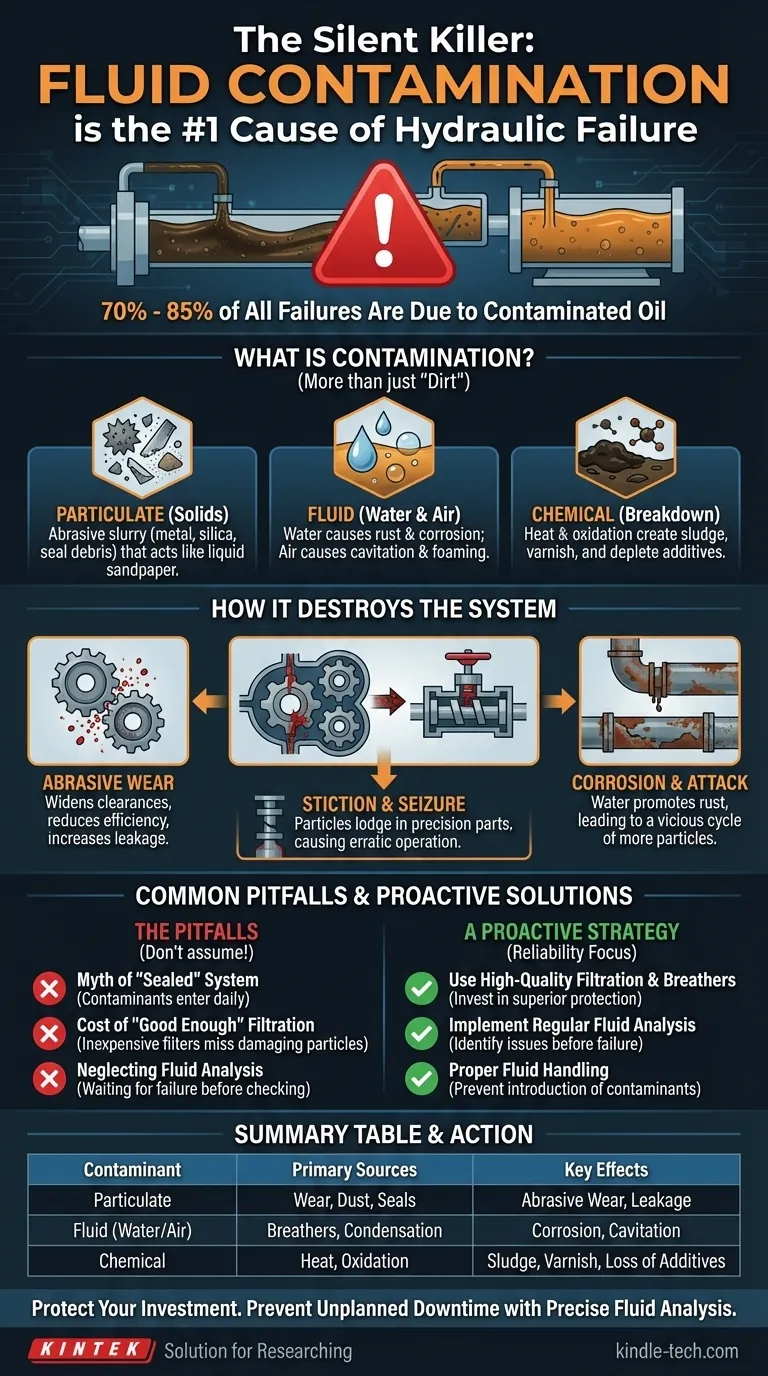

By a wide margin, the single number one cause of failure in hydraulic systems is fluid contamination. Industry studies consistently show that between 70% and 85% of all hydraulic problems and breakdowns can be traced back to contaminated oil. This isn't a single event, but a continuous process that degrades components over time through abrasion, corrosion, and chemical reactions.

The central takeaway is this: Hydraulic failure is rarely a sudden, unpredictable event. It is most often the result of a slow, preventable decay caused by contaminants in the fluid. Therefore, managing fluid cleanliness is the most critical activity for ensuring system reliability.

What Exactly Is Hydraulic Contamination?

To effectively combat contamination, you must first understand its forms. It is far more than just visible dirt or grime in the oil.

Beyond Simple "Dirt"

Contamination is any foreign substance in the hydraulic fluid that can harm the system's performance and longevity.

These substances can be solid particles, liquids like water, or even gases like air. They fundamentally alter the fluid's properties and its ability to do its job.

The Three Main Types of Contaminants

We can group these harmful substances into three primary categories.

Particulate Contamination (Solids) This is the most well-known type. It includes tiny metal fragments from component wear, silica from airborne dust, and elastomers from aging seals. These particles become suspended in the fluid, turning it into a destructive, abrasive slurry.

Fluid Contamination (Liquids & Gases) This category includes water, which enters through seals and reservoir breathers. It also includes air, which can cause foaming and cavitation, and even the accidental mixing of incorrect fluid types.

Chemical Contamination (Breakdown) This is a result of the fluid itself degrading. High temperatures cause oxidation, creating sludge and varnish. Additives within the oil can also deplete over time, reducing its protective qualities.

How Contamination Destroys a System

Contaminants don't cause one single type of failure. Instead, they attack the system from multiple angles, leading to a cascade of problems.

Abrasive Wear: The Sandpaper Effect

Hard particles like silica and metal are the most destructive. As they are forced through the tight clearances of pumps, motors, and valves, they act like liquid sandpaper.

This constant abrasion wears down critical surfaces, widening the clearances between moving parts. The result is a loss of efficiency, increased internal leakage, and eventually, total component failure.

Stiction and Seizure

Extremely fine particles, often too small to see, can become lodged in the narrow passages of precision components like servo and proportional valves.

This buildup causes stiction, where the valve spool sticks instead of moving smoothly. This leads to erratic, unreliable machine operation and can eventually cause the component to seize completely.

Corrosion and Chemical Attack

Water is a catastrophic contaminant. It promotes rust and corrosion on metal surfaces, which in turn generates even more abrasive particulate contamination—a vicious cycle.

Water also facilitates hydrolysis, a chemical breakdown of the oil's additives, stripping it of its anti-wear and anti-corrosion properties.

Common Pitfalls and Misconceptions

Many well-intentioned maintenance programs fail because they are based on a misunderstanding of how contamination works and where it comes from.

The Myth of a "Sealed" System

No hydraulic system is truly sealed. Air, moisture, and dust are constantly trying to get in.

The cylinder rod is a primary entry point, dragging in microscopic contaminants with every cycle. The reservoir breather cap is another, pulling in airborne particles and humidity as the fluid level changes.

The Cost of "Good Enough" Filtration

Choosing a filter based on the lowest initial price is a classic mistake. An inexpensive filter may capture large, obvious particles but allow the much more damaging microscopic particles to pass right through.

This approach saves a small amount on maintenance parts but leads to enormous costs in premature component replacement and unplanned downtime.

Neglecting Fluid Analysis

Waiting for a system to show obvious symptoms before checking the oil is like waiting for a heart attack before seeing a doctor.

Regular fluid analysis is the equivalent of a blood test for your machine. It provides a detailed report on the type and quantity of contaminants, allowing you to identify and fix problems before they cause a catastrophic failure.

A Proactive Strategy for Reliability

Your approach to contamination control directly determines the lifespan and reliability of your equipment. A proactive mindset is required.

- If your primary focus is maximizing equipment lifespan: Prioritize prevention by using high-quality filtration, high-performance desiccant breathers, and proper fluid handling techniques from day one.

- If your primary focus is reducing operational downtime: Implement a regular fluid analysis program to detect rising contamination levels and wear metals, allowing you to schedule maintenance before a failure occurs.

- If your primary focus is cost-effective maintenance: Invest in superior filters and breathers, as the cost is minimal compared to replacing a single pump or valve damaged by contamination.

Ultimately, managing the condition of your hydraulic fluid is the single most effective action you can take to manage the health of your entire system.

Summary Table:

| Contaminant Type | Primary Sources | Key Effects on System |

|---|---|---|

| Particulate (Solids) | Component wear, dust, seal debris | Abrasive wear, loss of efficiency, internal leakage |

| Fluid (Water/Air) | Reservoir breathers, cylinder rods, condensation | Corrosion, cavitation, foaming, additive breakdown |

| Chemical (Oil Breakdown) | High temperatures, oxidation | Sludge, varnish, loss of protective additives |

Protect your investment and eliminate unplanned downtime. The reliability of your hydraulic systems depends on fluid purity. KINTEK specializes in laboratory equipment and consumables for precise fluid analysis, helping you monitor contamination levels and prevent costly failures.

Contact our experts today to discuss a proactive maintenance strategy tailored to your laboratory's needs.

Visual Guide

Related Products

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Manual Lab Heat Press

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the role of a laboratory hydraulic press in the fabrication of transition metal boride pellets? | KINTEK

- How many tons can a hydraulic press do? From 5-Ton Benchtop Units to 75,000-Ton Industrial Giants

- What is the function of a precision hydraulic press in MEA fabrication? Optimize Fuel Cell Bonding and Efficiency

- What is the construction of a hydraulic press based on? Unlocking the Power of Pascal's Law

- What types of hydraulic press systems are used for research? Discover Pellet, Hot, and Isostatic Solutions

- How do laboratory hydraulic presses and molds ensure accuracy in high-strength gypsum concrete testing?

- What product is made from press forging? Manufacturing Critical Components for Aerospace, Automotive, and Energy

- How is a laboratory hydraulic press used to evaluate the mechanical performance of nano-modified concrete? Expert Guide