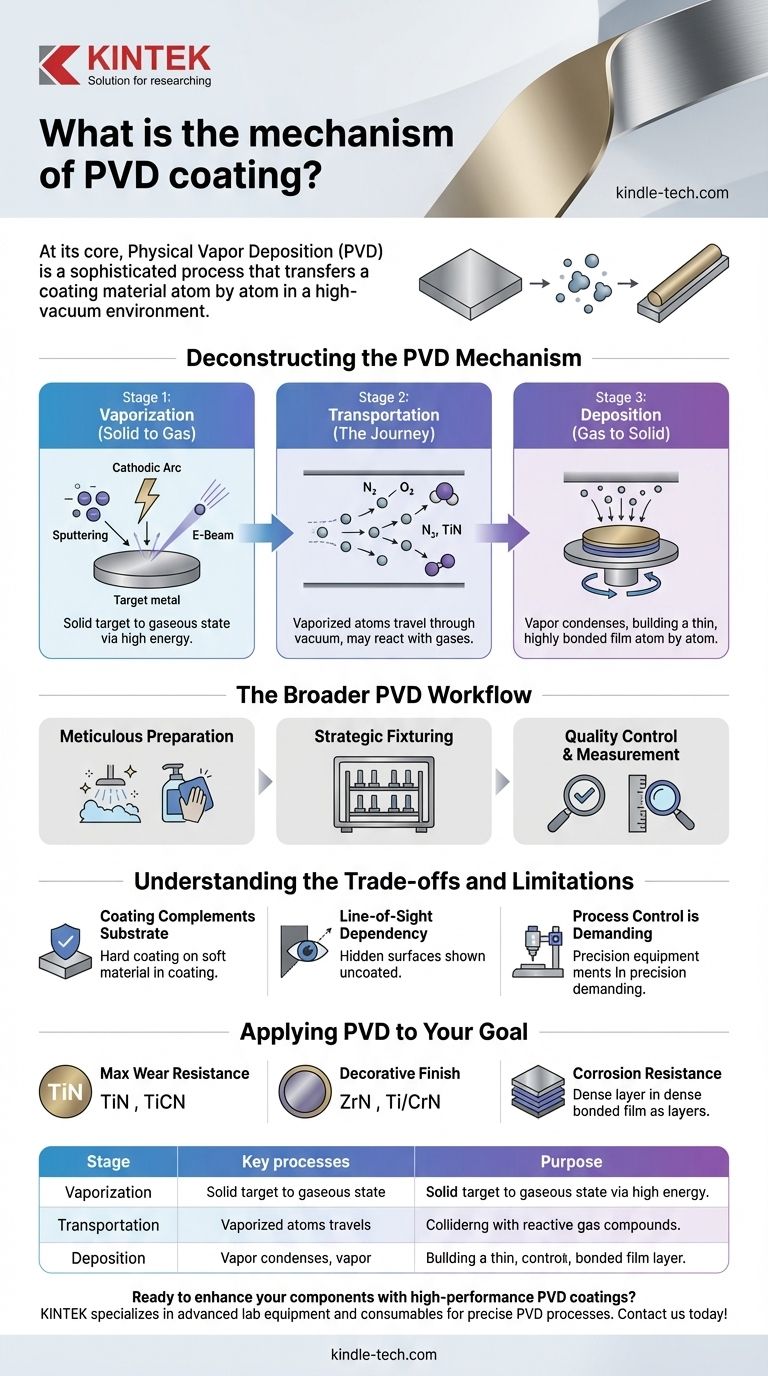

At its core, Physical Vapor Deposition (PVD) is a sophisticated process that transfers a coating material atom by atom. It works by taking a solid material, vaporizing it in a high-vacuum environment, and then depositing it onto the surface of a component. This method creates an extremely thin, hard, and strongly bonded film with properties superior to the underlying material.

The central mechanism of PVD involves transforming a solid into a vapor within a vacuum, which ensures purity, and then condensing that vapor onto a target part. This atom-by-atom deposition creates a dense, durable coating that is physically interlocked with the part's surface.

Deconstructing the PVD Mechanism

To truly understand PVD, we must break it down into its three fundamental physical stages, all of which occur inside a sealed vacuum chamber. The vacuum is not a passive element; it is critical for the success of the process.

The Critical Role of the Vacuum

The entire process is performed at a very low pressure. This is done to remove air and other gas particles that would otherwise react with or impede the vaporized coating material. A clean, empty environment is essential for achieving a pure, dense coating with powerful adhesion.

Stage 1: Vaporization (Solid to Gas)

The process begins with a solid, high-purity coating material known as a target. This target is subjected to high energy to force its atoms to transition into a gaseous state, or vapor.

Common vaporization methods include:

- Sputtering: An ion beam (often from a plasma) bombards the target, physically knocking atoms loose.

- Cathodic Arc: A high-current electric arc moves across the target surface, vaporizing the material in its path.

- Electron-Beam: A focused beam of high-energy electrons heats and vaporizes the material in a crucible.

Stage 2: Transportation (The Journey)

Once vaporized, the atoms or ions of the coating material travel through the vacuum chamber. Their path is directed toward the parts to be coated, which are strategically placed on rotating fixtures to ensure even exposure.

During this stage, a reactive gas like nitrogen or oxygen may be introduced. The vaporized metal atoms react with this gas mid-flight, forming a ceramic or metal-ceramic compound that will become the final coating. For example, vaporized titanium (Ti) reacting with nitrogen (N₂) forms the hard, gold-colored Titanium Nitride (TiN).

Stage 3: Deposition (Gas to Solid)

When the vaporized atoms reach the surface of the component (known as the substrate), they condense, changing back into a solid state. This happens atom by atom, building up a thin film that is typically only a few microns thick. Because of the energy involved and the clean environment, this film becomes tightly bonded to the substrate's surface, creating a new, highly durable exterior.

The Broader PVD Workflow

The core mechanism is just one part of a larger industrial process. Success depends equally on the steps taken before and after the component enters the vacuum chamber.

Meticulous Preparation is Non-Negotiable

The final coating will only adhere properly to a perfectly clean surface. This preparatory stage often involves stripping any previous coatings, intensive multi-stage cleaning to remove all oils and residues, and sometimes a specific pre-treatment to enhance adhesion.

Strategic Fixturing

Parts must be carefully mounted on specialized racks or fixtures inside the chamber. The goal is to expose all critical surfaces to the vapor stream, as PVD is largely a "line-of-sight" process. Poor fixturing leads to uneven or incomplete coating.

Quality Control and Measurement

After the coating cycle, parts undergo strict quality control. This includes visual inspection for cosmetic uniformity and specialized measurements to confirm the coating's thickness and adhesion meet the required specifications.

Understanding the Trade-offs and Limitations

While powerful, PVD is not a magical solution. Understanding its limitations is key to using it effectively.

The Coating Complements the Substrate

A PVD coating enhances the surface properties of a part, but it does not change the core characteristics of the base material. For instance, an extremely hard TiN coating on a soft aluminum substrate will protect against scratches, but a heavy impact can still dent the underlying aluminum, causing the coating to fail.

Line-of-Sight Dependency

Most PVD processes cannot "coat around corners." Surfaces that are hidden or in deep recesses may receive little to no coating material. This is why part geometry and careful fixturing are critical considerations during the design phase.

Process Control is Demanding

The final properties of the coating are highly sensitive to process parameters like temperature, vacuum pressure, and the precise composition of reactive gases. Achieving consistent, high-quality results requires significant investment in equipment and deep process expertise.

Applying PVD to Your Goal

The right approach to PVD depends entirely on your primary objective for the component.

- If your primary focus is maximum wear and abrasion resistance: Prioritize hard coating materials like Titanium Nitride (TiN) or Titanium Carbonitride (TiCN) and ensure your substrate is also hard enough to support the coating under load.

- If your primary focus is a decorative or colored finish: Select materials like Zirconium Nitride (ZrN) for a pale gold color or Titanium/Chromium Nitride for other finishes, and insist on flawless surface preparation for a pristine look.

- If your primary focus is corrosion resistance: The key is a dense, defect-free coating layer, which requires precise process control and meticulous cleaning to prevent any points of failure.

Ultimately, PVD is a premier surface engineering tool that grants materials properties they could not otherwise achieve, provided its mechanism and operational requirements are fully respected.

Summary Table:

| PVD Mechanism Stage | Key Process | Purpose |

|---|---|---|

| 1. Vaporization | Sputtering, Cathodic Arc, E-Beam | Transform solid target material into a vapor. |

| 2. Transportation | Travel through vacuum, react with gases (e.g., N₂) | Direct vapor to substrate, form compounds (e.g., TiN). |

| 3. Deposition | Condensation on substrate surface | Build a thin, hard, strongly bonded coating atom by atom. |

Ready to enhance your components with high-performance PVD coatings? KINTEK specializes in advanced lab equipment and consumables for precise PVD processes. Whether you need wear-resistant, decorative, or corrosion-resistant coatings, our solutions ensure superior adhesion and durability. Contact us today to discuss how our expertise can optimize your surface engineering goals!

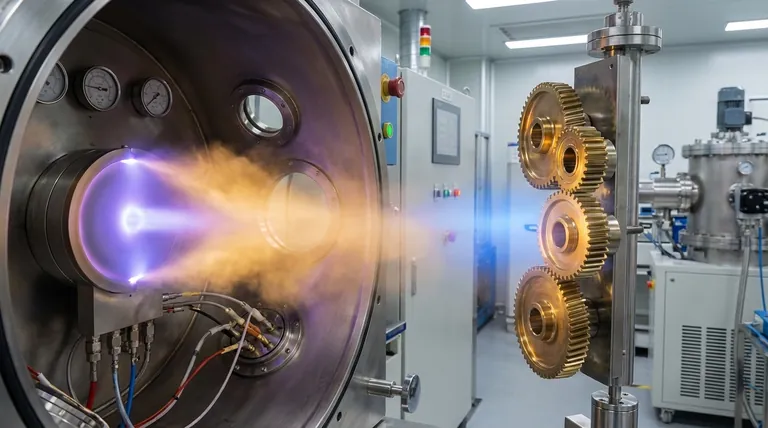

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What are the advantages and disadvantages of hot stamping? Unlock Ultra-High Strength for Automotive Parts

- How does hot pressing work? Achieve Maximum Density for Advanced Materials

- What is hot press forging? Creating Complex, High-Strength Metal Components

- What are the advantages and disadvantages of hot pressing? Choose the Right Powder Metallurgy Process

- What is the advantage by using hot press forming? Achieve Stronger, More Complex Parts