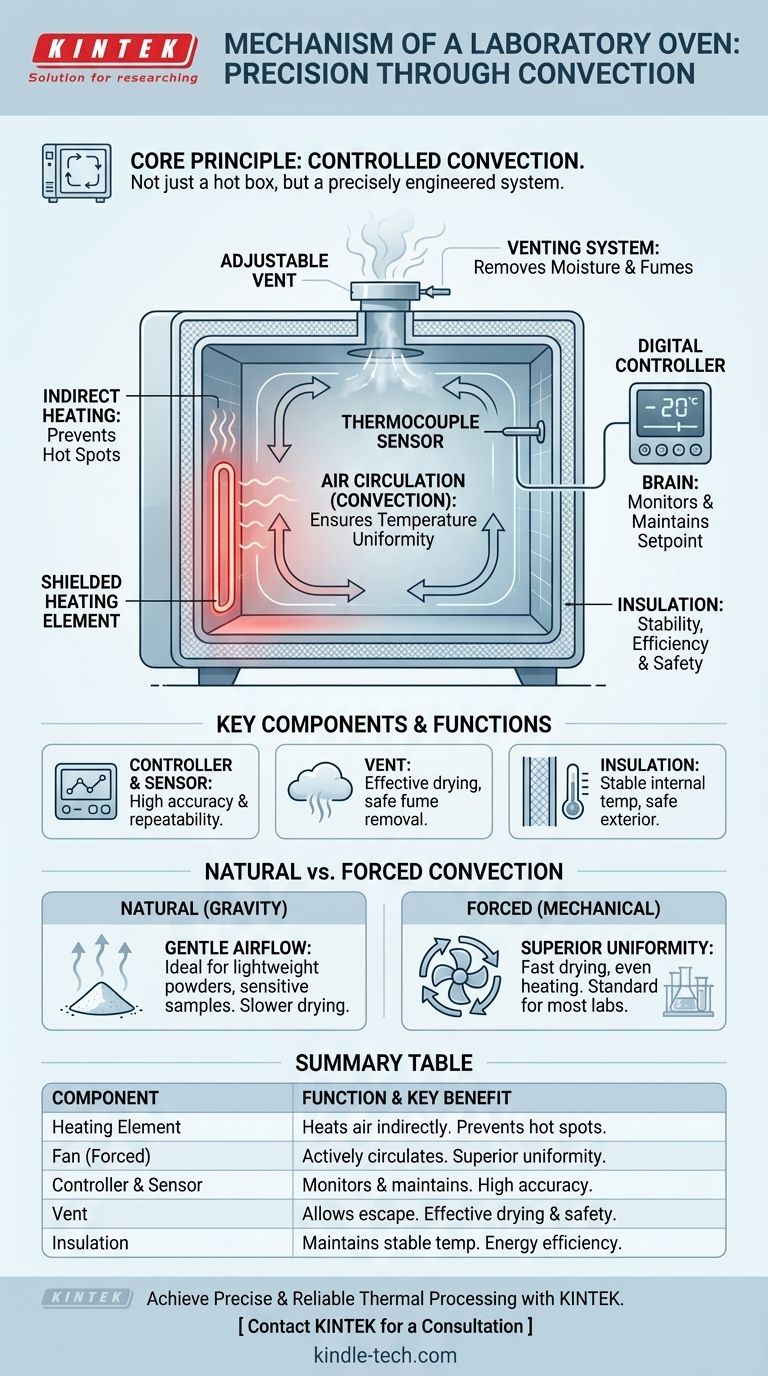

At its core, a laboratory oven operates by using an internal heating element combined with a method of air circulation to create a precisely controlled and uniform thermal environment. This process, known as convection, allows for the effective drying, sterilizing, or thermal testing of materials without subjecting them to the harsh, uneven effects of direct radiant heat. A crucial part of this mechanism is a vent, which allows moisture and fumes to escape the chamber.

A laboratory oven isn't simply a box that gets hot. Its mechanism is a precisely engineered system that combines controlled heating with air circulation (convection) to achieve temperature uniformity, while a dedicated vent actively removes moisture to ensure tasks like drying and sterilization are performed effectively and safely.

The Core Principle: Convection Heating

The defining mechanism of a laboratory oven is convection. This method is vastly superior to simple radiant heating (like an open fire or a basic toaster) for scientific applications because it ensures every item in the oven experiences the same temperature.

The Heating Element's Role

The process begins with an electric heating element. These elements are typically located in the oven's walls or in a separate compartment, intentionally separated from the main chamber to prevent direct line-of-sight radiation onto the samples. This prevents "hot spots" and ensures the air is heated, not the sample directly.

The Importance of Air Circulation

Once the air is heated, it must be circulated throughout the chamber. This is the "convection" part of the process and is what guarantees temperature uniformity. Without circulation, you would have layers of hot and cool air, leading to unreliable results.

Achieving Temperature Uniformity

The combination of a shielded heating element and active air circulation ensures that whether a sample is on the top shelf or the bottom, it is exposed to the exact same thermal conditions. This uniformity is critical for repeatable experiments and reliable sterilization.

Key Components and Their Function

Several components work in concert to execute the oven's primary function. Understanding each part reveals why a lab oven is a precision instrument.

The Controller and Thermocouple

The "brain" of the oven is its temperature controller. It receives a constant reading from a sensor, typically a thermocouple, located inside the chamber. The controller compares this real-time temperature to the user's setpoint and cycles the heating element on and off to maintain that temperature with high accuracy.

The Venting System

Unlike a kitchen oven, a lab oven has an adjustable vent. Its purpose is twofold: first, to allow moisture to escape. As samples dry, water vapor is released. Without a vent, this would create a high-humidity environment, defeating the purpose of drying. Second, it allows for the safe removal of any fumes or volatile organic compounds (VOCs) that may be released during heating.

Insulation

High-quality insulation is critical. It ensures the temperature inside the chamber remains stable and is not influenced by ambient room temperature. It also improves energy efficiency and keeps the oven's exterior surfaces safe to touch.

Understanding the Trade-offs: Natural vs. Forced Convection

Not all lab ovens circulate air in the same way. The method of convection is a key differentiator that impacts performance and suitability for different tasks.

Natural Convection (Gravity Ovens)

These ovens do not use a fan. They rely on the natural principle that hot air is less dense and rises, while cooler air sinks. This gentle air movement is ideal for drying delicate samples, such as fine powders, that could be disturbed or blown away by a fan. However, their temperature uniformity and heat-up times are inferior to forced-air models.

Forced Convection (Mechanical Ovens)

These ovens use a fan to actively circulate the heated air throughout the chamber. This provides superior temperature uniformity and significantly reduces drying times because the moving air constantly strips away the layer of moist air surrounding the samples. This is the standard for most sterilization and testing applications.

How This Applies to Your Application

Choosing and using an oven correctly depends entirely on your scientific goal.

- If your primary focus is fast, uniform drying or sterilization: A forced convection oven is the superior choice because its fan accelerates moisture removal and guarantees even heating.

- If your primary focus is processing lightweight powders or samples sensitive to airflow: A natural (gravity) convection oven is necessary to prevent your samples from being disturbed.

- If your primary focus is safety when heating materials that release fumes: You must use an oven with an adequate vent and ensure it is properly exhausted, regardless of the convection type.

Understanding these core mechanisms empowers you to select and operate the right tool for precise and repeatable results.

Summary Table:

| Component | Function | Key Benefit |

|---|---|---|

| Heating Element | Heats air indirectly | Prevents hot spots on samples |

| Fan (Forced Convection) | Actively circulates heated air | Ensures superior temperature uniformity |

| Controller & Thermocouple | Monitors and maintains set temperature | Provides high accuracy and repeatability |

| Vent | Allows moisture and fumes to escape | Enables effective drying and ensures safety |

| Insulation | Maintains stable chamber temperature | Improves energy efficiency and safety |

Ready to achieve precise and reliable thermal processing in your lab?

The correct laboratory oven is critical for consistent drying, sterilization, and testing results. At KINTEK, we specialize in providing high-quality lab equipment, including a range of convection ovens tailored to your specific needs—whether you require the gentle drying of a natural convection model or the fast, uniform performance of a forced-air system.

Let our experts help you select the perfect oven to enhance your lab's efficiency and safety.

Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Scientific Electric Heating Blast Drying Oven

- 1200℃ Muffle Furnace Oven for Laboratory

- 50L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 30L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 20L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

People Also Ask

- Why is a laboratory-grade forced air drying oven required for alloy chip moisture analysis? Ensure Data Precision

- How does a controlled drying process ensure the quality of radiochromic films? Achieve Precise Dosimetric Results

- What is the primary purpose of using an electric drying oven for dense refractory bricks? Optimize Raw Material Prep

- What is the function of a laboratory oven in W18Cr4V steel sample preparation? Expert Microstructural Drying Guide

- Why is a forced-air drying oven required for ZnS powder? Protect Sintered Ceramics from Cracking