: Controlled Removal

The primary goal of debinding is to extract the binder from the green part without causing any swelling, cracking, or distortion.

As the binder is removed, it leaves behind a network of pores between the powder particles. The resulting component is called the brown part, which is highly porous and very fragile.

Common Debinding Methods

Debinding is rarely a single action. As the reference material notes, it often involves multiple cycles or methods to remove different components of the binder system.

- Solvent Debinding: The green part is immersed in a solvent bath that dissolves and leaches out a significant portion of the binder. This is often the first step, creating an open-pore network for subsequent stages.

- Thermal Debinding: The part is heated slowly in a controlled-atmosphere furnace. The heat breaks down and evaporates the remaining binder material. This must be done gradually to prevent rapid gas buildup, which can damage the part.

- Catalytic Debinding: This method uses a gaseous catalyst (often an acid) to chemically decompose the binder at lower temperatures than thermal debinding. This can significantly speed up the process.

The Critical Link to Sintering

Why Debinding is Essential

Sintering is the final manufacturing step, where the brown part is heated to a temperature near the melting point of the powder. At this temperature, the individual particles fuse together, eliminating the pores and densifying the part to its final, solid state.

The Consequences of Improper Debinding

If any significant amount of binder remains when the part enters the high-temperature sintering furnace, it will burn off very rapidly.

This rapid outgassing creates immense internal pressure, leading to severe defects like blistering, cracking, distortion, or even complete failure of the component. Therefore, a thorough debinding process is non-negotiable for producing a quality part.

Key Considerations for Your Debinding Strategy

Choosing the right debinding strategy depends entirely on your material, part geometry, and production goals.

- If your primary focus is part integrity for complex geometries: A multi-stage process, like combining solvent and slow thermal debinding, is often the safest approach to prevent stress and distortion.

- If your primary focus is high-volume production speed: Catalytic debinding is typically the fastest method, but it requires a compatible binder system and specialized equipment.

- If your primary focus is material purity: You must ensure the chosen debinding method (especially solvents) does not contaminate or react negatively with the fine metal or ceramic powder.

Ultimately, understanding debinding is crucial for anyone looking to transform a precisely shaped powder-based component into a robust, high-performance final product.

Summary Table:

| Aspect | Description |

|---|---|

| Process Goal | Remove temporary binder material from a "green part" to create a porous "brown part." |

| Key Methods | Solvent Debinding, Thermal Debinding, Catalytic Debinding. |

| Importance | Prevents defects like blistering and cracking during the final sintering stage. |

| Result | A geometrically stable part ready for high-temperature densification. |

Ready to Perfect Your Debinding Process?

Choosing the right debinding strategy is critical for the integrity and performance of your final parts. KINTEK specializes in providing the lab equipment and consumables necessary for precise thermal and catalytic debinding, ensuring your metal or ceramic components are perfectly prepared for sintering.

Contact us today to discuss your specific manufacturing needs and discover how our solutions can enhance your production quality and efficiency.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the difference between a box furnace and a muffle furnace? Choose the Right Lab Furnace for Your Application

- What is a furnace used in the lab? Your Guide to High-Temperature Precision

- What are the disadvantages of a muffle furnace? Understanding the Trade-offs for Your Lab

- What is maintenance and how can you maintain the laboratory? Boost Lab Reliability & Data Integrity

- How accurate is the muffle furnace? Achieve ±1°C Control and ±2°C Uniformity