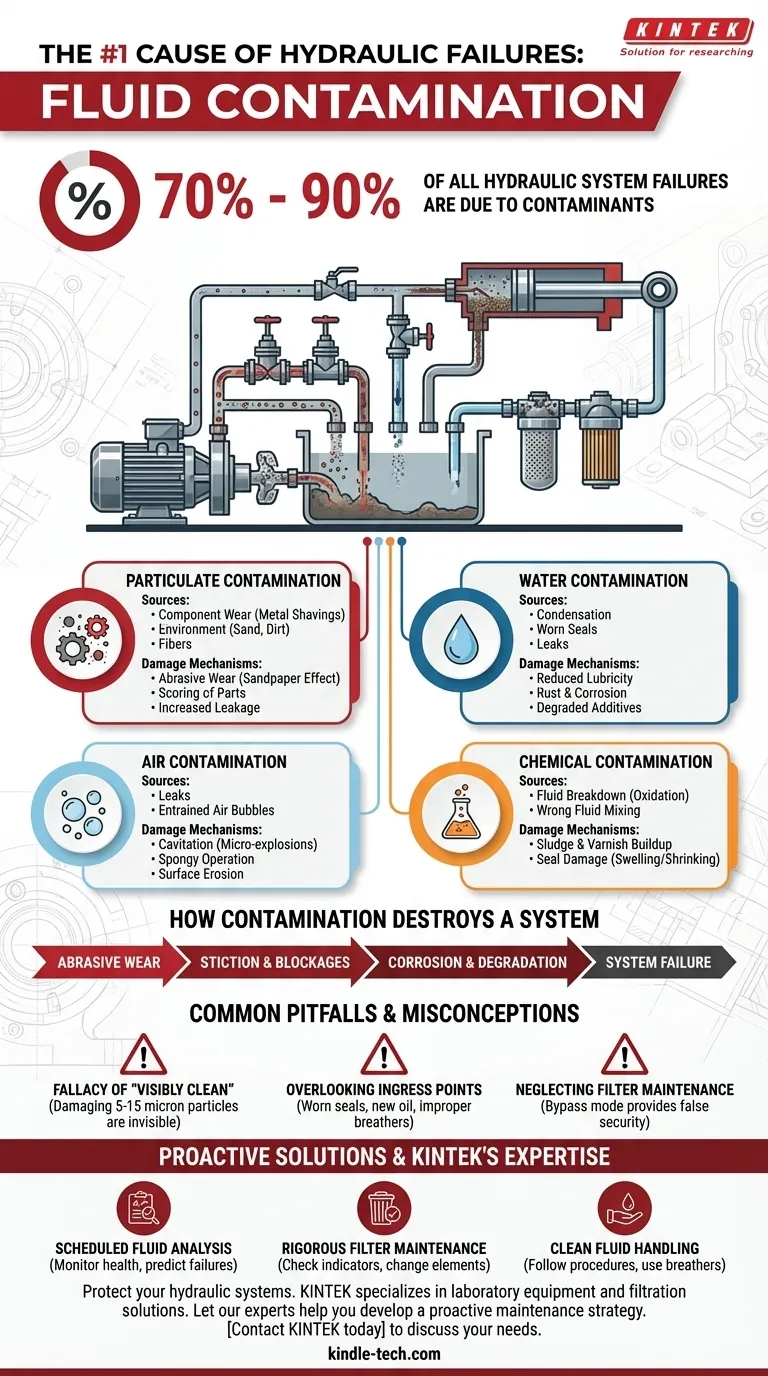

By a significant margin, the single most common cause of hydraulic system failure is fluid contamination. It is estimated to be responsible for 70% to 90% of all failures. This isn't limited to just dirt or metal shavings; it includes any foreign substance—such as water, air, or chemical byproducts—that compromises the hydraulic fluid's integrity and prevents the system from functioning as designed.

Hydraulic systems fail not from sudden, dramatic events, but from the slow, cumulative damage caused by contaminants that are often invisible to the naked eye. Proactive filtration and meticulous fluid management are the only effective strategies for ensuring reliability and longevity.

What Constitutes Hydraulic Contamination?

To effectively prevent failure, you must first understand what you are fighting against. Contamination is a broad term that covers several distinct and destructive categories of foreign substances within your hydraulic fluid.

Particulate Contamination

This is the most common and intuitive form of contamination. It includes solid particles like metal shavings from component wear, sand or dirt from the operating environment, and even fibers from rags or failing seals. These particles act like a liquid abrasive, grinding away at the system from the inside.

Water Contamination

Water is a particularly insidious contaminant. It often enters a system through condensation in the reservoir or through worn seals. Water reduces the lubricity of the hydraulic fluid, promotes rust and corrosion on metal surfaces, and can degrade fluid additives.

Air Contamination

Air can exist in two states: dissolved in the fluid (generally harmless) or entrained as bubbles (highly destructive). Entrained air leads to a phenomenon called cavitation, where air bubbles collapse under high pressure, creating micro-explosions that erode critical component surfaces, particularly within pumps. It also causes the fluid to become spongy, leading to erratic system operation.

Chemical Contamination

This occurs when the hydraulic fluid itself breaks down or when incorrect fluids are mixed. High temperatures can cause oxidation, creating sludge and varnish that clog narrow passages. Using the wrong type of fluid can cause seals to swell or shrink, leading to leaks and the introduction of other contaminants.

How Contamination Destroys a System

The damage caused by contamination is a progressive process. Understanding the specific mechanisms of failure highlights the importance of keeping the fluid clean.

Abrasive Wear: The Sandpaper Effect

Hard particles suspended in the fluid become trapped in the microscopic clearances between moving parts, such as a valve spool and its housing. This creates a "sandpaper" effect, scoring and wearing down these precision-machined surfaces. This gradual wear increases internal leakage, reducing the system's efficiency and eventually causing component failure.

Stiction and Blockages: Clogging the Arteries

Smaller, softer particles like sludge or seal fragments can build up in the system. They clog small orifices in components like servo and proportional valves, causing them to stick or respond slowly. This leads to inaccurate control, jerky operation, and ultimately, a complete loss of function.

Corrosion and Degradation: The Chemical Attack

Water and chemical contamination attack the system on a molecular level. They corrode metal surfaces, weakening parts and creating more particulate contamination (rust). They also break down the fluid itself, stripping it of the additives that provide lubrication and prevent foaming, accelerating overall system wear.

Common Pitfalls and Misconceptions

Many well-intentioned maintenance programs fail because of a few critical misunderstandings about contamination control.

The Fallacy of "Visibly Clean"

A major pitfall is assuming fluid is clean because it looks clean. The most damaging particles are those between 5 and 15 microns in size—far too small to be seen by the naked eye. A fluid can appear perfectly clear while containing millions of these destructive particles.

Overlooking Ingress Points

Contamination isn't just generated internally; it's constantly being introduced from the outside. Worn cylinder rod seals, contaminated new oil, and even just opening the reservoir to the air without a proper breather filter are all common ingress points that are often overlooked.

Neglecting Filter Maintenance

Filters are not a "set-it-and-forget-it" solution. A filter that is clogged and in bypass mode is providing a false sense of security. The oil is simply flowing around the filter element, circulating contaminants freely throughout the system. Regularly checking the filter's differential pressure indicator and changing elements is non-negotiable.

How to Apply This to Your System

Implementing a proactive strategy is the most effective way to reduce contamination-related failures and increase the reliability of your equipment.

- If your primary focus is maximizing equipment lifespan: Implement a scheduled fluid analysis program to monitor contaminant levels and fluid health, allowing you to predict and prevent failures.

- If your primary focus is preventing unexpected downtime: Focus on rigorous filter maintenance and ensure all technicians follow clean fluid handling procedures, especially when adding new oil to the system.

- If you are designing a new system: Specify high-quality seals, proper reservoir breathers, and filtration levels that meet the cleanliness requirements of your most sensitive components.

Ultimately, treating your hydraulic fluid as a critical system component—not just a consumable—is the key to unlocking machine reliability.

Summary Table:

| Contaminant Type | Primary Sources | Key Damage Mechanisms |

|---|---|---|

| Particulate (dirt, metal) | Component wear, environment | Abrasive wear, scoring of parts |

| Water | Condensation, leaks | Reduced lubricity, rust, corrosion |

| Air | Leaks, cavitation | Spongy operation, surface erosion |

| Chemical | Fluid breakdown, wrong fluid | Sludge, varnish, seal damage |

Protect your hydraulic systems from the #1 cause of failure. Contamination control is critical for maximizing equipment lifespan and preventing costly downtime. KINTEK specializes in laboratory equipment and consumables, including filtration and fluid analysis solutions that help you maintain system integrity. Let our experts help you develop a proactive maintenance strategy. Contact KINTEK today to discuss your specific laboratory and equipment needs.

Visual Guide

Related Products

- Manual Lab Heat Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Custom PTFE Teflon Parts Manufacturer for PTFE Buchner Funnel and Triangular Funnel

People Also Ask

- What is a hydraulic press in simple words? Harness Immense Force for Shaping and Crushing

- What is the construction of a hydraulic press based on? Unlocking the Power of Pascal's Law

- What is the conclusion of a hydraulic press? Unmatched Force for Industrial Applications

- What are the parts of a manual hydraulic press? A Guide to Its Core Components and Operation

- What does a manual press do? Understand the Two Key Types for Your Lab or Industrial Needs