The muffle furnace method is a technique for high-temperature heating where the material being heated is physically isolated from the heating elements and any potential contaminants. This is achieved within a self-contained, insulated chamber, or "muffle," which ensures a clean, controlled, and uniform thermal environment.

The defining characteristic of a muffle furnace is not simply its ability to reach high temperatures, but its use of a protective barrier. This isolation prevents cross-contamination, protecting both the sample from the heat source and the heat source from the sample.

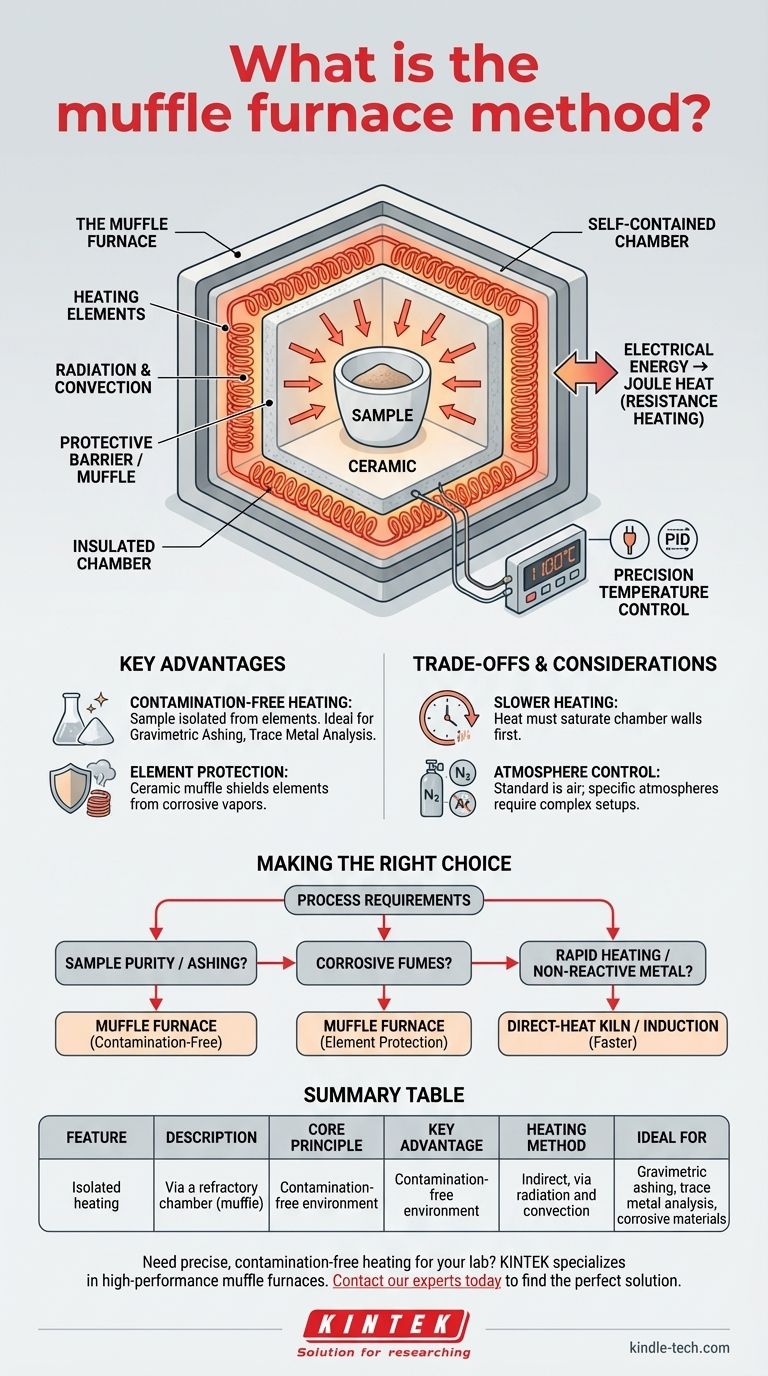

How a Muffle Furnace Achieves Isolated Heating

A muffle furnace operates on a simple yet highly effective principle of converting electrical energy into contained, radiant heat. This design is central to its primary function in research and industrial applications.

The Core Principle: Resistance Heating

The heat source in a modern muffle furnace is Joule heat, generated through electrical resistance. An electric current is passed through high-resistance heating coils, typically made of materials like Nichrome.

As electricity struggles to pass through these coils, it loses energy, which is released as intense heat.

The Role of the "Muffle"

Historically, the muffle was a physical ceramic box placed within a fuel-fired furnace to shield a sample from flames. In modern electric furnaces, the entire heating chamber acts as the muffle.

This chamber is constructed from a heat-resistant refractory material, such as ceramic. It performs two critical functions: it contains the heat for energy efficiency and isolates the sample from the heating elements.

Heat Transfer and Uniformity

The heating elements heat the walls of the muffle chamber. These hot walls then transfer heat to the sample inside primarily through convection and radiation.

This indirect method ensures that the sample is heated evenly from all sides, providing excellent temperature uniformity, which is critical for repeatable results in material testing and ashing.

Precision Temperature Control

Modern furnaces use a thermocouple to measure the internal temperature accurately. This information is fed to a PID controller (Proportional-Integral-Derivative).

The PID controller precisely regulates the power sent to the heating elements, often using solid-state relays for quiet, reliable operation. This allows the furnace to maintain a specific temperature with very little fluctuation.

Understanding the Key Advantages and Trade-offs

Choosing a muffle furnace involves understanding its distinct benefits, which are directly tied to its isolated design, as well as its limitations compared to other heating methods.

Key Advantage: Contamination-Free Heating

Because the sample never comes into contact with the heating elements, the risk of contamination is virtually eliminated.

This makes the muffle furnace essential for applications like gravimetric ashing, where a clean burn-off is required, or trace metal analysis, where any external impurity would compromise the results.

Key Advantage: Element Protection

The muffle design also works in reverse, protecting the heating elements from the sample.

When heating materials that release aggressive gases or corrosive vapors, the ceramic muffle acts as a shield, significantly extending the life of the heating coils.

Common Misconception: Heating Speed

While muffle furnaces are highly efficient at maintaining high temperatures, their heating rate can be slower than direct heating methods like induction or open-flame furnaces.

The heat must first saturate the chamber walls before it can be radiated to the sample, introducing a slight thermal lag.

Consideration: Atmosphere Control

A standard muffle furnace heats samples in the presence of air, facilitated by an air inlet and an exhaust port.

If an application requires heating in a specific atmosphere (such as nitrogen or argon) or in a vacuum, a specialized and significantly more complex furnace is necessary.

Making the Right Choice for Your Application

Selecting the correct heating method depends entirely on the specific requirements of your process, particularly regarding purity, sample reactivity, and temperature uniformity.

- If your primary focus is sample purity and ashing: The muffle furnace is the definitive choice due to its contamination-free environment.

- If your primary focus is heating materials that release corrosive fumes: A muffle furnace is essential for protecting the equipment and ensuring its longevity.

- If your primary focus is simply rapid, high-temperature heating of a non-reactive metal: A simpler, direct-heat kiln or induction furnace might be a faster or more cost-effective solution.

Ultimately, the muffle furnace method is the standard for anyone requiring precise, uniform, and clean high-temperature thermal processing.

Summary Table:

| Feature | Description |

|---|---|

| Core Principle | Isolated heating via a refractory chamber (muffle) |

| Key Advantage | Contamination-free environment for samples |

| Heating Method | Indirect, via radiation and convection |

| Ideal For | Gravimetric ashing, trace metal analysis, heating corrosive materials |

Need precise, contamination-free heating for your lab?

KINTEK specializes in high-performance muffle furnaces designed for applications where sample purity and temperature uniformity are critical. Our equipment ensures reliable results for gravimetric ashing, material testing, and more.

Contact our experts today to find the perfect solution for your laboratory's needs.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Is firing the same as sintering? A Guide to Mastering Thermal Processing

- What are the benefits of a benchtop muffle furnace? Achieve Precise, Compact Thermal Processing

- What is the temperature of a laboratory oven? Choose the Right Type for Your Application

- What is ashing in analytical chemistry? A Guide to Sample Preparation for Elemental Analysis

- What are the different types of laboratory furnaces? Find the Perfect Fit for Your Application

- What role does a muffle furnace play in the thermal treatment and synthesis of Li2.5Y0.5Zr0.5Cl6? Master Your Synthesis

- Why is a high-temperature muffle furnace required for the preparation of calcium oxide nanoparticles? Expert Guide

- What are the advantages of using a tempering furnace for FATT50? Precision Control for Superior Steel Toughness