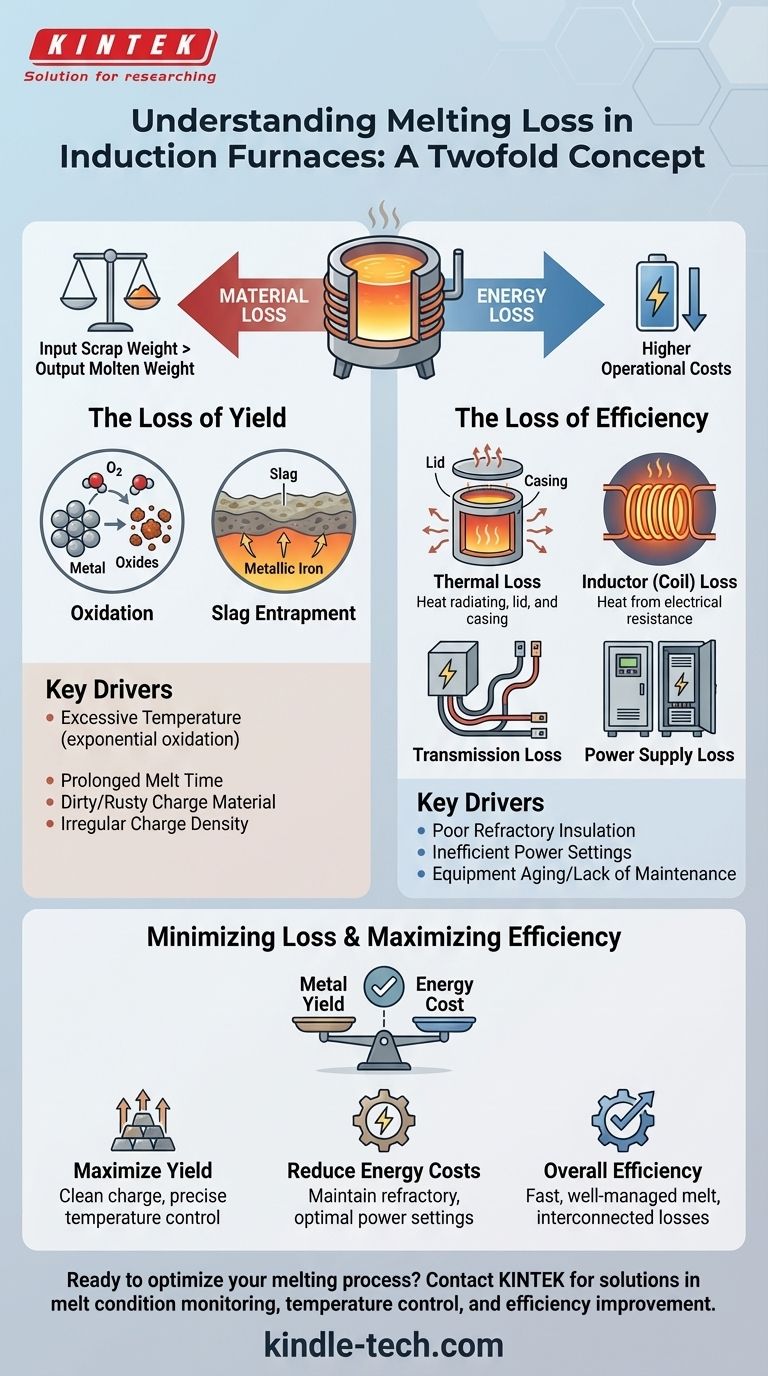

Melting loss in an induction furnace is a twofold concept that refers to both the physical loss of metal and the inefficient loss of energy during the melting process. While often used to describe the reduction in metal yield due to oxidation and slag formation, a complete understanding must also include the various forms of energy loss that increase operating costs and contribute indirectly to material loss.

The central challenge in furnace operation is that the very factors driving an efficient melt—high temperature and electromagnetic stirring—also accelerate the primary cause of material loss: oxidation. Your goal is not to eliminate these factors, but to control them precisely to convert the maximum amount of charged material into usable molten metal.

The Two Pillars of Melting Loss

To optimize your operation, you must distinguish between the two types of loss. One impacts your material yield, and the other impacts your energy bill.

Material Loss: The Loss of Yield

This is the most common meaning of "melting loss." It is the quantifiable difference between the weight of the solid metal charged into the furnace and the weight of the molten metal tapped out.

This loss primarily occurs through two mechanisms: oxidation and slag entrapment.

At the high temperatures reached in an induction furnace, which can exceed 2000°C, the metal charge reacts with oxygen from the atmosphere. This reaction forms metal oxides.

These oxides, along with other impurities from the scrap, form a layer of slag on top of the molten bath. While slag is necessary to refine the metal, excessive slag formation traps usable metallic iron, which is then removed and discarded, directly reducing your yield.

Energy Loss: The Loss of Efficiency

Energy loss does not reduce your metal yield directly, but it raises your operational costs. More importantly, an inefficient process extends the melting time, giving the metal more time to oxidize and thus increasing material loss.

The primary types of energy loss in an induction system include:

- Thermal Loss: Heat radiating from the molten metal, the furnace casing, and the lid.

- Inductor (Coil) Loss: Heat generated by the electrical resistance of the induction coil itself.

- Transmission Loss: Energy lost in the bus bars and cables connecting the power supply to the furnace.

- Power Supply Loss: Inefficiencies within the converter and inverter components of the power cabinet.

Key Factors That Drive Material Loss

Controlling material loss means managing the conditions of the melt. Several critical factors directly influence how much metal you lose to oxidation and slag.

Excessive Temperature

Oxidation rates increase exponentially with temperature. While you need to be hot enough to melt, every degree of "superheat" beyond the target tapping temperature accelerates the rate at which your valuable metal turns into oxide.

Prolonged Melt Time

The longer your metal bath is held at temperature, the more time it has to react with the atmosphere. A slow, inefficient melt will always have a higher material loss than a rapid, well-controlled one.

Charge Material Condition

The quality of your input material is critical. Using scrap that is dirty, oily, or excessively rusty introduces impurities and oxidants directly into the melt. This forces the creation of more slag to clean the metal, which in turn traps and removes more iron.

Irregular Charge Density

A poorly packed furnace with large voids between scrap pieces, as referenced by an "irregular distribution of the charge," is inefficient. It slows down energy transfer, prolongs the melt time, and can cause initial power supply issues, all of which contribute to higher overall losses.

Understanding the Trade-offs

Optimizing a furnace is a balancing act. Improving one metric can sometimes negatively affect another if not managed carefully.

Temperature vs. Speed

Increasing power input melts the charge faster, reducing the total melt time and potential for oxidation. However, this aggressive approach can easily lead to temperature overshooting, which wastes energy and accelerates oxidation at the end of the cycle.

Stirring vs. Oxidation

The electromagnetic field of an induction furnace inherently stirs the molten bath. This is excellent for temperature uniformity and alloy mixing. However, this same turbulence constantly brings new, unoxidized metal to the surface to react with the air.

Scrap Cost vs. Yield

Using low-cost, low-quality scrap may seem economical. However, the resulting increase in material loss from high impurity levels can often negate the initial savings, leading to a higher cost per ton of usable metal.

How to Minimize Melting Loss in Your Operation

Your strategy for minimizing loss will depend on your specific operational priorities.

- If your primary focus is maximizing metal yield: Prioritize using clean, dense, and appropriately sized charge material. Implement strict temperature control to avoid superheating.

- If your primary focus is reducing energy costs: Ensure your furnace refractory is in excellent condition to minimize thermal loss and run the equipment at its optimal power settings for a rapid, efficient melt cycle.

- If your primary focus is overall operational efficiency: View material and energy loss as interconnected. A fast, well-managed melt powered by a properly maintained system inherently reduces the window for oxidation to occur, thus preserving both energy and metal.

Ultimately, mastering your induction furnace is about achieving a rapid, efficient melt without unnecessary superheating, turning potential losses into profitable yield.

Summary Table:

| Type of Loss | Primary Cause | Key Impact |

|---|---|---|

| Material Loss | Oxidation & Slag Formation | Reduces final metal yield |

| Energy Loss | Thermal, Coil, & System Inefficiencies | Increases operational costs |

Ready to optimize your melting process and reduce losses?

At KINTEK, we specialize in lab equipment and consumables for metallurgical analysis and process optimization. Our solutions help you monitor melt conditions, control temperature, and improve efficiency—directly impacting your bottom line by maximizing yield and minimizing energy waste.

Contact our experts today to discuss how we can support your laboratory and foundry needs.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the primary function of a vacuum induction melting furnace? Melt High-Purity Metals with Precision

- What is the principle of vacuum induction melting? Achieve Ultra-High Purity Metals

- How does induction work in a vacuum? Achieve Ultra-Pure Metal Melting with VIM

- What is the difference between induction melting and vacuum induction melting? Choosing the Right Process for Purity

- What types of metals are typically processed in a vacuum induction melting furnace? High-Purity Alloys for Critical Applications